Manufacturing has always relied on data to measure performance and identify areas of opportunity. But as technology has advanced, many manufacturers continue to operate as they have in the past.

The tradition of manually collecting production data has many inherent problems. With powerful monitoring and analytical capabilities now readily available, manual data collection is quickly giving way to automated solutions.

Manual vs. Automated Data Collection

1. Manual Data Collection

Manual data collection traditionally consisted of clipboards, pens, whiteboards, stopwatches, and timers. These were (and continue to be) used to record production figures, downtime events, and scrap rates. They were also used to measure labor and motion within the workplace.

As computer technology advanced, these tools were replaced by Excel spreadsheets and eventually some standalone computer software to provide better quality data and analysis. But the recording and measurements were still manual and prone to human error and bias. The data itself was delayed, inaccurate, and less actionable.

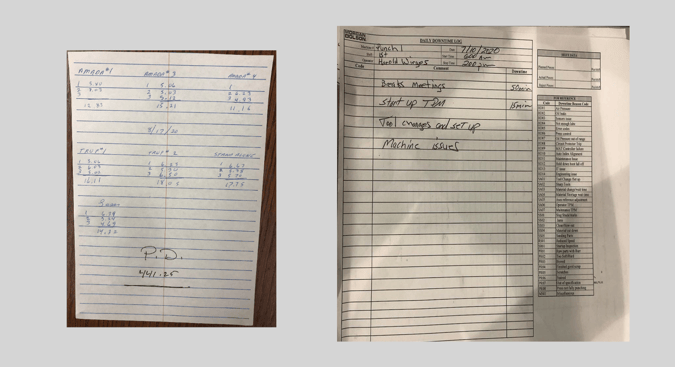

One of our customers recently shared some of the paper-based documents they used to fill out in order to track downtime events. They now automate this process with MachineMetrics. Read their full story here.

One of our customers recently shared some of the paper-based documents they used to fill out in order to track downtime events. They now automate this process with MachineMetrics. Read their full story here.

2. Automated Data Collection

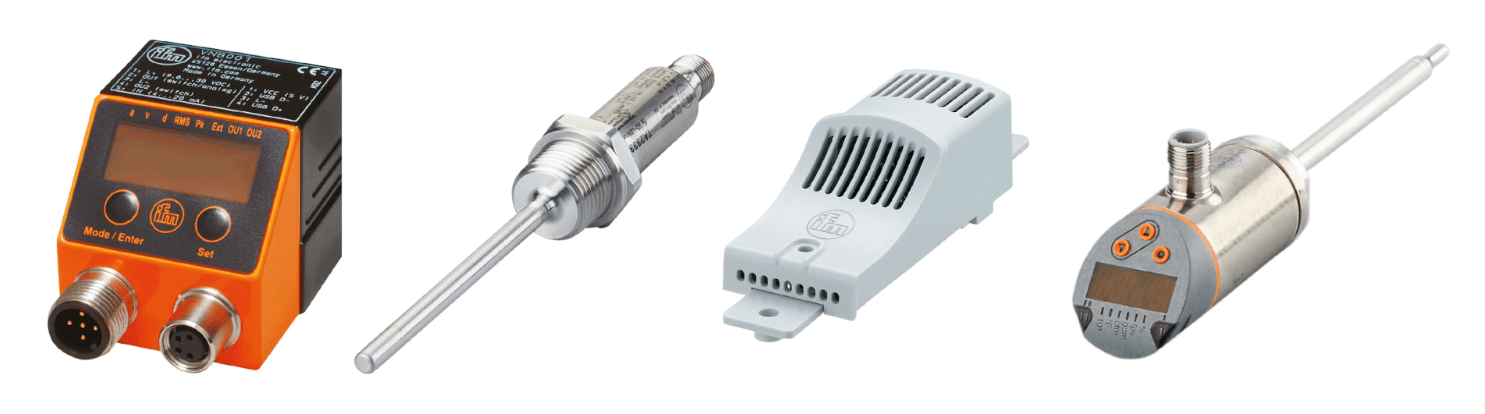

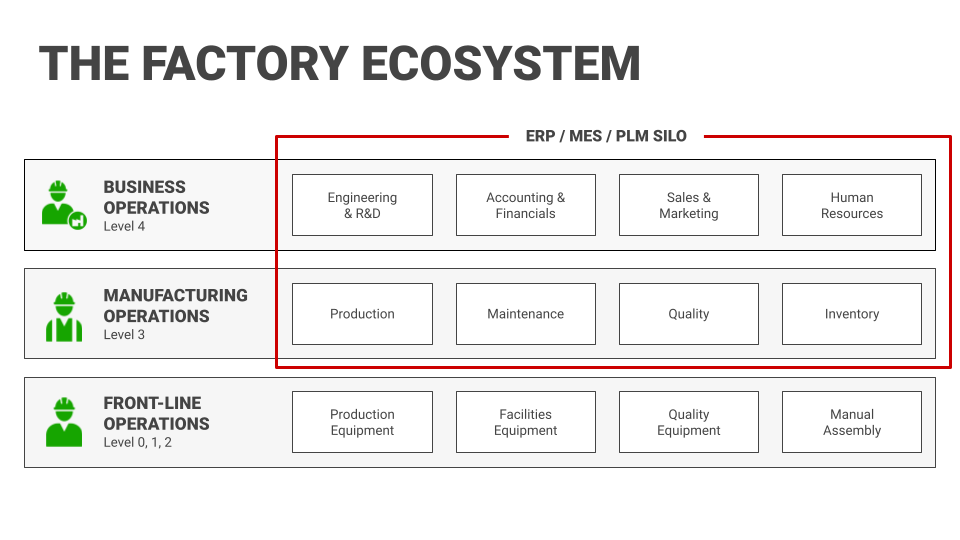

Automated data collection is part of the digital transformation of manufacturing. This concept involves collecting real-time data directly from the machine using devices and sensors. Over time, many OEM providers began adding automated data collection to their equipment.

While that improved data collection, it was still a fragmented process due to legacy systems requiring manual data entry and software that wasn’t connected to real-time data acquisition devices.

Today, manufacturers use machine data platforms to autonomously collect, standardize, and contextualize production data. This provides insights for better decision-making, greater efficiency, and the optimization of manufacturing processes.

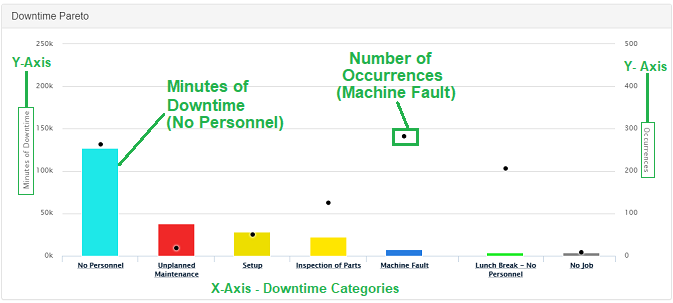

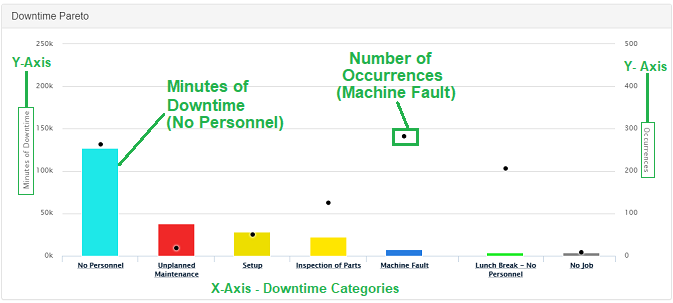

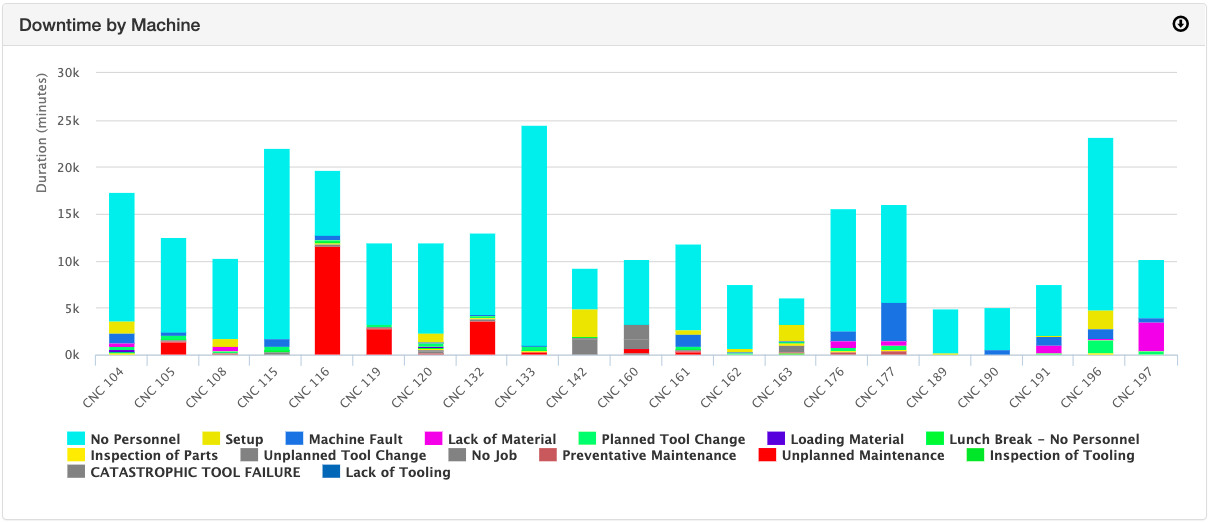

Automating data collection gives manufacturers immediate insight into production problems and opportunities, without all the effort of collecting, standardizing, and analyzing data. Above is an example of a downtime report from MachineMetrics.

Automating data collection gives manufacturers immediate insight into production problems and opportunities, without all the effort of collecting, standardizing, and analyzing data. Above is an example of a downtime report from MachineMetrics.

The Costs of Manual Machine Data Collection

Manual data collection may seem like a decent short-term approach, but it can be quite costly for manufacturers.

Not only are manual strategies highly inefficient, error-prone, subject to bias, time-consuming, and time-lagged, but they also make it difficult to get accurate real-time insights. You typically have to wait until the end of the day, week, or month to get a summary of data. This means you can’t make timely decisions that could improve your production process.

Manual data collection is also labor-intensive and takes resources away from the plant floor and diverts them to non-value-added tasks of sorting, organizing, and delivering manual data to the end-user. This not only impacts your current productivity but also prevents people from identifying opportunities and improving processes.

In fact, it works completely against the idea of continuous improvement because it not only takes away time from your employees but hinders innovation altogether.

As your business grows and you add more products, lines, and employees, manually collecting data becomes increasingly costly. We review this list of ever-growing consequences below.

Deploying MachineMetrics helped Avalign Technologies automate data collection, reduce downtime and increase OEE, resulting in millions of dollars in additional capacity. Read Avalign's story.

Want to See the Platform in Action?

Manual Data Collection Leads to Even Greater Problems

Manual data collection is a poor way to collect operational data. Processes that rely on paper and spreadsheets create many problems for performance measures, making them “gappy,” inaccurate, and often too out of date to be utilized effectively. It tends to be a problem that compounds upon itself.

Reduced Productivity

Each stroke of a pencil or mark on paper reduces productivity. The variables and factors that operators must write down continue to erode productivity significantly. Worse still, the more complex the data is, the greater the chances of human error.

This could mean a significant reduction in operating time on a per-minute basis. It also distracts operators from vital machine condition monitoring and other tasks which impact quality and machine health.

This problem extends into analysis, in which all of this data must be manually compiled, contextualized, and formatted into digestible reports and visualizations.

An operator interacts with a MachineMetrics tablet, enabling him to stay on track for expected production goals.

An operator interacts with a MachineMetrics tablet, enabling him to stay on track for expected production goals.

Badly Batched Metrics

Most operators and technicians realize the inherent problems with manual data collection. Because of this, employees create workarounds to improve the process, which may only make it worse. Instead of recording each occurrence as required, many operators will choose to record it in batches during a break or the end of a shift. This may stretch to include batch recording every several days rather than on a regular basis. As a result, the accuracy and reliability of the data are reduced.

Employee Resentment

Manual processes for data collection can trigger employee resentment. Since motion and work measurements are also manual, it’s not uncommon for recording time to be left out of time studies. Employees then face pressure to meet quotas, hit specific production rates, and achieve other goals set by the manufacturing business. In turn, they resent the time it takes to stop and mark their manual data because it pulls them away from essential machine functions.

Expired Information

Manual data requires compiling, sorting, data entry, human analysis, and more to provide insights for managers to use in decision-making. But, it’s sometimes relevant only to a particular day, shift, or hour. Commonly, manual data is too outdated to be useful by the time it’s finished being processed.

Further, the data is likely to be poorly managed, making it difficult to run historical reporting and analysis.

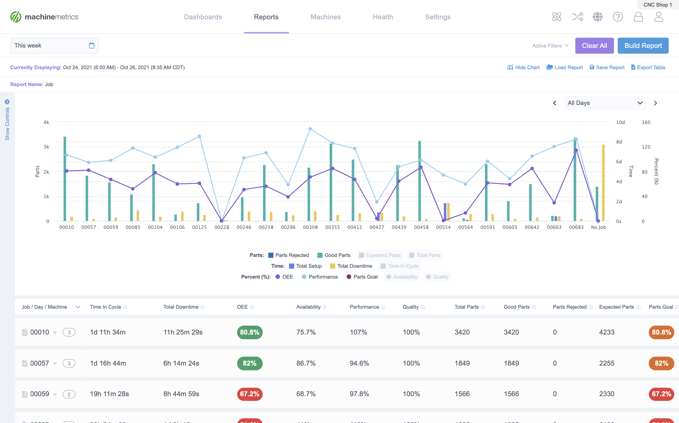

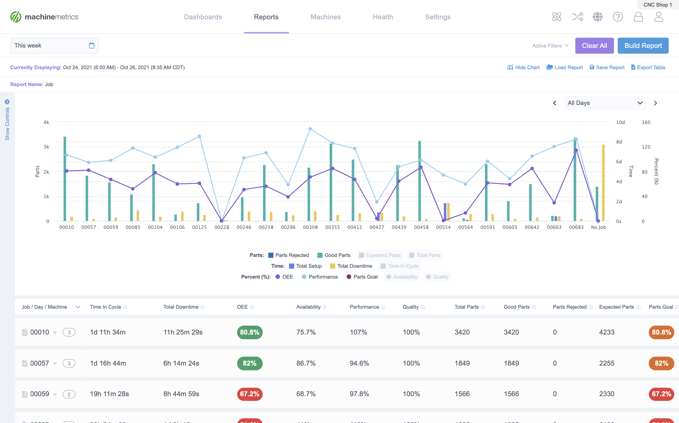

MachineMetrics can be used to run historical reports, as well as to dive deep into whichever layer you need insights from, including at the plant, process, machine, or operator level.

MachineMetrics can be used to run historical reports, as well as to dive deep into whichever layer you need insights from, including at the plant, process, machine, or operator level.

Poor Decision-Making

Reduced productivity, bad batch data, employee resentment, and expired information lead to poor decision-making. If a manager looks at production rates impacted by an operator who has lost much of their time recording data, they may decide that it drives up labor costs. Or they may determine a course of action based on expired data that has no real impact on the operation.

Unstructured Data and Lack of Trends

The data collected manually is often unstructured. This type of data makes it difficult to do anything but high-level analysis. That might be fine for some purposes, but it’s not enough to really understand what’s happening on the shop floor. You can't fix what you don't understand.

Without trends, there is no way to identify the root causes of problems. This is particularly important in lean manufacturing environments where small problems can quickly become big if they're not addressed immediately. This will make identifying root causes quite difficult.

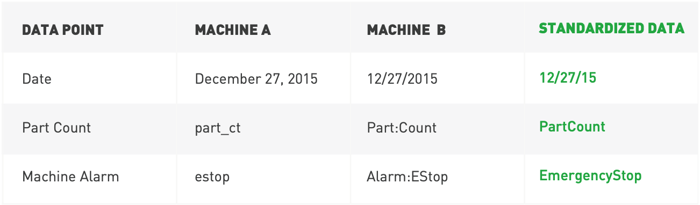

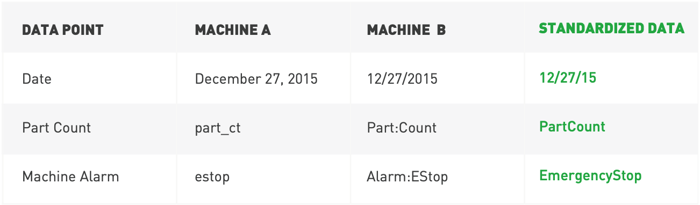

One of the pillars of MachineMetrics is the capability to connect to and collect data from any manufacturing equipment. This autonomous data collection and standardization ensures that data is immediately actionable. No need to compile and translate data into a common model. It is already available for consumption in pre-built reports and dashboards.

Limited Scope

Manual data collection cannot usually “zoom” in and out at the spindle level to the machine level to the factory floor or shop floor level. It may also lack the ability to classify machines by product or type. As a result, team members spend more time trying to find the data they need, find out what’s actually happening on the shop floor, and make accurate decisions. This also makes it difficult to find and fix issues with specific machines.

Human Error

The most glaring issue with manual data collection is human error. This may be simple lapses such as transposed numbers, handwriting problems, or forgetting to record data. It may also mean more complex errors like differences in interpretation between operators on different shifts or recording the same information in multiple formats.

Incorrect Root Cause

Root cause analysis is vital in any manufacturing business. It’s especially important for lean manufacturing and those that rely on continuous improvement. With the combination of human error, time-consuming non-value-added tasks, and other problems associated with manual data collection, it may be challenging to determine a root cause.

Suppose a root cause is identified based on a time study that doesn’t include operator recording time or one that relies on outdated manufacturing information. In that case, the wrong root cause decision can make things even worse.

Operator Inattention

If an operator is recording a stop or an event, their attention is diverted from running the machine. This can cause additional downtime if another stop occurs while recording the first. Even worse, this lack of attention can lead to dangerous safety conditions because the operator isn’t focused on the machine.

Operators and Managers can use MachineMetrics as a "toolbox" to make better, faster decisions on a daily basis. Further, they can build custom historical reports and use real-time machine data to enable automation.

Incorrect Data

Human error may lower the quality of data collected at the machine level. But, that incorrect data passed from department to department or entered into an ERP system can result in the wrong decisions being made within the enterprise. Incorrect data impacts purchasing, inventory accuracy, scheduling, and ultimately, delivery. When data isn’t reliable and accurate, it can impact competitiveness and drive up costs.

Manual Strategies Give Way to Automated Solutions

The problems associated with manual data collection run counter to what the manufacturing industry has learned in the decades since the first industrial revolution. OEM companies are already including embedded automated data collection capabilities in new equipment.

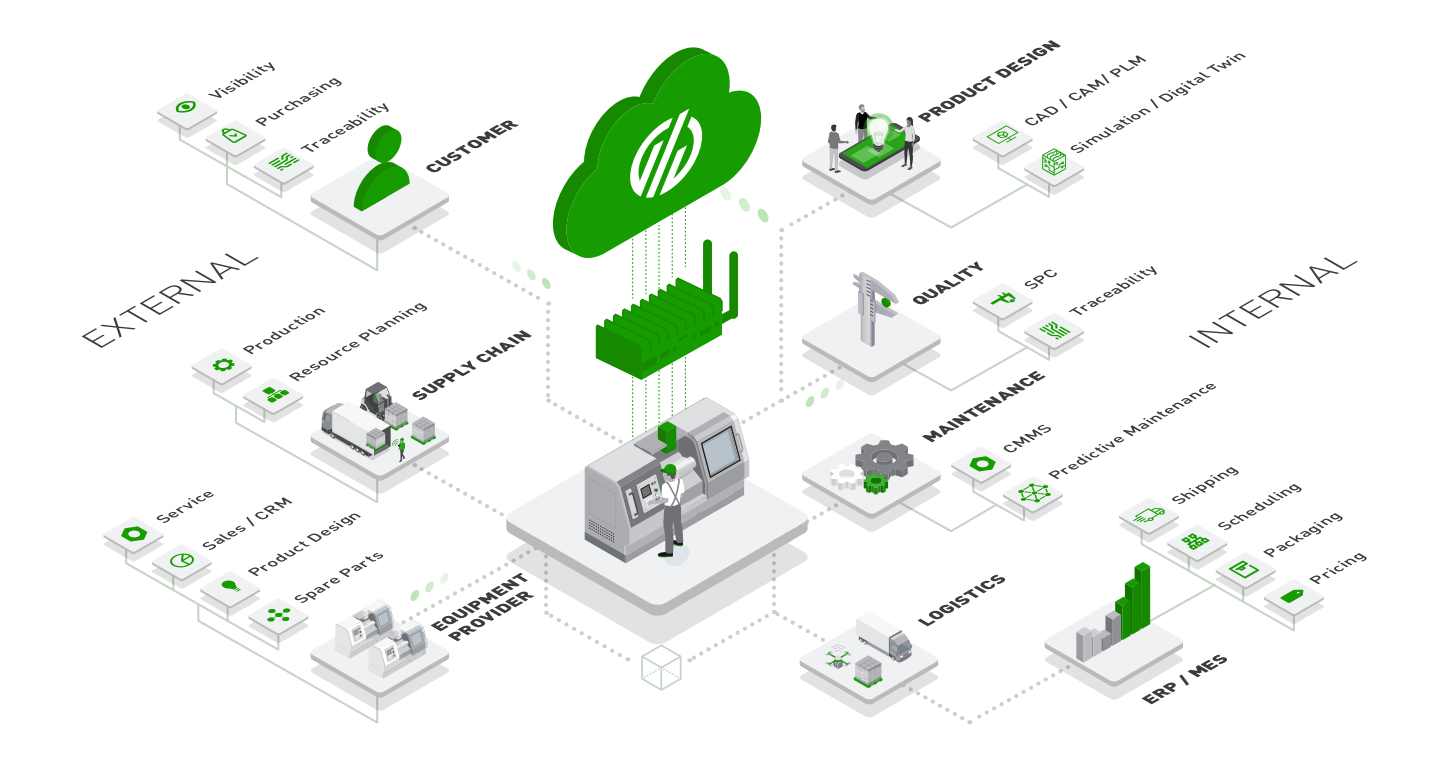

This functionality works with MachineMetrics Machine Data Platform to collect machine performance and conditions directly from the machine.

Plug-and-play Machine Connectivity

Legacy systems such as analog equipment can also be added to the connected ecosystem to allow complete production monitoring across all machines within a company.

The writing is on the wall for manual data collection. As businesses seek to improve their market share and competitive edge, manual data collection won’t survive.

Your Competitors Are Rolling Out Digital Solutions. Are You?

Data must be relevant, accurate, timely, accessible, interoperable, and transparent. Manual data collection isn’t capable of any of these requirements, much less all of them.

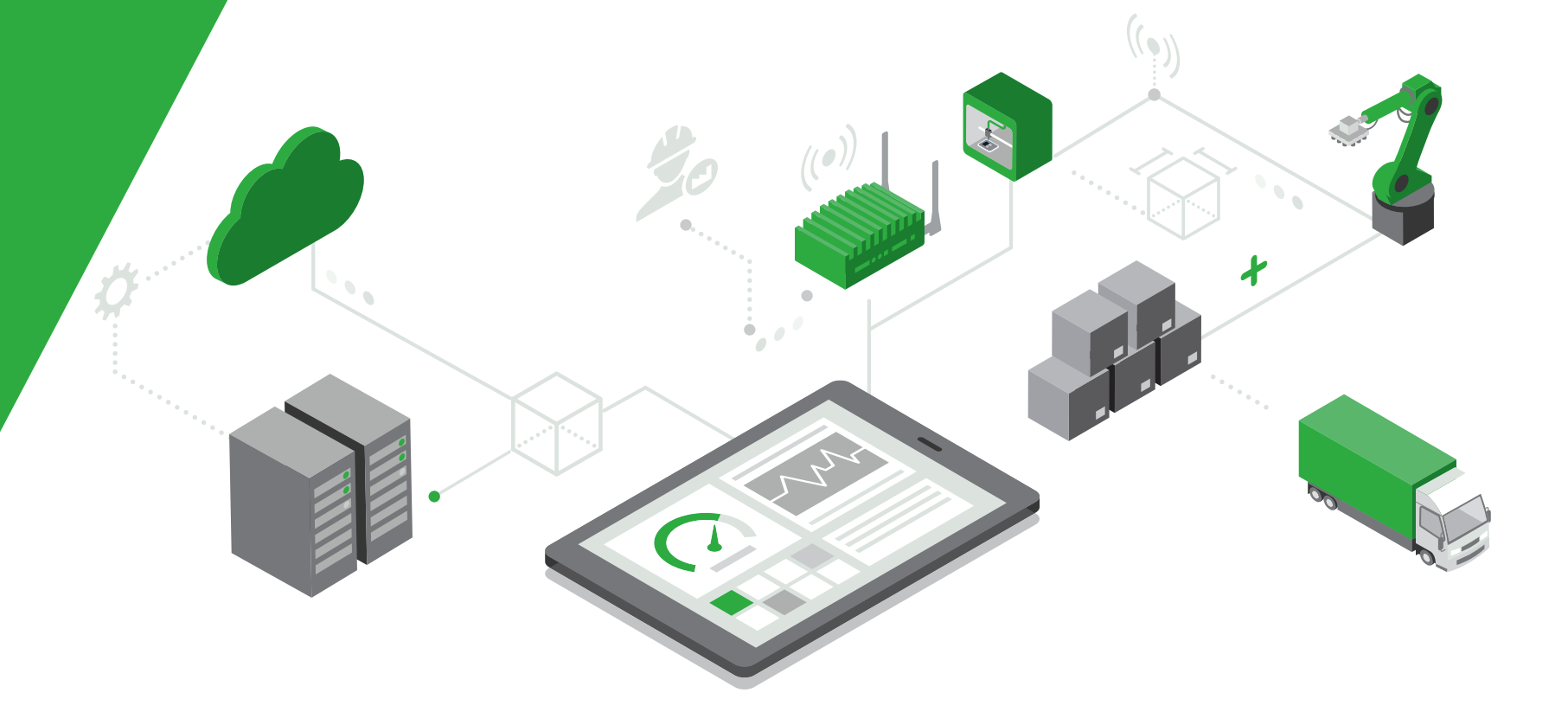

Automated manufacturing technology will make manual data collection obsolete. Digital solutions can eliminate manual collection and allow operators, technicians, and managers to optimize processes and increase efficiency.

This is done by utilizing best-in-class platforms that can enable connectivity across all equipment. These solutions collect, organize, structure, and analyze data based on business needs and return it to users with real-time insights.

Automated manufacturing technology eliminates all the problems inherent to manual data collection. Staff is no longer needed to collect, sort, enter and analyze data, so labor is no longer required for non-value-added processing.

Real-time shop floor dashboards provide accessibility to all stakeholders on the shop floor, enabling people to make better, faster decisions on a daily basis.

Real-time shop floor dashboards provide accessibility to all stakeholders on the shop floor, enabling people to make better, faster decisions on a daily basis.

Unlocking the Power of Real-Time Data with MachineMetrics

MachineMetrics understands that accurate, timely data is the key to great production processes. Manual data collection can be eliminated with the MachineMetrics Machine Data platform, providing clean, accurate data and real-time analytical insights.

The results will help you optimize processes, increase productivity, and improve operations. In fact, our average user sees a 20% increase in efficiency. Interested to see how it works for yourself? Book a demo today to learn how we can help you accelerate your digital transformation and eliminate the need for clipboards, pens, and spreadsheets.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments