The manufacturing industry is undergoing an enormous digital transformation. To assist solution providers in developing software and hardware that are compatible across a multitude of components, the International Society for Automation (ISA) established the ISA-95 framework.

The ISA-95 framework provides standards for integrating enterprise and control systems, making it easier for manufacturers who use these providers’ systems, hardware, and software to manage operations and streamline processes.

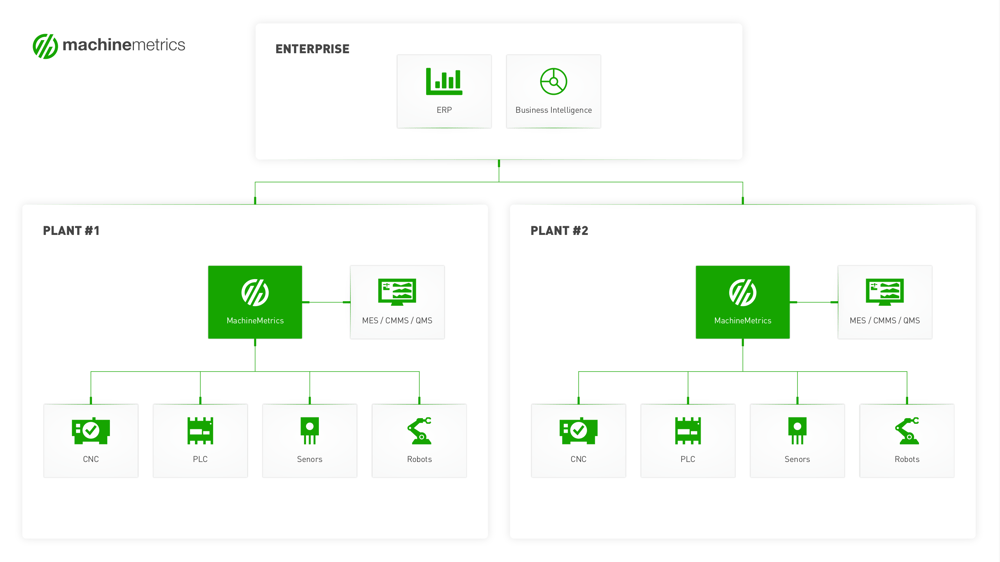

By using an advanced machine monitoring platform that enables shop floor data accessibility across the levels of the hierarchy-based ISA-95 framework, companies can bridge the gap between IT and OT.

What is ISA-95?

The ISA-95 framework, also known as ANSI/ISA-95, is a standard developed by the International Society of Automation (ISA) for integrating enterprise and control systems. It provides guidelines for communication between IT and OT systems. It also coordinates the management of all enterprise components so manufacturers can streamline processes, optimize supply chains, reduce costs, and better allocate resources.

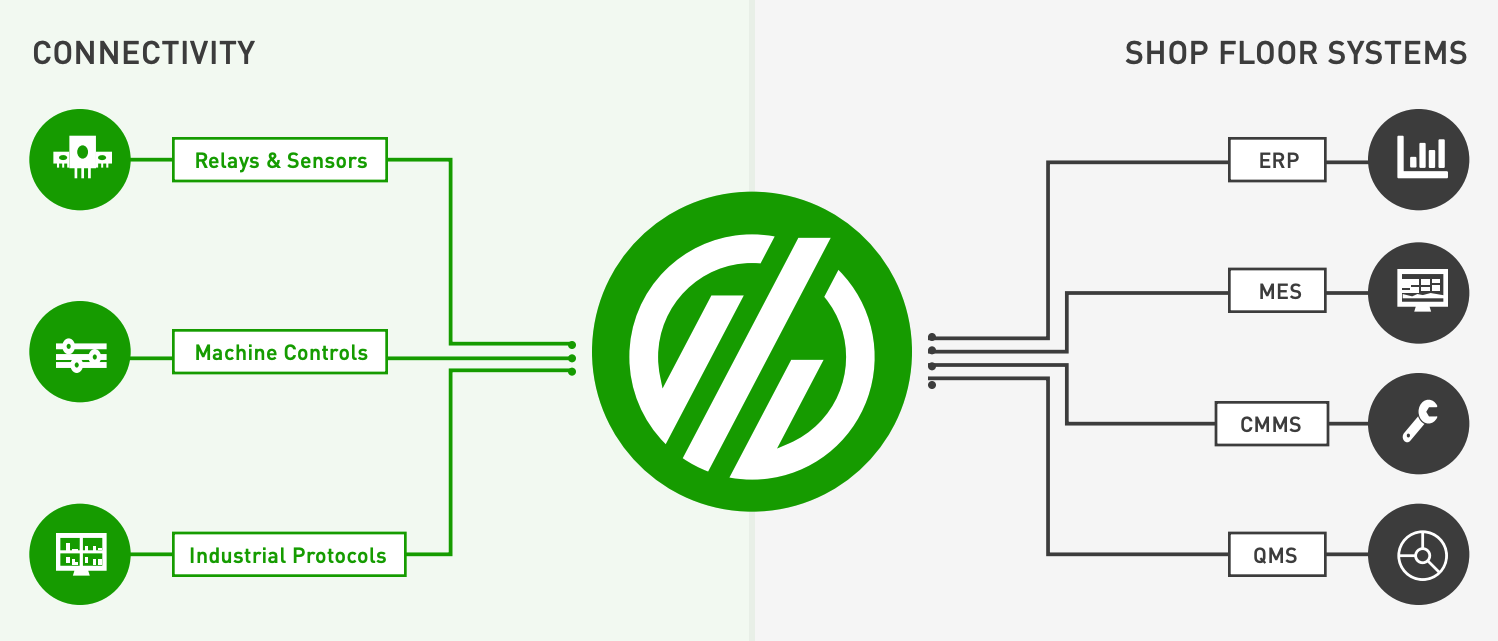

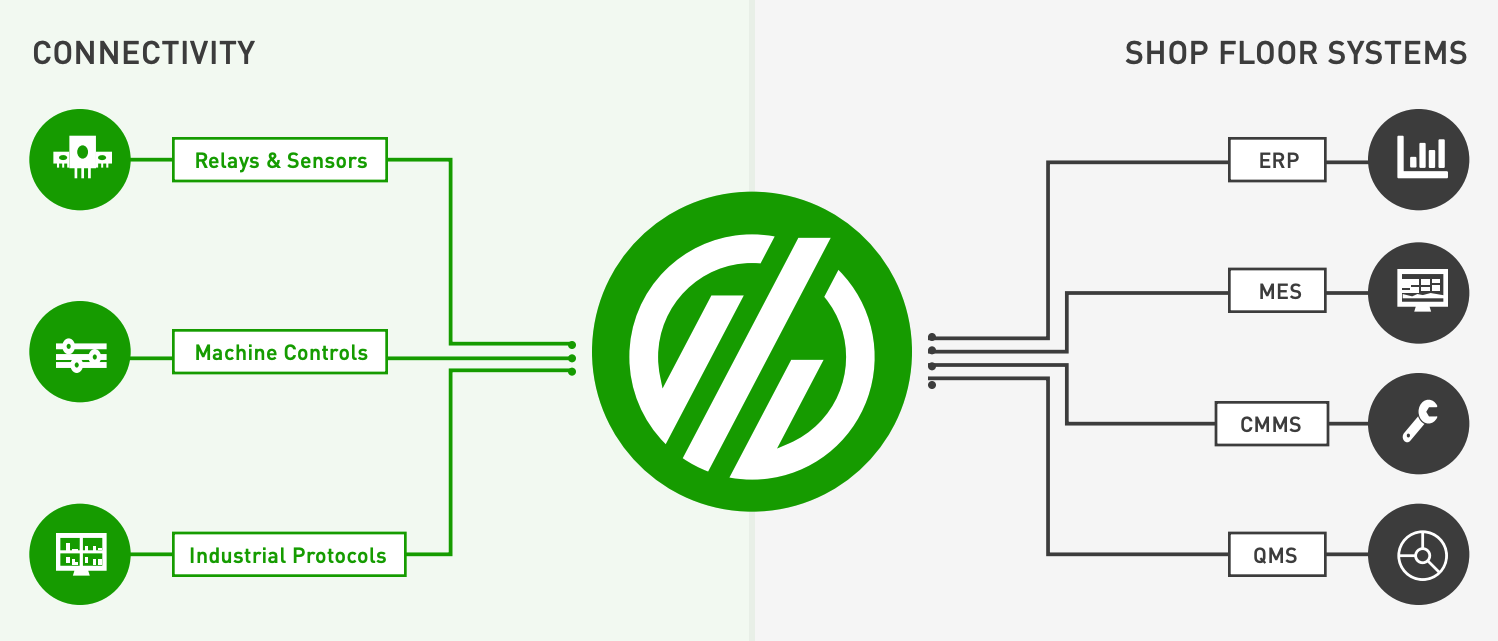

The framework establishes a clear interface that connects enterprise systems such as Enterprise Resource Planning (ERP), Computerized Maintenance Management Systems (CMMS), and Manufacturing Execution Systems (MES) to plant floor systems using Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA).

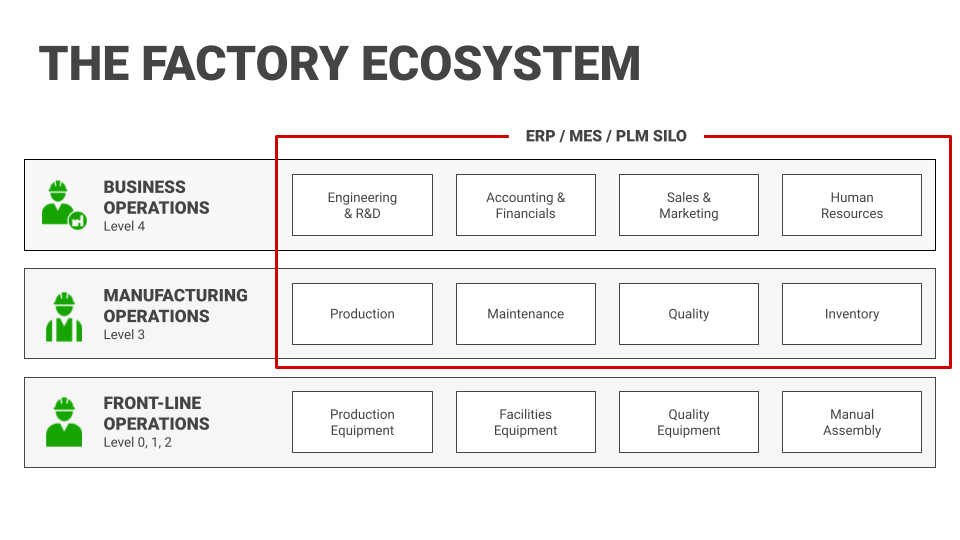

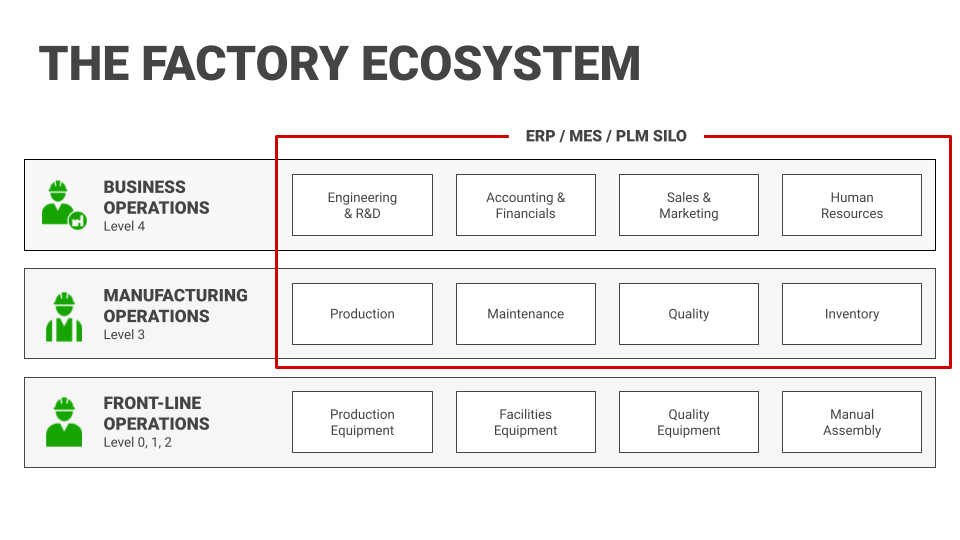

It also defines a hierarchical model for manufacturing operations management, which is divided into five levels:

- The Physical Production Level: This is the point of creation of each data point.

- The Sensing and Manipulation Level: This level consists of connectivity in the form of sensors, temperature or pressure monitors, counters, etc.

- The Control Level: Data at this level is still a bit raw but can be controlled and used within systems like SCADA.

- The Supervisory Level: At this level, systems like MES and CMMS can optimize processes, scheduling, capacity management, and more.

- The Enterprise Level: This is the level where enterprise decisions are made using ERP, MRP, and other business intelligence software.

This hierarchical model helps manufacturers understand the relationships between different systems and how they can be integrated to improve operations.

How Data is Flattened Within the ISA-95 Framework

While the framework is a helpful guide for building applications and systems, it still does not address many of the data challenges that operations have. For example, production data from the shop floor generally does not make its way into the upper levels of this hierarchy. Some of the data might make its way into an ERP, but generally it is delayed, inaccurate, and has costly commissions that inhibit decision-making.

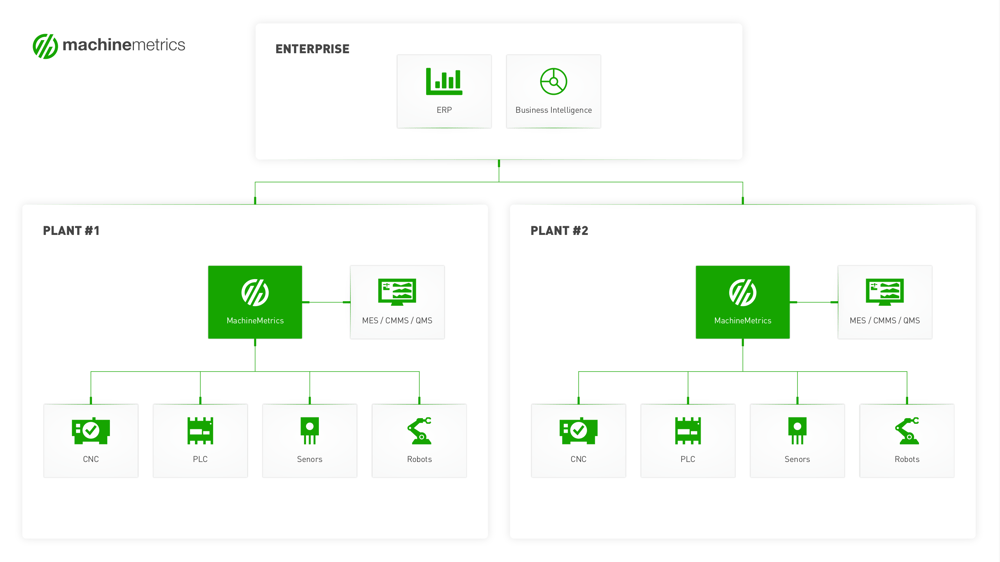

Manufacturers should not feel beholden to the template provided by ISA, at least not for the purposes of capturing and using data across the organization. For example, machine data doesn’t have to move exclusively along the established hierarchy. Instead, an extensible production monitoring platform with API integration can bring the data directly from the shop floor into your ERP.

With MachineMetrics the ERP has accurate data directly from production processes, flattening the framework and making data transfer, exchange, and action more efficient. This gives management and executives the data they need to make better decisions. It also aligns the business performance to shop floor performance to truly understand the effects of shop floor improvements.

Advantages of a Standardized Structure

In conjunction with an advanced machine data platform like MachineMetrics, the ISA-95 framework is an abstract model that provides guidance for making shop floor data accessible across the operation. MachineMetrics provides real-time monitoring and analytics for machines and production, allowing manufacturers to optimize their operations and reduce downtime.

One of the most significant benefits of this convergence is the ability to bridge the IT/OT gaps many manufacturers face. IT and OT have traditionally been considered separate domains in manufacturing, with different systems, technologies, and cultures. This gap made it difficult for manufacturers to integrate their operations and leverage data across their organizations.

While the ISA-95 framework provides a starting place for developing a unified view of operations, it must be utilized with a machine data platform to fully bridge the gaps between IT and OT and deliver a single version of the truth.

Otherwise, manufacturing management will be reliant on weak data for making decisions and automating systems.

Further Standardization for Manufacturers to Consider

Another idea that plays into this topic is the concept of a unified namespace, a standardized approach to naming and organizing data across different systems and platforms. It allows manufacturers to create a common language for their data, making it easier to integrate and analyze.

A unified namespace helps define an automation/IIoT standard framework, best practices, and guidelines. By creating a common language and approach to integrating systems and data, manufacturers can reduce the time and cost required to manage their operations. A standardized approach also helps providers like MachineMetrics build even more out-of-the-box solutions to reduce the time and training required for companies moving quickly and deeply into automation.

Moving Forward

A company’s tech stack, data strategy, and solution provider are critical to leveraging machine data. Integrating existing software to work across machine connectivity in production is also critical. This includes vertical solutions like quality management, quoting systems, and CMMS systems.

MachineMetrics uses machine connectivity and advanced analytics to create a data ecosystem that connects IT and OT under one data scheme, unlocking powerful and actionable insights to transform manufacturing.

History has shown the power of standardization and the dangers of competing ecosystems that aren’t interoperable. With the flexibility of MachineMetrics, there is still room to develop automation strategies and converge ISA-95 to improve overall operational performance and truly impact the bottom line from the shop floor up.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments