This article is part of a series discussing the value of machine data for shop floor management systems. Integrating machine assets into your connected factory ecosystem unlocks accurate, real-time production data that can be used to enhance not only production, but many other functions across both the shop floor and in business operations, from maintenance and quality, to quoting and planning.

How Do You Know When a Machine Needs Maintenance?

For discrete manufacturers, machines are the lifeblood of production. If equipment is maintained properly, then efficient production, lower costs, on-time delivery, and increased customer satisfaction can all be achieved.

Companies have continued to rely on broad averages and expectations to develop maintenance calendars. For example, maintaining equipment every 30 days or every 100 parts based on historical averages (or based on OEM recommendations).

Complexities such as equipment utilization, part failures, tool wear, vibration, and other equipment conditions have not historically been taken into account when deploying maintenance.

With a connected operation, there’s a way to ensure equipment performance and health data influence maintenance activity. This ensures that maintenance activities only take place when necessary, reducing the likelihood of costly over-maintenance, while ensuring equipment failures are avoided.

How? By capturing real-time and historical machine data to enable a more effective maintenance program.

By autonomously capturing, standardizing, and contextualizing machine data in real-time, maintenance programs can be designed to maintain equipment optimally. Below, we explore how MachineMetrics, a machine data platform, can add significant value to your Computerized Maintenance Management System (CMMS), and maintenance program overall.

How Machine Data Optimizes Maintenance

The value of Computerized Maintenance Management Systems is significantly enhanced by the volume and quality of the collected data from machines. Historically, this has been done by maintenance technicians manually monitoring equipment, documenting failures, and executing maintenance work orders.

The problem is that manually collected data is not only an incredibly wasteful use of time for operators and maintenance teams but results in delayed, inaccurate data that is difficult to take action on.

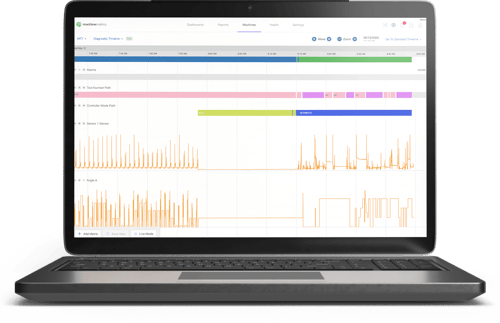

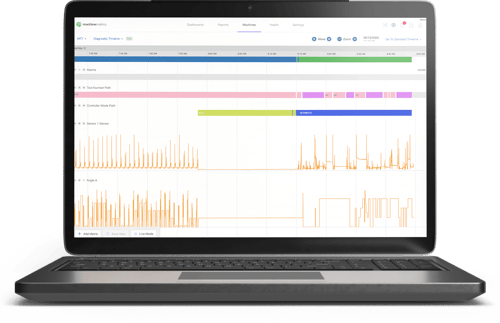

Enter MachineMetrics, a platform to autonomously collect machine data, standardize it across all makes and models of equipment, add context to it, and deliver it immediately to frontline users via notification and visualizations, or into management systems, such as a CMMS.

Now, real-time, accurate data on machine performance and conditions can be used to efficiently deploy maintenance, or even develop models to predict when failures will occur.

Let’s explore the value of machine data for your maintenance program:

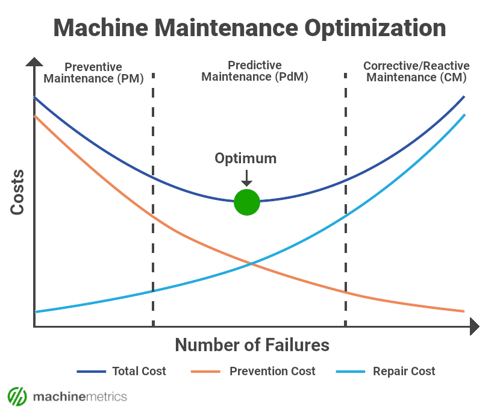

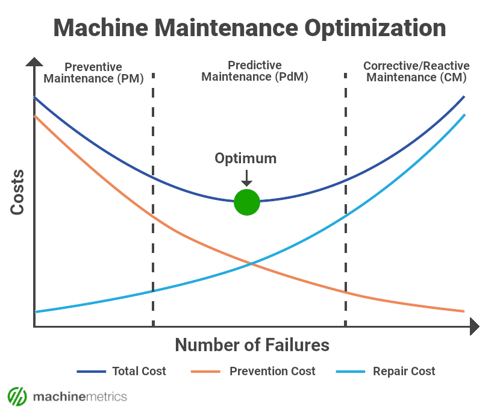

Transforming Maintenance Strategies

When machine data is processed using the MachineMetrics platform, it generates insights that allow the CMMS to achieve optimal performance. Maintenance schedules can then be based on real-time data and actual wear and conditions of the machine.

This means that strategies for machine health can be designed to be proactive and predictive rather than calendar-based or reactive. This machine health data also includes diagnostic data and insights that allow managers and technicians to respond before a part fails. This reduces downtime and eliminates the risk of greater damage to the machine.

- Old School: Reactive/Corrective or Calendar Based

- New School: Proactive or Condition-Based

- Future School: Predictive or Prescriptive

Resource Management

Maintenance managers are aware of the many variables associated with overseeing their program, from their internal staff, to the amount of labor and shifts required, to parts and fluids necessary to perform routine maintenance, to the quality and lifetime of the equipment.

Luckily, they have CMMS systems in place to help manage all these pieces, ensuring that the resources at their disposal can be used as effectively as possible. But, they are often relying on manually collected maintenance logs and OEM suggestions to run the program, rather than actual production data. By pushing machine data into a CMMS, better decisions can be made

What data can be used in the CMMS? Jobs, downtime events, part counts, OEE, machine diagnostics, environmental conditions, etc.

How does this help CMMS and maintenance managers to allocate resources effectively?

- Develop a better understanding of the staff necessary to support the facility

- Build schedules that support expected maintenance

- Predict the costs associated with routine maintenance such as part and fluids costs

- Manage the lifecycle of equipment to justify capital investment

Work Order Management

Maintenance teams can immediately move from a calendar-based approach to condition-based maintenance with machine data.

MachineMetrics workflows allow companies to look at their overall maintenance holistically. This means having a full view of conditions and health to make the right decisions with the use of insights.

Below are a few of the key features that directly impact how maintenance is executed, and how MachineMetrics can be used in tandem with a CMMS, or as a standalone maintenance solution:

- Automation: When a machine event such as an alarm, downtime, or condition threshold is met, an automated workflow can instantly create a work request or work order in the CMMS. [Video from here]

- Notifications and Alerts: Whether you use a CMMS or not, machine data can be used to automatically alert the right person when a given condition occurs, such as a machine downtime. For example, an email or text could be sent to a maintenance manager.

- APIs and Integrations: MachineMetrics has native integrations with several CMMS, such as MaintainX, FiiX, and Upkeep, and with non-maintenance systems such as ERP and MES systems.

- Real-Time Machine Data: MachineMetrics captures comprehensive, real-time machine data - such as alarms, conditions, and cycle counts - that indicates when a machine soon requires maintenance. When a failure is imminent, the right person can be immediately notified.

Explore All The MachineMetrics Integrations

Reporting and Analysis

CMMS systems do have reporting functionality, allowing managers to drill down and better understand plant, equipment, and staff performance. This can allow for deep analysis, such as how long it takes the team to resolve a failure, and what work orders are outstanding.

But as customized and sophisticated as these tools may seem, they are unlikely to provide highly accurate data, which can lead to flawed assumptions and poor decision-making.

With the core of maintenance being “keeping machines running,” it is essential for CMMS systems to have a robust dataset provided by the equipment itself. Only data straight from the equipment can tell the full story on machine utilization, downtime, MTBF, OEE, etc. This will help maintenance teams establish benchmarks and prioritize the biggest opportunities.

Use MachineMetrics to collect and analyze real-time machine conditions and automatically create work orders in your CMMS to automate maintenance activities.

Use MachineMetrics to collect and analyze real-time machine conditions and automatically create work orders in your CMMS to automate maintenance activities.

Steps in Data-Driven Maintenance

In the industrial internet and IoT age, maintenance strategies are maturing quickly. They’re delivering a higher value, offering an additional path to process optimization, and providing greater efficiency. Here are a few steps to achieving a data-driven maintenance program.

1. Data Collection

Data collection is the driver for IoT-enabled industrial maintenance solutions. Many fragmented solutions require a patchwork of devices, software, and connectivity hardware. MachineMetrics is the only solution that works across harsh industrial environments and with any OEM and generation of equipment. With MachineMetrics devices, installation of data capture devices is quick and intuitive - it works out of the box. Further, it is extensible, enabling the data to be used by other systems, such as CMMS, via native integrations and APIs.

2. Detection

Detecting machine performance and health are critical to success. MachineMetrics allows the connection of both digital and analog sensors. It can capture PLC data and standardize it to include sensor measurements, alarms, speed, load, feed rate, and more. And because MachineMetrics devices process data at the edge via EtherNet, Wi-Fi, or even cellular, detection is extremely reliable. The real-time data returned from the analytics platform provides users with the capability for quick action when machine conditions warrant.

3. Predictions

Every manufacturing company’s needs are different. While condition monitoring and predictive maintenance use predictions based on AI-powered advanced analytics and machine learning, the holy grail of data-driven maintenance programs is prescriptive maintenance. The value of scenarios based on historical machine data, real-time conditions monitoring, and deep analysis of variables such as oil life, vibration, and high-frequency data cannot be overstated. These highly accurate, relevant, and actionable predictions set the MachineMetrics platform apart from the rest.

4. Health Administration

Data-driven maintenance isn't about just getting on top of mechanical issues. It’s about maintaining the health of the entire factory or shop floor. The same advanced analytics that drives the predictions and manages the detection offers deep visualization of machine health by shift, hour, and product type. This empowers maintenance staff and managers alike to hone their maintenance strategy further and maintain health before problems and failure occur.

Less is More When it Comes to Data-Driven Maintenance

Companies have traditionally spent countless dollars on maintenance strategies over the years. Before the power of big data made another path possible, these dollars came in high parts costs, unnecessary downtime, and other variables.

Data unlocks a simpler, more adaptable approach to maintenance. With data-driven maintenance, maintenance managers have real-time data and insights in their hands. They can do what’s required confidently without extra or shortage. The lower holding cost for parts, longer tool life, and more accurate replacement at an optimum time mean higher productivity, lower cost, and higher efficiency.

The result is maintenance driven by megabytes and not billions of dollars. It means a staff trained to use data to understand a factory's machines in a way not possible before. And it means using data to run manufacturing maintenance instead of using maintenance to generate data.

Improving Performance with Data-Driven Maintenance

Companies using a machine data platform like MachineMetrics can improve efficiency, lower costs, and unlock hidden capacity. They can even use the same system to improve their overall machine health and build a data-driven maintenance program.

MachineMetrics can help you leverage accurate data to add significant value to a CMMS, or simply manage maintenance more effectively. By leveraging real-time data and actionable insights on machine conditions, companies can take their maintenance performance to a level it’s never attained.

Take Maintenance to the Next Level

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments