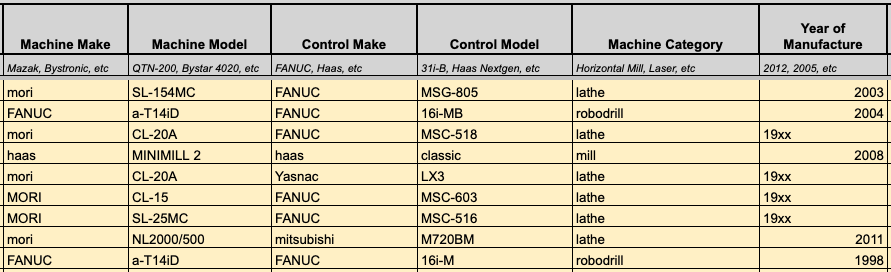

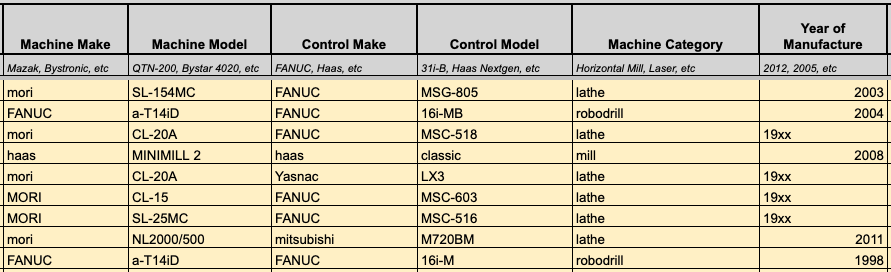

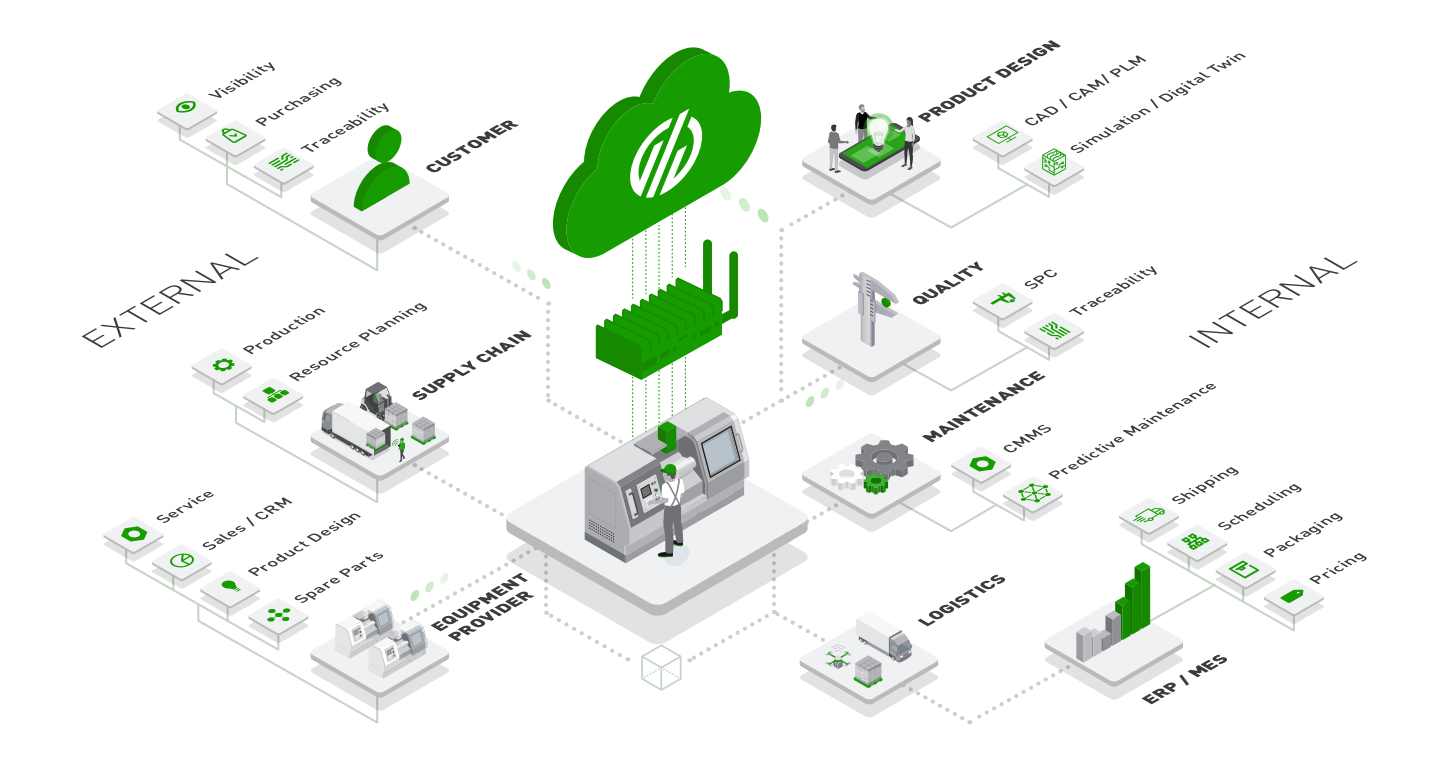

One of the most common questions we get from manufacturers: What data can I collect from my equipment and operations using MachineMetrics?

The answer will rely on the make and model of the equipment and control in question. One of the hallmarks of our platform is the depth and breadth of machine connectivity. Not only do we connect to any make, model, and age of discrete manufacturing equipment (turning, milling, stamping, robots, paint lines, belt sanders, manual welders, etc.), but we also have deep connectivity capabilities to capture the most relevant data points.

Most machine monitoring platforms are unable to connect and capture data at such depth and across such a wide array of equipment. Our connectivity capabilities are a testament to the work our team has put into building the infrastructure required to not only capture different types of data but also ensure the data is standardized to enable actionability.

Want to go deeper on machine connectivity? Read our complete guide.

If you’re interested to know exactly what we can do with your equipment, get in touch with our team.

Legacy vs. Modern Equipment

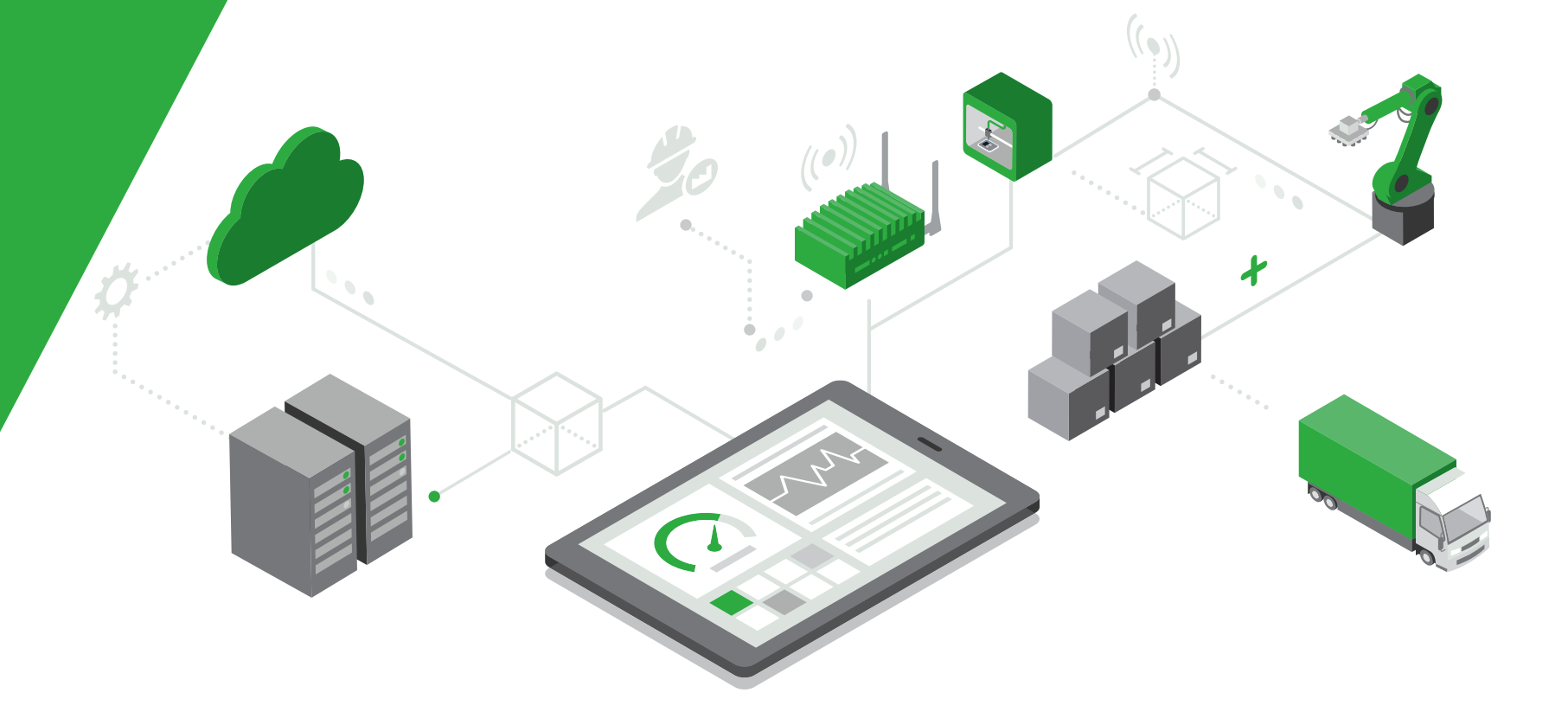

For the purpose of simplicity, there are two options for machine connectivity: direct machine connections and I/O connections. Choosing between the two connectivity options will depend on the machine and control in question, and will likely impact the types of data that can be collected.

I/O Connections

I/O connections are used for equipment that is unable to transmit data via an industrial protocol. This is often the case with legacy equipment, but can also occur with modern equipment that does not provide a needed data point via a direct connection. A MachineMetrics I/O module is used to extract the data and send it to the edge device.

A MachineMetrics I/O Connectivity Kit.

A MachineMetrics I/O Connectivity Kit.

Direct Machine Connections

If a machine is capable of transmitting data via an industrial protocol, such as MTConnect or Fanuc FOCAS, you can directly connect and extract data over the network. The MachineMetrics edge device can be connected via an ethernet port, directly to the machine’s PLC, or to a relevant data port.

This is the standard method of data capture for modern equipment. Also, it will likely yield more data points than an I/O connection. Once again, much here is reliant on the machine and control in question. While some brands may offer a large amount of data, others may offer few.

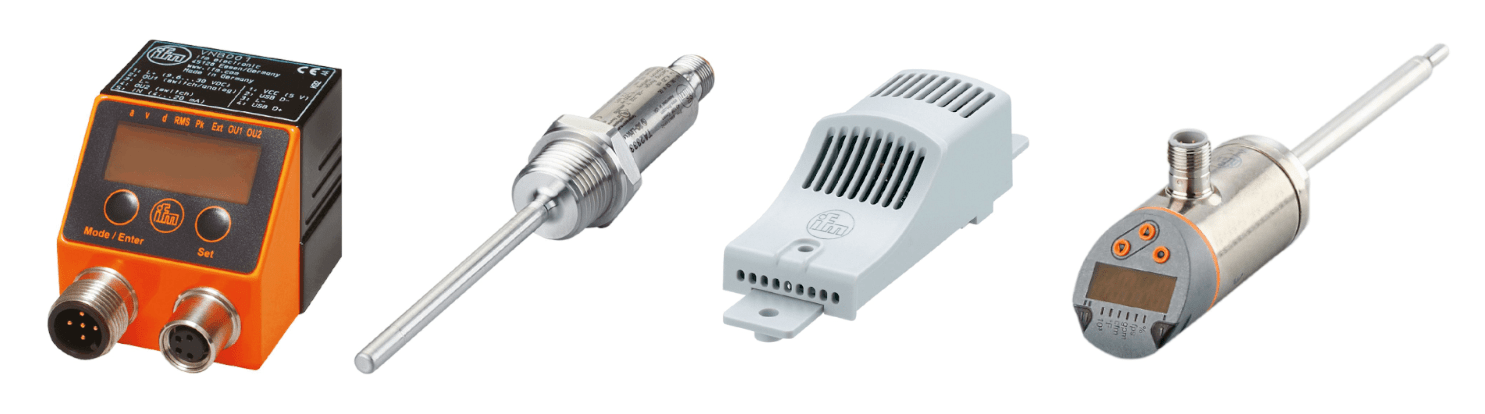

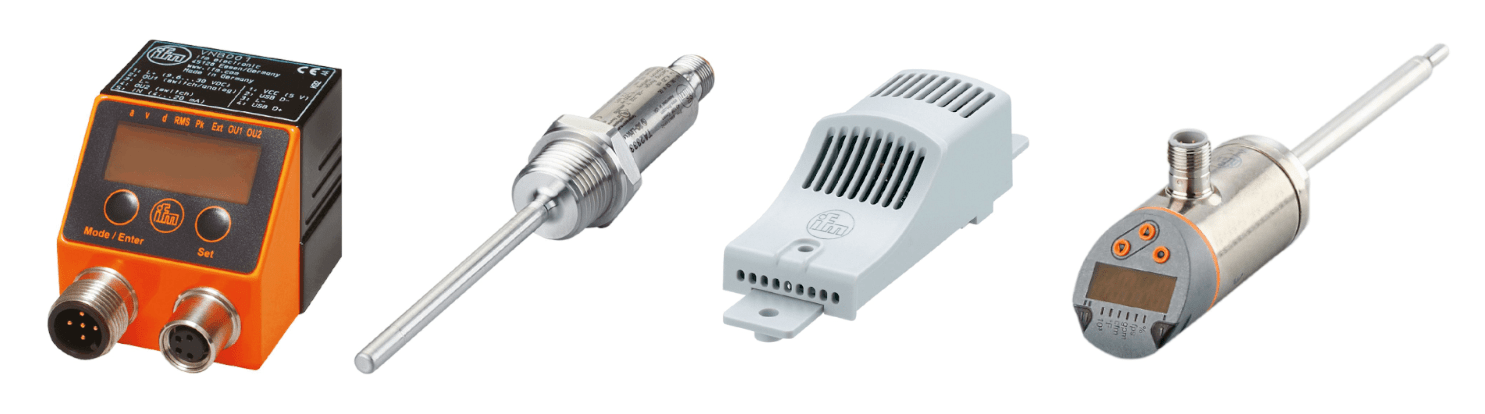

Appending Sensors

To build on the data captured natively from machine controls, MachineMetrics customers can use additional IIoT sensors. MachineMetrics' IO-Link connector in tandem with IO-Link sensors and an ifm master enables the capture of environmental variables that are not measured via the machine control - such as ambient temperature, humidity, and coolant temperature. There are 26,000 IO-Link sensors available from several different providers that MachineMetrics supports via an ifm master. This means you can track nearly any data point you can think of.

Examples of sensors from ifm.

Now, let’s dive into some of the data points that can be captured with MachineMetrics.

What Data Can I Capture with MachineMetrics?

Machine Data

Machine data is information concerning the machine's performance and health. These data points express the status of the run or machine. There are several categories of machine data:

- Quantity: Quantity is the measured physical properties of the machine, including strokes, cuts, movements, and other variables.

- Position: The position of a spindle or the path position of the spindles within a CNC machine can be measured.

- State: The state of a machine has many measurement points, including active, interrupted, ready, stopped, unavailable, and more. In complex machines with multiple execution paths, each point can be measured.

- Alarms: Alarms indicate machine condition and capture metrics such as pressure and load. They have subcategories for faults, warnings, availability, and other variables that alert operators to what is happening and where.

- Count: Counts are essential and should be measurable on any machine.

Operational Data

Raw machine data alone lacks certain context that makes it difficult to tie machine performance to the rest of the operation. With operational data layered on top of machine data, users can connect performance to particular operations, people, machines, and dates/times.

For example, users can capture accurate cycle times from a given operation which will create a benchmark for running that part in the future. Without context into what operation was running, this would not be possible.

Some of the operational data points MachineMetrics provides:

- Activity: The periods that work is being performed on equipment. This data ties into production schedules and sets up standards.

- ActivitySet (Production Runs): The data model used to measure the activity in the steps during a production run.

- ActivityType: This is broken into setup and production types. It can also be broken down into subcategories like teardown, tooling, etc.

- Annotation: Lets human information be added to machine data and conditions. This provides context to operations and enables better understanding upon analysis.

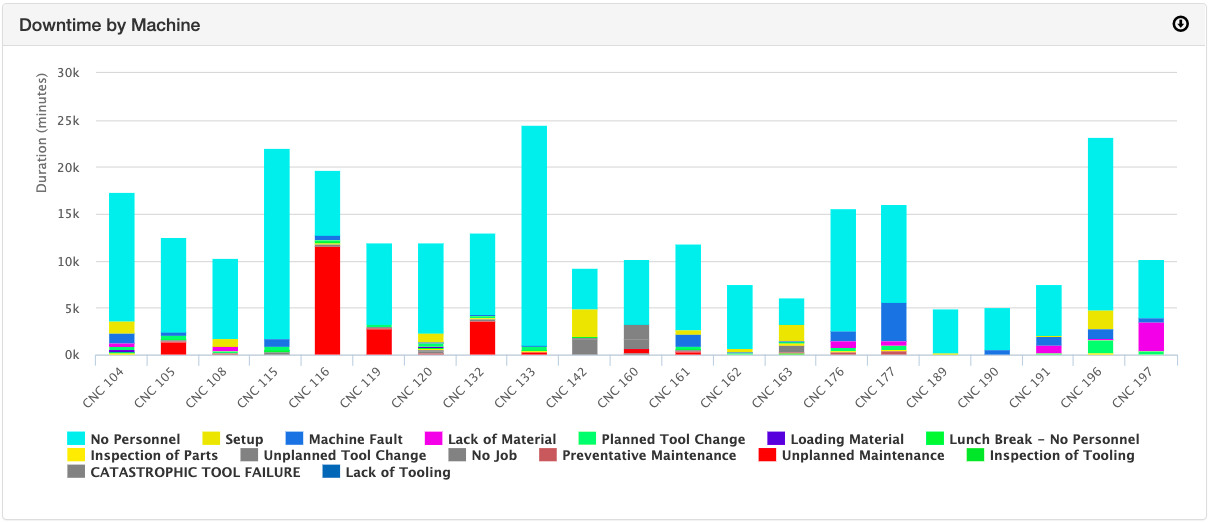

- AnnotationType: Enables the measurement of specific events, such as categorized downtime. Annotations can be customized to company needs.

- Company: Company data, including operators, machine numbers, and other data exclusive to the company for identification and evaluation purposes.

- Machine: The equipment or asset connected to the platform.

- Operation: The preset production standards applied to the job being run. Data will indicate whether the run is done according to these standards, and analytics can measure variances and provide insights for improvement.

- OperatorRun: The shift or period assigned to an operator running the machines.

- Operator: The person running a machine or set of machines.

- PartsCountCorrection: Data collected from the parts counter is matched with the PartsCountCorrection to ensure accuracy.

- Reject: Off-quality parts detected by sensors or other machine condition states.

- RejectReason: The reason for each rejection is categorized for analysis.

Putting Your Data to Work

MachineMetrics enables discrete manufacturers to finally extract valuable data from their production and operations. With accurate, real-time information from machines and operations, manufacturers not only have immediate production visibility, but key insights to take action on.

This typically helps users boost utilization by 20-40% in a matter of months while putting them on a roadmap to enabling even greater value creation. Take a look at some of the most common use cases you can enable, or set up a time with our team today to learn more.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments