Kepware has long been synonymous with industrial connectivity. Having been founded in the mid-1990’s, they have successfully helped connect a large variety of industrial equipment across a wide range of industries, giving a multitude of engineers the tools to successfully roll out M2M projects.

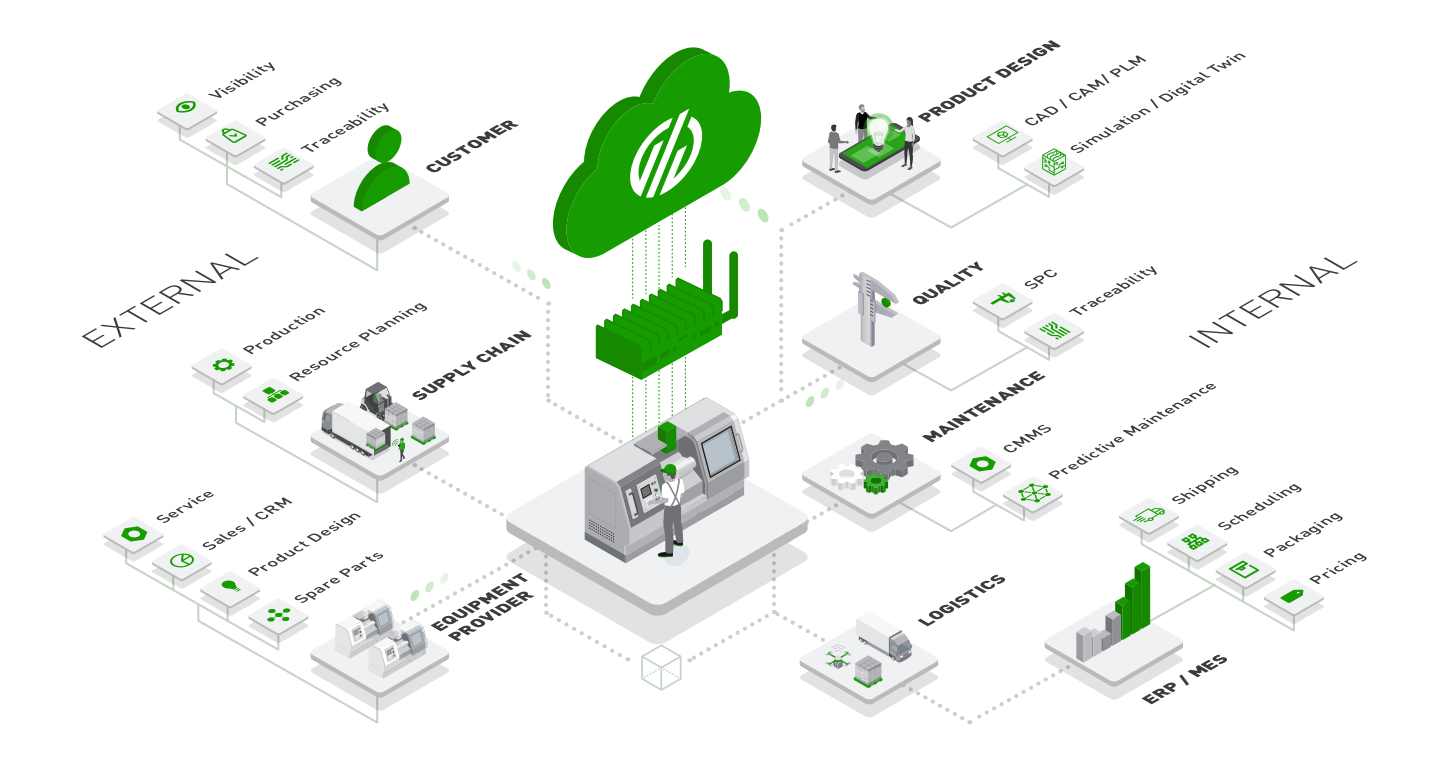

However, with the onset of Industry 4.0 and advancements in the field of industrial connectivity, new solutions have arisen to meet the growing demands of manufacturers. These manufacturers are seeking solutions to quickly and easily connect their equipment and receive immediate insights to make performance-enhancing decisions across their operations.

If this is you, perhaps you are in search of a Kepware alternative.

New market solutions are driving the next generation of connected equipment, helping manufacturers connect their equipment and use data faster and more effectively than before. These solutions are allowing manufacturers to get deeper insights off their equipment to reduce costs, increase capacity, and even develop new business models.

In the below review of the Kepware solution, we outline a variety of areas in which there is a more ideal option available:

Kepware is “Hands-On”

Kepware requires you to figure out what hardware to use, makes you run an installer, and puts the burden on you and your team keep it all updated (ie. “You install it and you manage it with your dollars and time”). On the other hand, MachineMetrics is centrally managed by the cloud so it acts as an automatically updated edge platform (ie. hands-off) that connects in a matter of minutes. In this regard, there is no need for an entire team of engineers or technical resources to install and maintain a system.

Connectivity Options and Depth of Connectivity

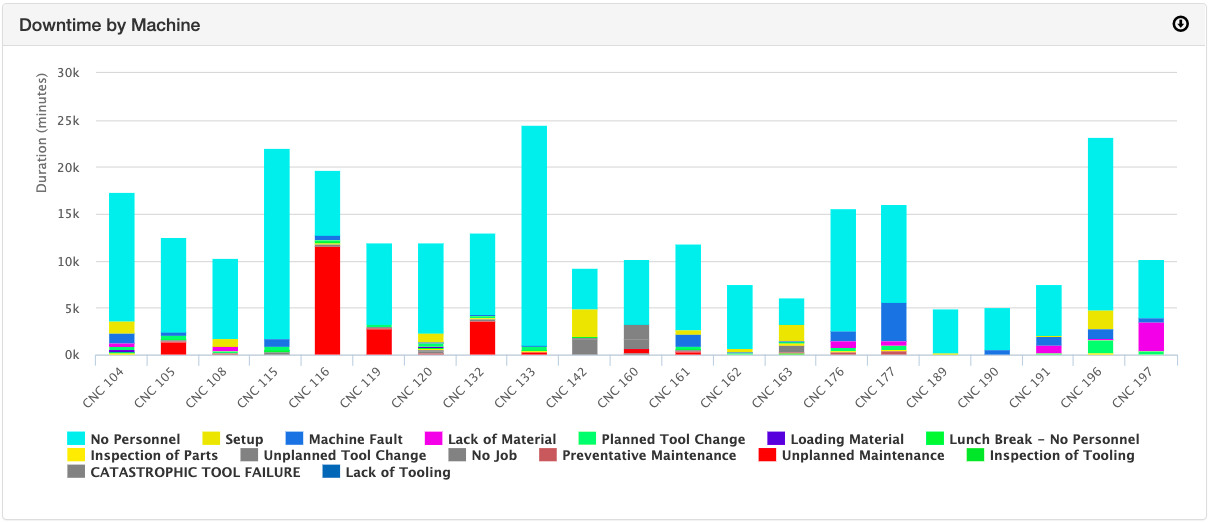

Kepware connects to a lot of industrial PLCs. After all, the organization has been around since the 90’s. However, where Kepware lacks is in the depth of its integration to CNC machines. MachineMetrics is a lot better at getting data off of CNC machines than Kepware, in terms of the depth, speed, and ease of collecting the data.

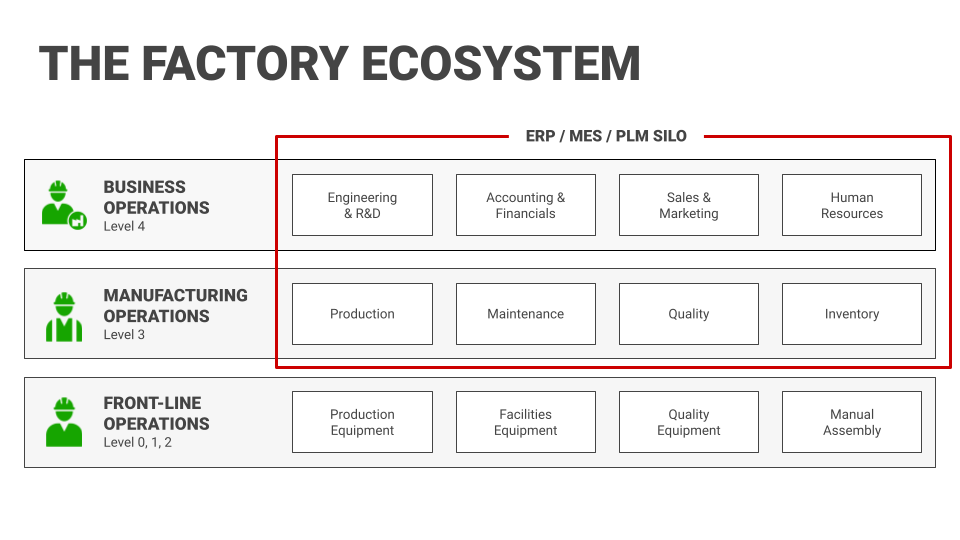

Connectors vs. Platform

MachineMetrics is a true edge platform, whereas Kepware, as a standalone solution, is simply a variety of connectors. The problem with connectors is that the user has to write the code to transform the data from the connector. Essentially, they must contextualize the data, map the data, and get it into a structure that is consumable. MachineMetrics automates all of this, so that when a customer connects our edge device, they get the connector, data transformation (or contextualization), the dashboards, diagnostic tools, reports, etc. all packaged in an application (or applications) right out of the box. Furthermore, with MachineMetrics, they will have centralized management of the connections including troubleshooting, updating, diagnostics, etc. which is managed in the cloud infrastructure.

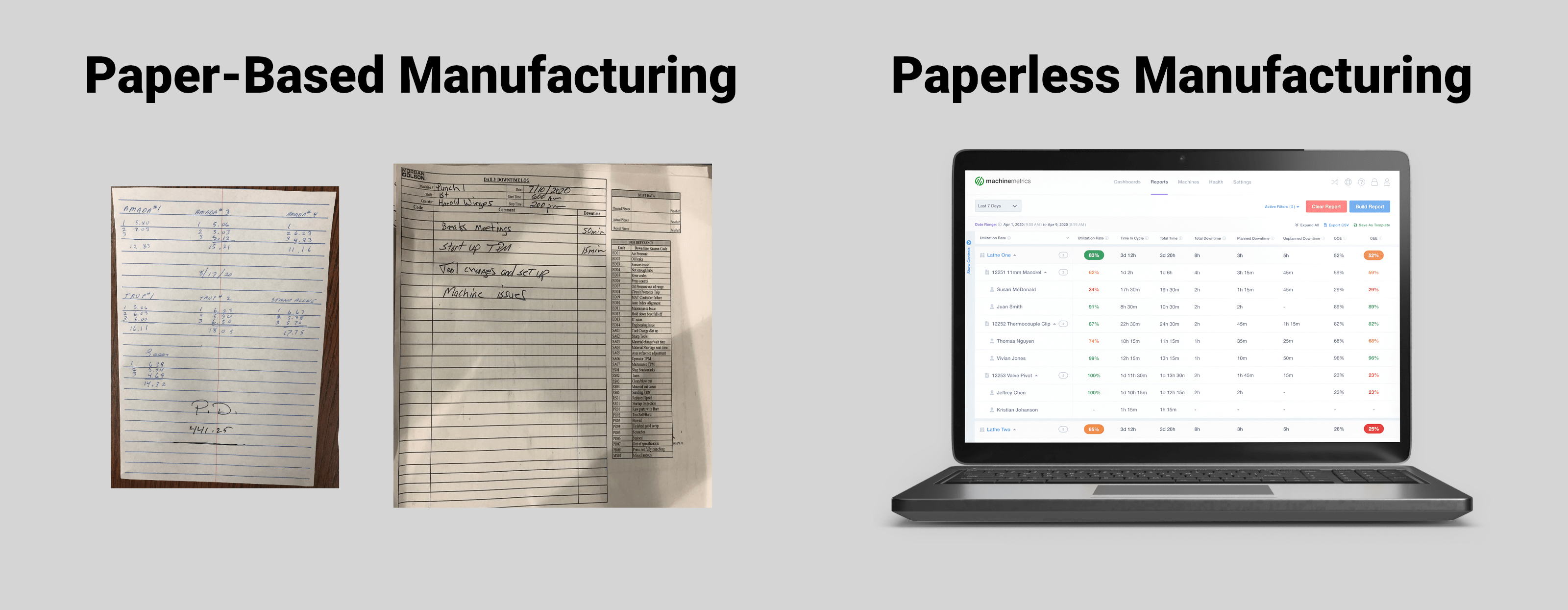

Data Transformation

Kepware can expose your machine data and make it accessible, but with Kepware alone you will not be able to transform it into a common data structure. Even with a solution like ThingWorx, it would require a lot of technical work to use the data effectively. On the other hand, MachineMetrics combines both elements to automatically transform your data into consumable reports.

Time to Value

Similar to the connector and platform discussion above, MachineMetrics can simply send an edge device to a customer and have them up and running in minutes. The data that they collect will be automatically transformed into insights via reports and dashboards. There is no need for complex technical configurations to set up connectors, nor is it necessary to leverage another piece of software to get insight into the collected data. With Kepware, you’re looking at a matter of months, or years before getting value or realizing a return on your initial investment. With MachineMetrics, it can be a matter of minutes. Simply connect the Edge device to the machine, configure the application, and you’re done.

Introducing a Modern Machine Data Collection Solution

When it comes to collecting, transforming, and getting value from machine data, MachineMetrics is the standalone leader, helping hundreds of manufacturers connect thousands of machines across the globe.

MachineMetrics...

- Easily connects to any type of machine asset regardless of make, model, age, protocol, or control system.

- Automatically maps your data items to a common data structure and provides immediate insight via out-of-the-box apps, reports, and dashboards.

- Offers a deep integration with CNC equipment, connecting directly to the controls of the CNC to extract high quality

- data fast and easy.

- Has centralized edge management capabilities that automatically update. No need for an IT team to maintain your devices and sustain software.

- Includes several integration methods for hardware, meaning installation and value attainment can occur in minutes, not months.

- Has all connectors included, with no additional fees.

Don't believe us? Compare Kepware and MachineMetrics head-to-head by booking a demo with our team today.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments