Why is Manufacturing Efficiency Important?

Improving manufacturing efficiency is a key tenet of the industry. Leveraging lean strategies to drive down the costs of production while retaining quality and increasing throughput is a constant challenge. However, with a mindset of continuous improvement, manufacturers see this more as an opportunity than a problem.

After all, manufacturers can only be so efficient, and as long as they are beating out competitors, they are winning. However, as new technology emerges that allows them to use data to make better, faster decisions, there will be a rising tide of what is accepted as “standard” within the industry. For example, despite the number of workers employed in manufacturing declining, output has grown.

Productivity vs. Efficiency in Manufacturing: Here’s The Difference And Why It Matters

Productivity and production are not synonymous, contrary to popular usage. While they are both worthy paths of optimization, manufacturers should understand each concept and the relationship between them in order to guide these improvements.

Productivity is a Measure of Efficiency, but Not Vice Versa

Product, production, efficiency—all words you’ll hear many times a week in any manufacturing facility, all with the same root. This is the easiest way to remember the meaning of productivity.

“Productivity is commonly defined as a ratio between the volume of output and the volume of inputs. In other words, it measures how efficiently production inputs, such as labor and capital, are being used in an economy to produce a given level of output. Broadly, productivity measures can be classified as single factor productivity measures (relating a measure of output to a single measure of input, e.g. labor productivity) or multifactor productivity measures (relating a measure of output to a bundle of inputs, e.g. multifactor productivity). Productivity is considered a key source of economic growth and competitiveness.” – OECM Library

In simpler terms, productivity is the measure of how much you produce compared to how much of whatever resource it took to produce it.

Efficiency is Broader than Productivity

Efficiency in manufacturing takes into consideration more than simple input and output by the numbers. Efficiency in manufacturing includes things like quality and effectiveness of work and can suffer when productivity is overly-prioritized.

Instead, setting production efficiency goals helps manufacturers focus on the bigger picture and do work correctly, not just productively. Focusing on machine efficiency in manufacturing means utilizing resources as optimally as possible, maintaining a high quality of work, minimizing risk, and reducing potential losses.

That is not to say productivity should be neglected for the sake of efficiency. If you can’t meet demand, then you still have angry customers (or would-be customers), and unless you’re intentionally using scarcity tactics to your advantage, you lose out on a lot of potential business and related revenue.

Five Stages for Improving Manufacturing Cycle Efficiency

Manufacturing cycle efficiency begins far before a widget is produced, and continues after production as well.

It’s important for companies to take into consideration all elements of this timeline in order to provide a product that ensures a competitive cycle time.

Each element of the product lifecycle — from innovation, design, and development to testing and, eventually, manufacturing — must be examined in order to remove waste from the overall process.

Below is a shortened version of the full article on improving cycle efficiency.

Concept and Development

Developing new products often leads to a fair amount of waste simply because efficiency is not wrapped into the process.

Ordering Process

Without a streamlined ordering process to account for possible complicating factors, like the currently held amount of stock, volume of sales, or future trends., manufacturing cycle efficiency can be easily hindered.

Production Scheduling

Production should be scheduled in such a way that maximizes a company’s manufacturing facilities, including both available equipment and labor.

Manufacturing

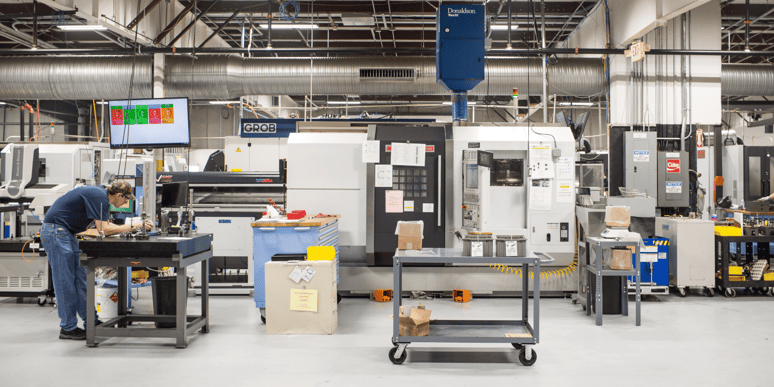

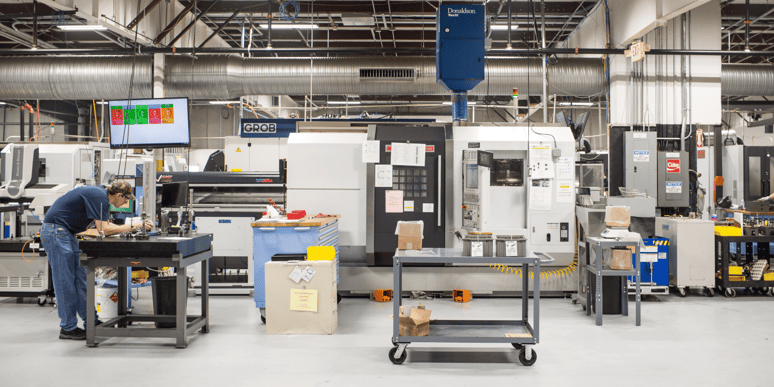

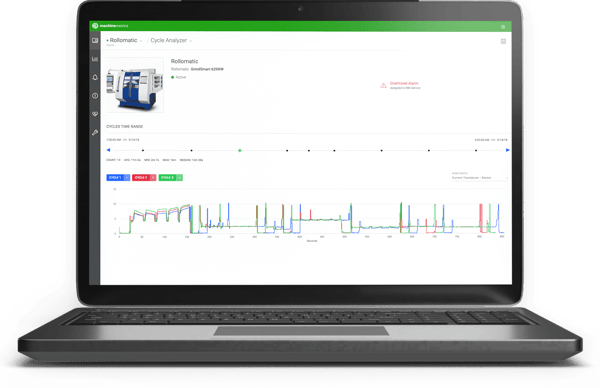

To become leaner and eliminate waste, savvy companies employ machine monitoring software to get real-time visibility into shop floor performance.

Transportation

Cancellations and payment delays, among many other problems, are just two outcomes that can undermine all your efforts at manufacturing cycle efficiency.

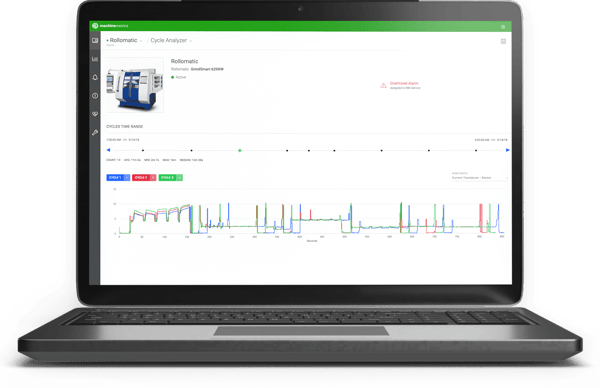

A dashboard from MachineMetrics that analyzes cycles.

A dashboard from MachineMetrics that analyzes cycles.

How to Improve Manufacturing Efficiency

Manufacturing efficiency can be improved in the following ways:

Identify Bottlenecks

Bottlenecks can quickly stop a production line, which can starve downstream processes and frustrate staff. The most significant impacts are on the efficiency of the production line and the entire shop floor.

You can identify bottlenecks and improve process efficiency by conducting a bottleneck analysis. This type of root cause analysis helps identify places in the manufacturing process where workflows are constrained.

Once constrained process areas have been pinpointed, solutions can be implemented to clear the bottleneck. These solutions are generally used to update the optimization process and prevent future constraints.

Reduce Waste

Reducing production waste is a common theme among manufacturers, although many overlook it as a method to improve production efficiency. Start with the obvious: recycle, rework, or remove material. This creates space that would otherwise impede WIP and material staging needed for production.

However, waste is more than just scraps and trash. Adopting a Lean manufacturing philosophy to extend the definition of waste to include waiting, unnecessary motion, and other constraints will help you identify additional waste in the production process.

Utilize Standard Work

Standard work is one of the most valuable tools to reduce manufacturing process variation and improve production efficiency. Each person works differently if left to their own choices. By posting detailed standard work instructions with pictures and graphs, all employees are prompted to perform tasks the same way. Automated standard work is ideal, enabling real-time changes and updates.

Get Organized

Housekeeping is a much more significant contributor to low machine efficiency in manufacturing than many realize. It impacts material flow and quality in the form of contamination. It also creates confusion when employees can’t find the necessary tool, affecting morale.

One beneficial Lean manufacturing method is implementing a 5S program. Quick and easy to follow, a 5S program of sort, set in order, shine, standardize, and sustain ensures that all workstations have what they need when they need it.

Audit Your Processes

Many manufacturing processes are built with unnecessary steps. Others may have veered over time as a new machine or plant layout was implemented. Auditing processes and workflows by process mapping will help identify trouble spots and enable process improvement.

Process mapping can be done for a specific product or machine, or it can be done for the entire facility. Training employees on any new steps and performing regular audits will help ensure increased manufacturing efficiency.

Train Employees Regularly

Many manufacturers train employees once and rarely revisit that training. In modern manufacturing with advanced automation, training should be regular and ongoing. Regular training helps keep existing processes on track and ensures employees are trained on new processes promptly.

Implement Cellular Manufacturing

If your facility has many similar processes, consider adding cellular manufacturing to improve efficiency. A cell may have machines that perform multiple tasks, but its output and contribution to the factory floor and process flow are considered a single set of standard tasks. Material, supplies, and tools can be staged and set for use by the cell to reduce unnecessary steps.

Improve Maintenance

Preventive maintenance has been the norm for many decades in manufacturing. But whether your maintenance is preventive or predictive, it needs to be optimized to reduce equipment failures as much as possible.

An optimized maintenance strategy's power is multiplied when CMMS systems and other software are used to plan and organize maintenance tasks. Machines will reach optimal performance as overall equipment effectiveness rises across the factory floor.

Automate

Most manufacturing operations have some degree of automation, as OEM equipment companies often add it to their lines. But automation is more than just machine functionality; it also includes process and task automation.

This automation is incredibly impactful when manual, time-consuming, and error-prone tasks (such as data collection) are moved to automatic collection and real-time relevance. When this automation is accompanied by the advanced analytics of a machine data platform, it can supercharge machine efficiency in manufacturing.

Use Real-Time Data

The best way to optimize processes for maximum efficiency is by leveraging your machine data. A machine data platform provides real-time insights and drives opportunities to utilize smart manufacturing across many functions. All of these functions boost efficiency and improve business processes.

How to Calculate Manufacturing Efficiency Using Manufacturing Efficiency Metrics

Measuring and analyzing your successes, failures, and progress is critical to success in the manufacturing world.

Manufacturing efficiency metrics can be calculated using different sets of numbers relevant to efficiency, but the overall concept remains the same. In order to find your manufacturing efficiency, use the manufacturing efficiency formula and divide your standard output by your actual output, then express this number in percentage form. There is software that can do this for you automatically, or you can calculate the manufacturing efficiency formula manually.

Calculate Your Actual Output

Of course, this first requires you to define your outputs. To determine your actual output, divide your total output by your total input. How you express this will depend on which unit you choose to measure productivity in to determine your manufacturing efficiency metrics.

We’ll use an overly simplified example:

- You can create 50 widgets for the cost of $100

- As a result, each widget costs $2.

- Input: $100 Worth of Costs

- Output: 50 Widgets

- Actual Output: $100 of Costs / 50 Widgets = $2 per Widget

Calculate Your Standard Output

Standard output can be something you pull from your own historical data or from an industry benchmark which you might find in a report. In this way, you can measure yourself against your past performance, a competitor, or the industry as a whole.

Combined, these two numbers can give you your efficiency in manufacturing which can be used to set KPIs in conjunction with other measures of efficiency.

Continuing with the example above, let’s say a competitor, who you would like to compare yourself against, is able to produce 55 widgets at a cost of $100.

- Competitor’s Actual Output: $100 of Costs / 55 Widgets = $1.82 per Widget

- Your Standard Output = $2 per Widget / $1.82 Per Widget = 1.0989

1.0989 suggests that it costs you roughly ten percent (9.98%) more to produce a widget than it does for your competitor. Based on these metrics, you are approximately 10% less efficient than the competitor you are measuring against.

Taking Your Operation to the Next Level with Data

There are a myriad of ways to measure productivity and efficiency in manufacturing, all with the intention of understanding production performance in relation to the profitability of the organization. At the end of the day, stakeholders at every level of the company, from operators to managers to supervisors to corporate, must have a strong understanding of how the shop floor is performing. And this is only possible when the team has complete visibility into accurate, real-time production data and reports in order to make better, faster decisions.

MachineMetrics helps manufacturers easily collect and use production data to boost both productivity and efficiency. Our plug-and-play solution gives operators and managers the tools they need to act fast, giving them instant visibility and control of the shop floor. In fact, customers see ROI in as few as five days as MachineMetrics can easily highlight major production bottlenecks. Interested in learning how we can help? Set up a demo with out team today.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments