Updated May 13, 2021

There are certainly a lot of buzzwords and trends that follow along with Industry 4.0. It can be difficult for manufacturers to grasp the concept and determine how it is at all possible to adopt industry 4.0 solutions. After all, “Industry 4.0” is a vague overarching concept. It can be difficult to think about it in practical terms and begin rolling out a roadmap for integrating it into your business’ vision.

In discussing how you can get started with Industry 4.0, we should first define what it is. From our full guide on the topic:

Industry 4.0, also known as the Fourth Industrial Revolution, or 4IR, is an all-encompassing term to refer to the way computers, data and automation are evolving and coming together to change the way work happens, and in particular, manufacturing.

This isn’t an actionable strategy, but rather a new generation of manufacturing, made possible via smart technology, including IoT, to drive connectivity, processing of information, and automation.

Developing an Industry 4.0 Strategy

Depending on the nature of your industry, business, and operations, there are an unlimited number of use cases to pursue, as well as a large variety of industry 4.0 technologies to deploy. It would be impossible to instruct you on getting started. We’ll take a broader approach based on establishing the right infrastructure to support your Industry 4.0 initiatives.

In this regard, we will be discussing the foundation of Industry 4.0: Data.

Industry 4.0 is wholly concerned with connecting people, systems, and equipment to communicate, monitor, and inform. This enables manufacturers to develop a better understanding of their operation, and support use cases that drive process optimization, predictive maintenance, automation, and more.

All these use cases are built upon having the right operational data that is democratized across the organization and accessible both by stakeholders, equipment, and systems that require the information to act upon.

Getting Connected: Your People, Systems, and Equipment

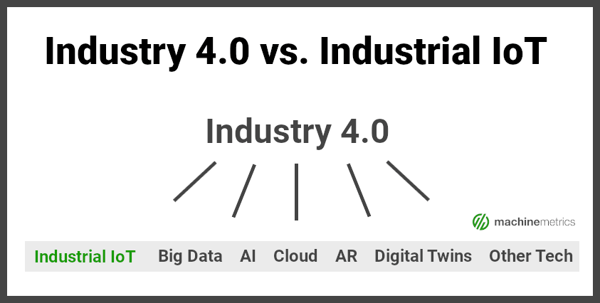

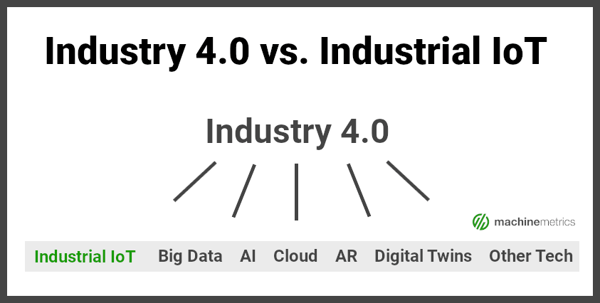

One term often used in the same sentence as Industry 4.0 is IIoT, or the Industrial Internet of Things. The primary difference between the two concepts, as explained in our article, is that IIoT is one of many forms of technology that falls under the larger umbrella of the industrial revolution that is Industry 4.0.

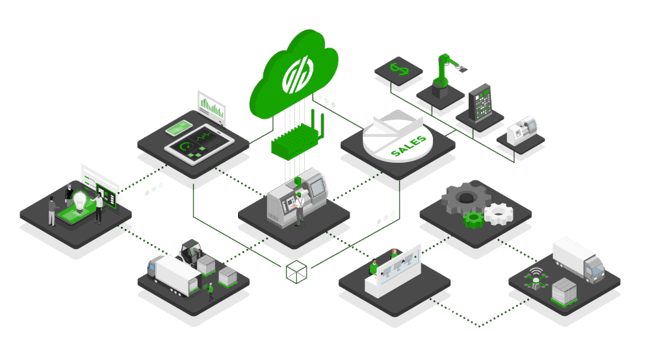

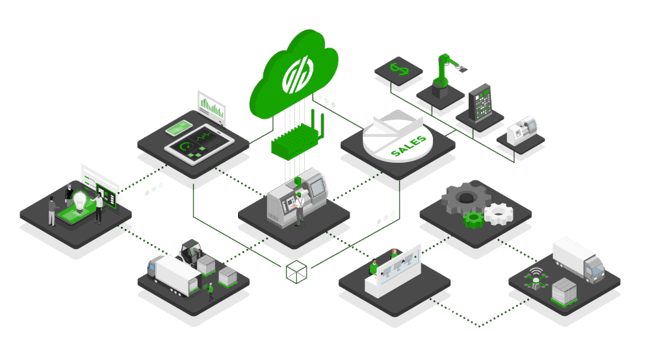

IoT is concerned with getting the right information to the right person (or system/machine) at the right time. As a manufacturer, connecting your systems, people, and equipment is the basis of this connected network that enables the aggregation and communication of data, giving you incredible control of the shop floor and providing a foundation for continuous improvement.

The next questions would rightfully be: How do I begin connecting my operation? Where do I start?

The Heart of Production

The heart of your operation includes the people and equipment most responsible for manufacturing goods: The machines and people on the shop floor.

As a manufacturer, these are the most important sources of data you have available to you. If you can tap into the data locked within the operation on the shop floor, you will have complete visibility and control, and will be able to use this data to create visibility for other stakeholders, enable process optimization, and drive better management of other activities such as quality, maintenance, planning, and more.

Step One: Machine Connectivity

The equipment on the shop floor tells a production story more accurate than any job log, excel sheet, or whiteboard. With an Industrial IoT Platform like MachineMetrics, you can connect directly to machine assets, automatically transform the data, and visualize it in real-time.

Learn more about machine data collection.

Step Two: Contextual Operational Data

Machines can tell you what happened, but they can never tell you why. This human component is integral for explaining a variety of instances on the shop floor. With an easy way to document production activities, this data adds context to the machine data, providing a pivotal layer for better understanding the equipment performance.

Step 3: Connected Systems

Aggregating production data can be an easy first step into Industry 4.0. You can have instant, real-time visibility into your most important metrics, enabling you to ensure production goals are met and issues are resolved as soon as possible.

However, this opens a whole world of possibilities, as you can use this data to inform systems outside of your machine monitoring of Industrial IoT platform. For example, you can use your production data to inform the maintenance team of machine downtime in a CMMS, provide quality managers with scrap part numbers, and even develop baselines of important metrics that enable your team to price more accurately and better handle customer demand.

Learn more about MachineMetrics integrations.

Industry 4.0 Begins Here

Take your first steps to Industry 4.0 with a platform that can easily connect your equipment and people, while providing the data foundation you need to extend the value to other systems and processes.

MachineMetrics provides an out-of-the-box solution to connecting your assets, providing complete visibility to the shop floor, and offering tools for analyzing production performance to identify bottlenecks and opportunities.

A Case Study on Building the Industry 4.0 Foundation with Data

Since deploying a production tracking solution, Fairview now has live data from their operations 24/7 providing both operators and the back office with instant visibility into all their machines to dramatically increase efficiency.

Within the below video, Michael touches upon a variety of benefits his organization has experienced, including:

- Real-time production data for complete control of the shop floor

- The competitive advantage MachineMetrics provides for Fairview when attracting customers

- Data accessibility across all devices, whether on the shop floor, back office, or at home

- The MachineMetrics and Epicor ERP integration

- World-class customer service

- Fast and easy implementation

Learn how Fairview Machine was able to get complete control of the operation in this video case study:

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments