The concept of cloud computing has been around for decades. And it was originally derived from the flow charts and diagrams used to envision the early foundations of the internet. Even then, the concept of linking many devices as an accumulation of computing resources with increased analytical power was seen as valuable.

What is Cloud Software?

Simply defined, cloud computing is a way to deliver computing service on-demand through the internet. The cloud can be public, delivering a defined service to multiple users, called the public cloud. Or the mode of cloud service can be a private cloud, delivering IT and other services over a company’s private IT structure.

Using one of these two models in manufacturing, companies can utilize a service provider’s offerings ranging from Software as a Service (SaaS) where users utilize the provider’s applications, Platform as a Service (PaaS) where users are provided a development environment, and Infrastructure as a Service (IaaS) where users can develop their own software and operating system while using storage, backup and security provided by the cloud service provider.

Further reading: A Manufacturer's Guide to Cloud Computing

Leveraging Cloud Manufacturing Software

For many manufacturing companies, cloud-based manufacturing software offer benefits unobtainable and more cost-effective than in-house IT. This is critical for web-based companies where access from any location is vital. But it is becoming increasingly desirable for manufacturers who are at the forefront of Industry 4.0 technologies, such as the Industrial Internet of Things, that are delivering productivity gains previously unheard of.

Benefits of introducing manufacturing software that lives in the cloud:

- Access to the Latest Advancements – For small to medium sized companies, cloud computing offers access to the latest software and continuous automatic updates to that software as they become available. This levels the playing field and provides small to medium sized business (SMB) an opportunity to be competitive on par with larger entities within their industry, especially when deploying technology such as IIoT devices and software.

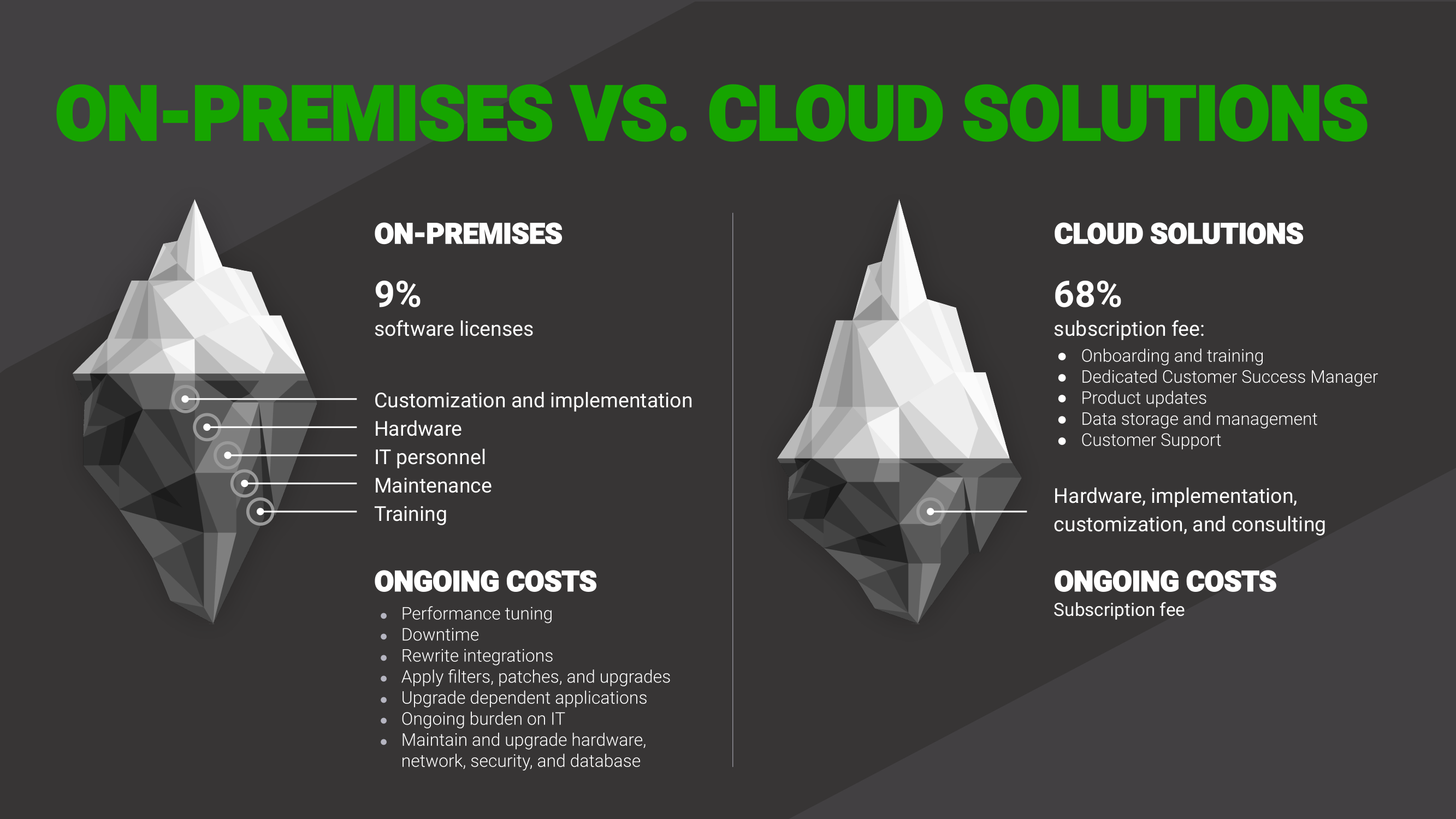

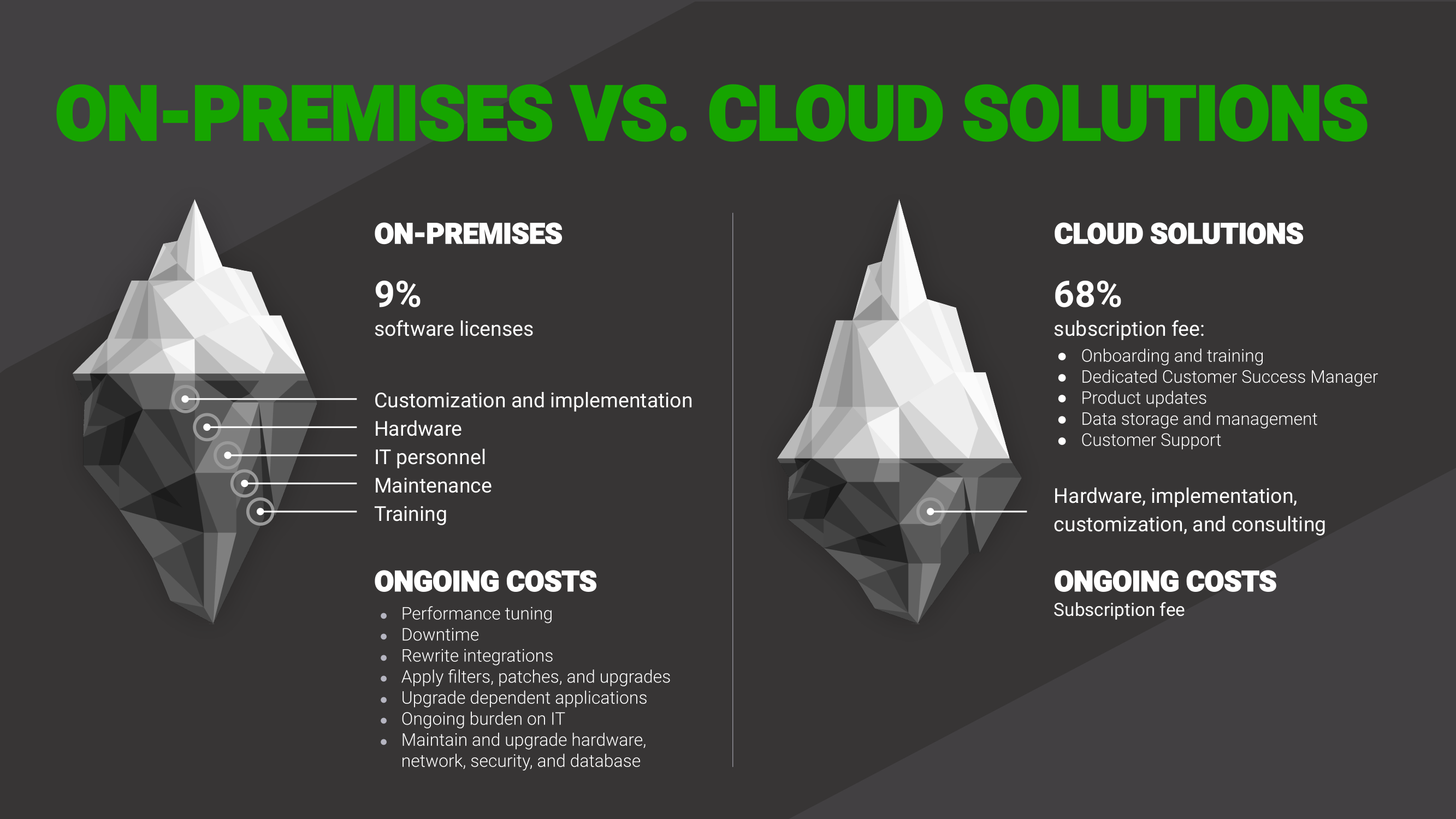

- Lower Upfront Costs – Cloud based computing services usually offer much lower startup costs, making entry more accessible by SMBs. Many service providers offer subscription-based pricing and services that can be tailored to pride only what is needed, making the service more cost effective as well.

- Scalability – Because cloud-based service providers often offer pay-for-what-you-need functionality, services through the cloud are highly scalable. In traditional IT, capital expense and skills often lag when companies encounter a steep growth curve, holding back and delaying advancement. With cloud computing, service providers can handle the increase proportionally as a company experiences growth or deploys deeper levels of IoT devices to bring additional legacy equipment into the data stream.

- IoT ready – Cloud computing’s speed and cost seem ready made for the introduction to IoT technology. With the ability to manage a production floor with connected devices and with dashboards and KPIs accessible through tablets and phones as well as operator interfaces, data is standardized, and production floor response can be real-time to improve productivity.

- Less In-House IT Required – A study by Gartner shows that companies can spend as much as 75% of their IT budget for onsite IT maintenance. By utilizing cloud-based service providers, manufacturing companies can lower their IT budget to devote resources and cash to other needs. This is especially beneficial to producers who are SMBs with limited resources and less availability to funding. These services are also faster to implement, making services more readily available compared to long-term onsite deployments.

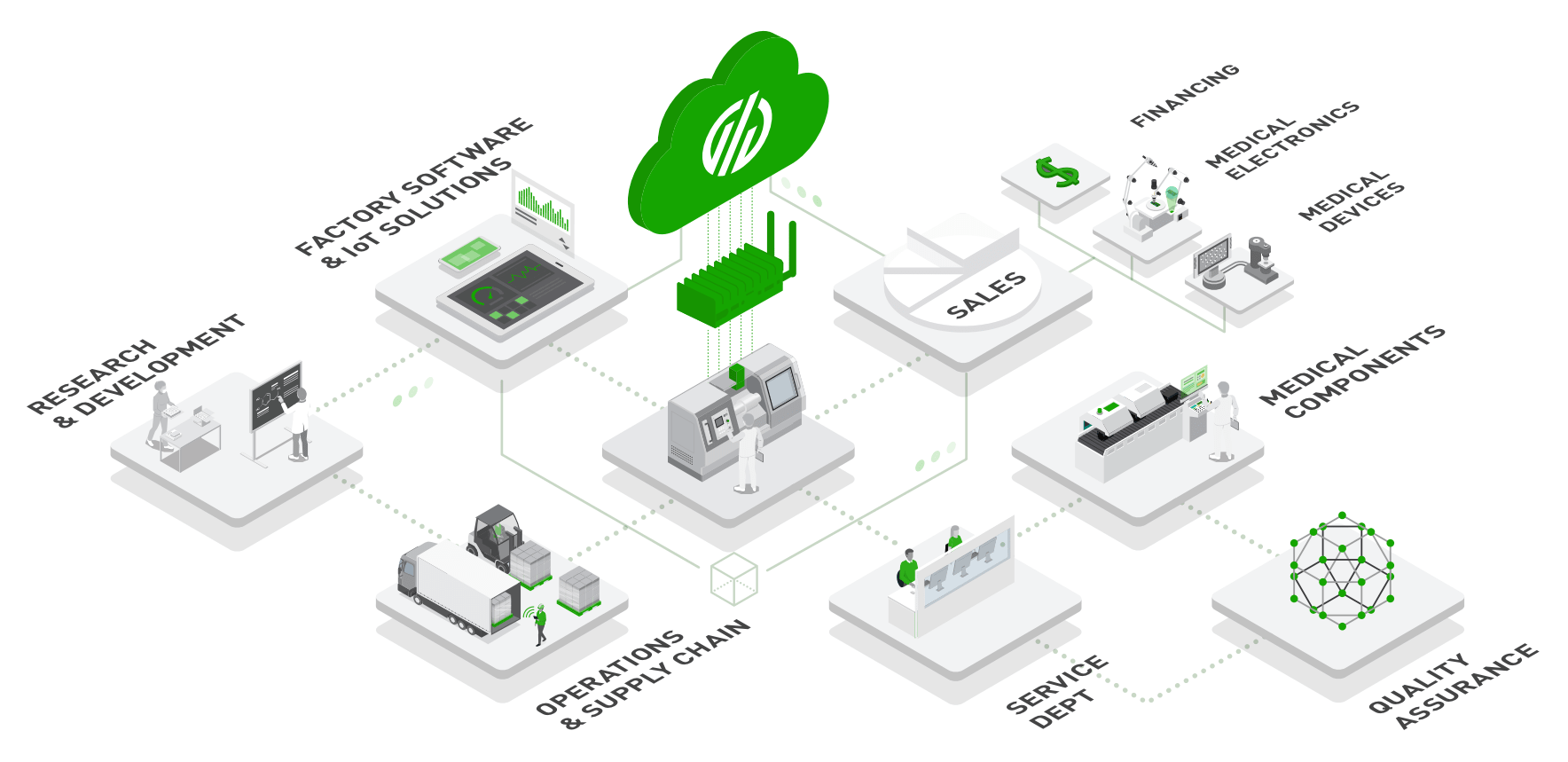

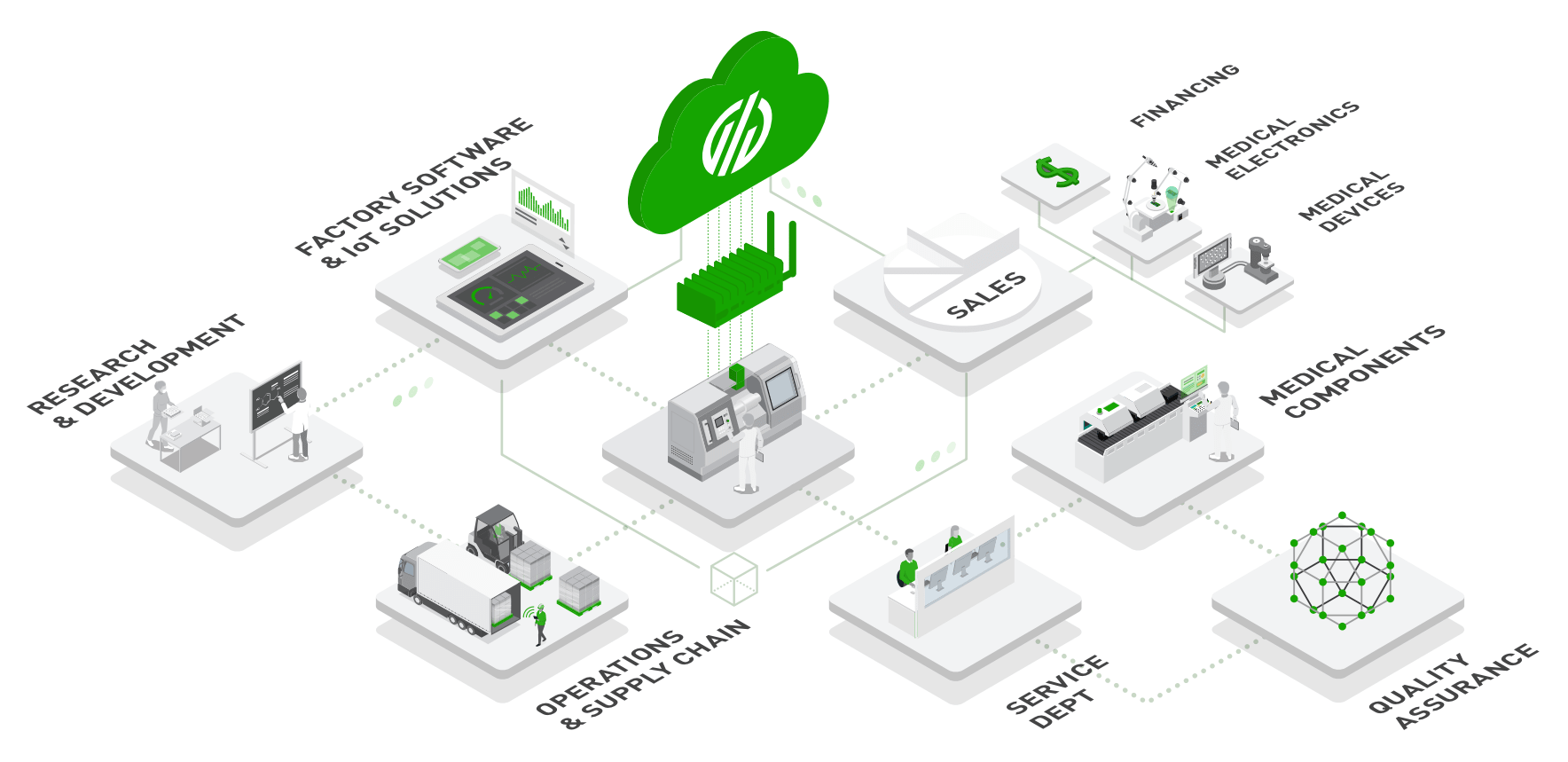

- Deeper Integration – Cloud computing services offer factories and producers a way to integrate systems at a deeper level. Using APIs, POS, PMS, and CRM systems as well as web forms and other applications can be integrated to create a single system customized to the company. This is also true of advanced technology such as Industrial IoT which can be integrated with many ERP systems offered today to fully connect, digitize and organize the data offered by connectivity at the enterprise level.

- Accessibility – The ability to access data and critical KPIs from anywhere offers companies the opportunity for real-time collaboration and remote visibility, decision-making and action. As advanced robotics and Industrial IoT converge, this offers many manufacturers the opportunity to move toward partial “lights out” manufacturing modes where a large part of production is performed by unattended machines.

Should You Use the Cloud?

A study by Goldman Sachs shows that spending for cloud computing grew at a 30% compound annual growth rate (CAGR) from 2013-2018 while enterprise IT grew at only 5%. However, onsite IT is still a viable, and in some cases preferred, mode of operation for many companies. Of those companies utilizing onsite IT, reasons ranged from security concerns (73%) to control over IT resources (38%) to compliance issues(38%).

For companies utilizing onsite IT systems, many do so based on the perceived disadvantages of the cloud. And the advantages of onsite IT will vary from industry to industry as well as from large companies to small. However, some of the benefits of onsite IT include:

- Control Over Backup – The company maintains physical control over backup, important for large scale companies such as banks where timing for data backup is crucial.

- Security – The company maintains critical data in-house. For companies with a large throughput of proprietary formulations or patent data such as big pharma, keeping data in-house means less threat from outside security breaches.

- No Internet Required – Recent DDOS attacks have left many domains without service for several hours. And new reports indicate that in 2019 Q1 alone, DDOS attacks of 100Gbps or larger increased by 967% compared to the same period a year ago.

- Cost on Scale – Cost of cloud vs onsite is often related to scale. In companies with a high-scale IT, such as e-commerce giants, the cost of services such as AWS can exceed the cost for in-house IT.

- Vendor Going Out of Business - Any third-party provided service is always at risk of disappearing if the company ceases operation. While service and data can be moved to another provider, the risk is heightened as so many service providers are small to medium sized businesses themselves, often in competition with AWS and other large entities.

Efforts are underway to address some of the disadvantages of cloud computing. One approach is the use of Cloud Access Security Brokers (CASB). CASBs act as a gateway between cloud providers and users to implement enterprise security policies. They can also help companies adhere to newly passed legislation for data security compliance.

As Industry 4.0 technologies advance and security and compliance issues recede, the move to higher adoption of cloud computing will continue. For technologies such as Industrial IoT, the advantages above allow connected enterprises that encompass whole factories to deliver data and analysis for improved efficiency. These cloud-based systems will impact how factories operate over production, inventory control, maintenance and scheduling. And the ability to customize, scale, control and deploy in an agile and competitive fashion means that the cloud a company uses can be tailored to meet a company's specific goals and deliver that company’s unique value to its clients.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments