As Industry 4.0 continues to mature across manufacturing enterprises globally, many assume that new technologies will replace old methodologies to spur continued improvements in efficiency and production. And while that may be the case for some applications, it’s also true that these new technologies can complement existing practices.

One such methodology that aligns exceptionally well with the value offerings of Industrial IoT applications is that of Total Productive Maintenance (TPM). Built on the 5S foundation popularized by lean methodology, Total Productive Maintenance is a maintenance model that helps alleviate downtime and improve production. In this model, downtime for maintenance is included in manufacturing as part of manufacturing scheduling. Operators and technicians, those most familiar with the equipment, are given responsibility for certain aspects of regular and preventive maintenance as part of their responsibilities.

Eight Pillars of TPM

Total Productive Maintenance aims to improve productivity, efficiency, and safety while building a culture that includes basic maintenance into standard operating procedures for line staff. This consists of eight pillars of activity:

- Autonomous Maintenance – Operators monitor the condition of their workstations.

- Process and Machine Improvement – Leads and operators collect information and prioritize maintenance tasks.

- Preventive Maintenance – Operators perform basic preventative maintenance tasks.

- Early Equipment Management – Leads and operators proactively assess new components and report on maintenance records using early equipment management.

- Process Quality Management - Quality improvement ideas emanate from shared operation and maintenance responsibilities.

- Administrative Work – Outcomes based on data are shared with leads and operators.

- Education and Training - Continuous improvement leads to continuous education of operators and leads.

- Safety – The improved equipment performance provides a safer operating environment.

Aligning TPM with Industrial IoT

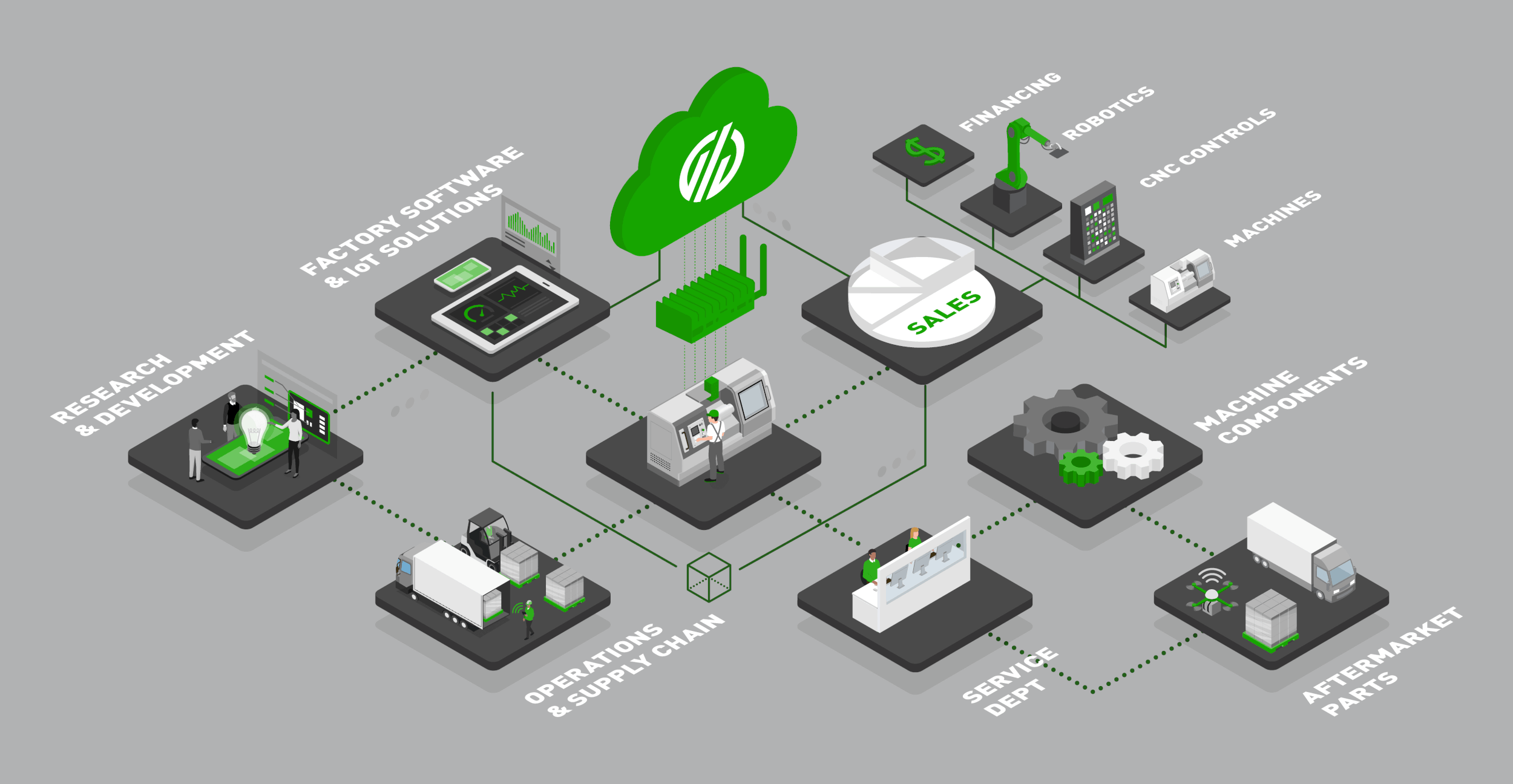

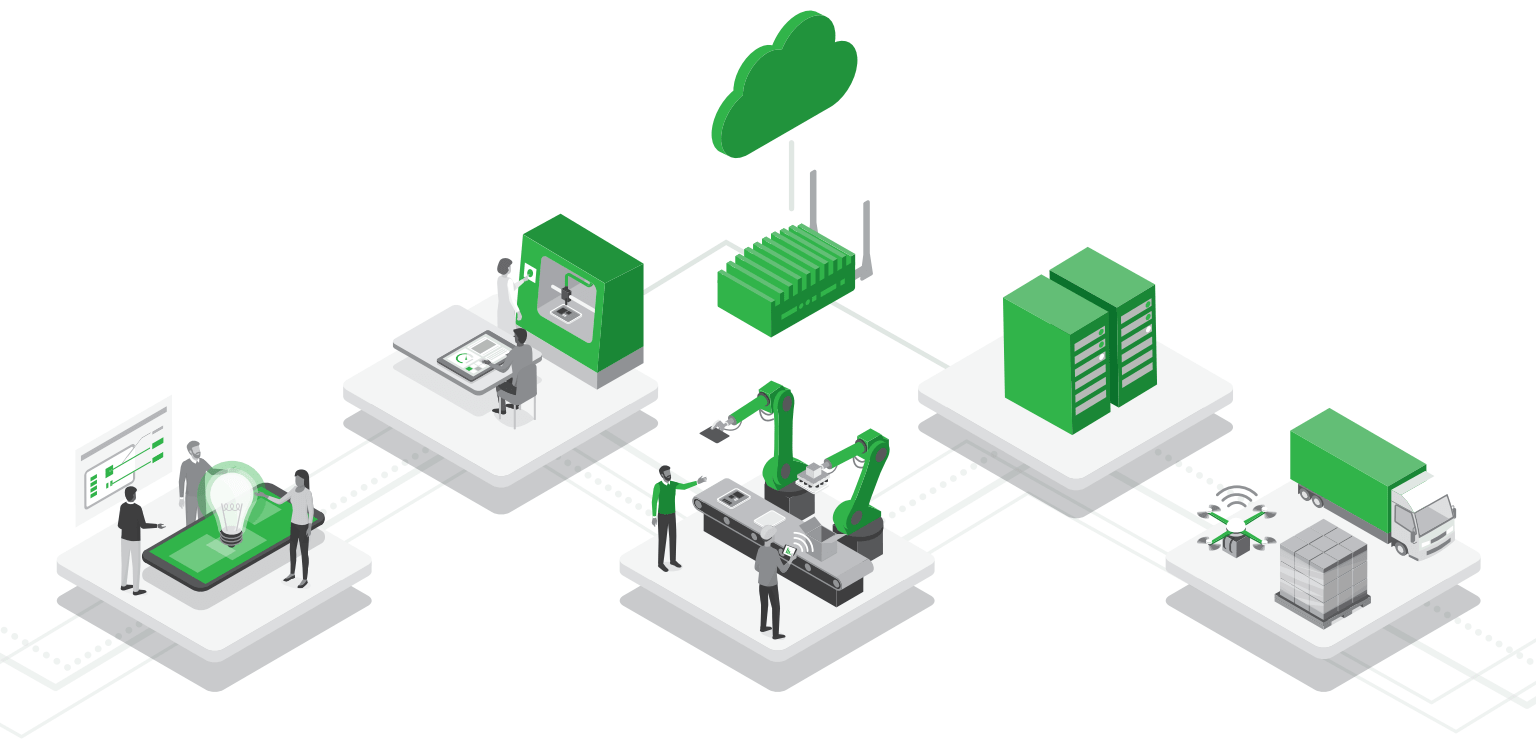

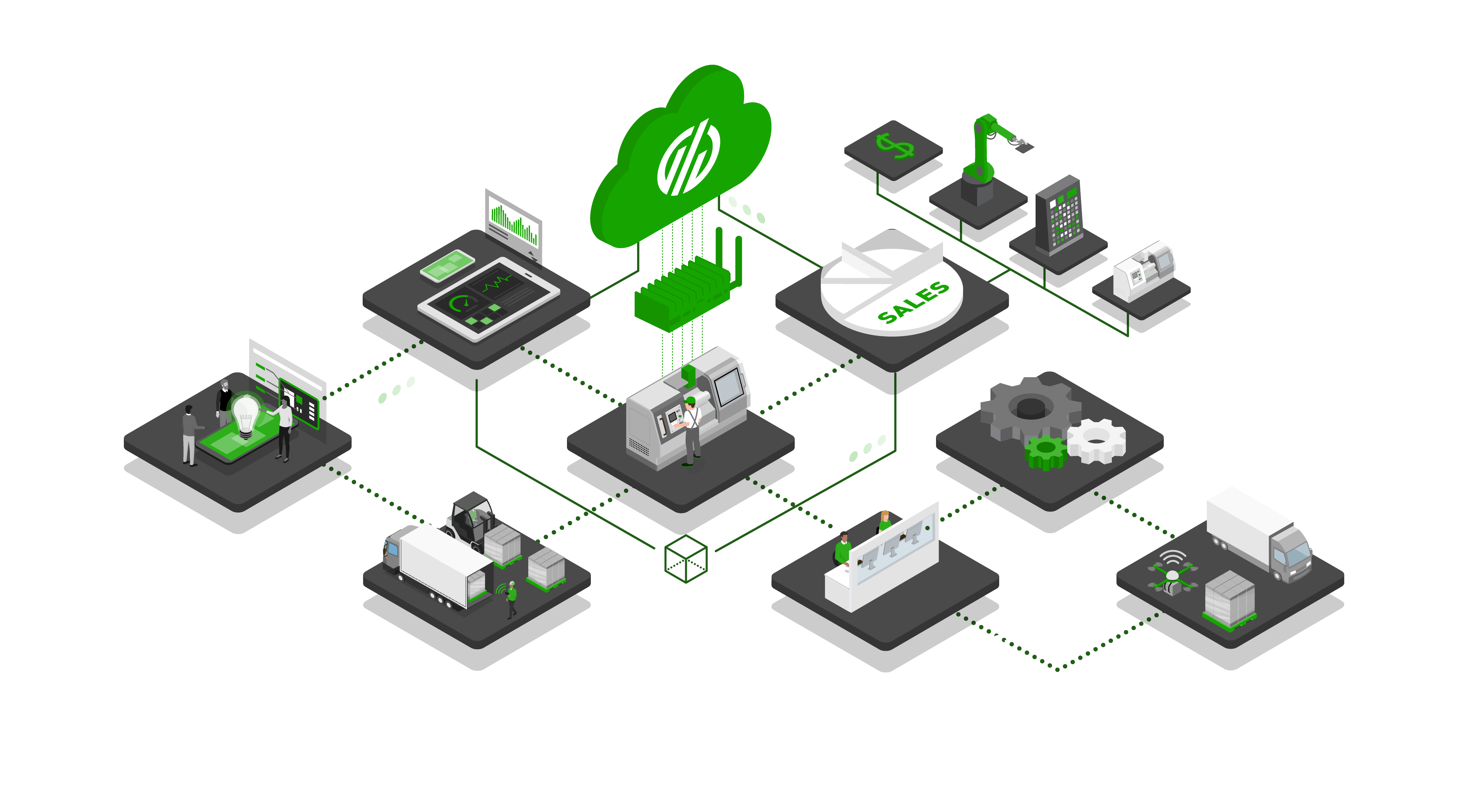

So how does Total Productive Maintenance align with the value offerings of the Industrial IoT? Rather than being a methodology at odds with new technology, it’s easy to see that programs such as Total Productive Maintenance are almost tailor-made for IIoT. A strong and comprehensive Industrial IoT platform will offer several things:

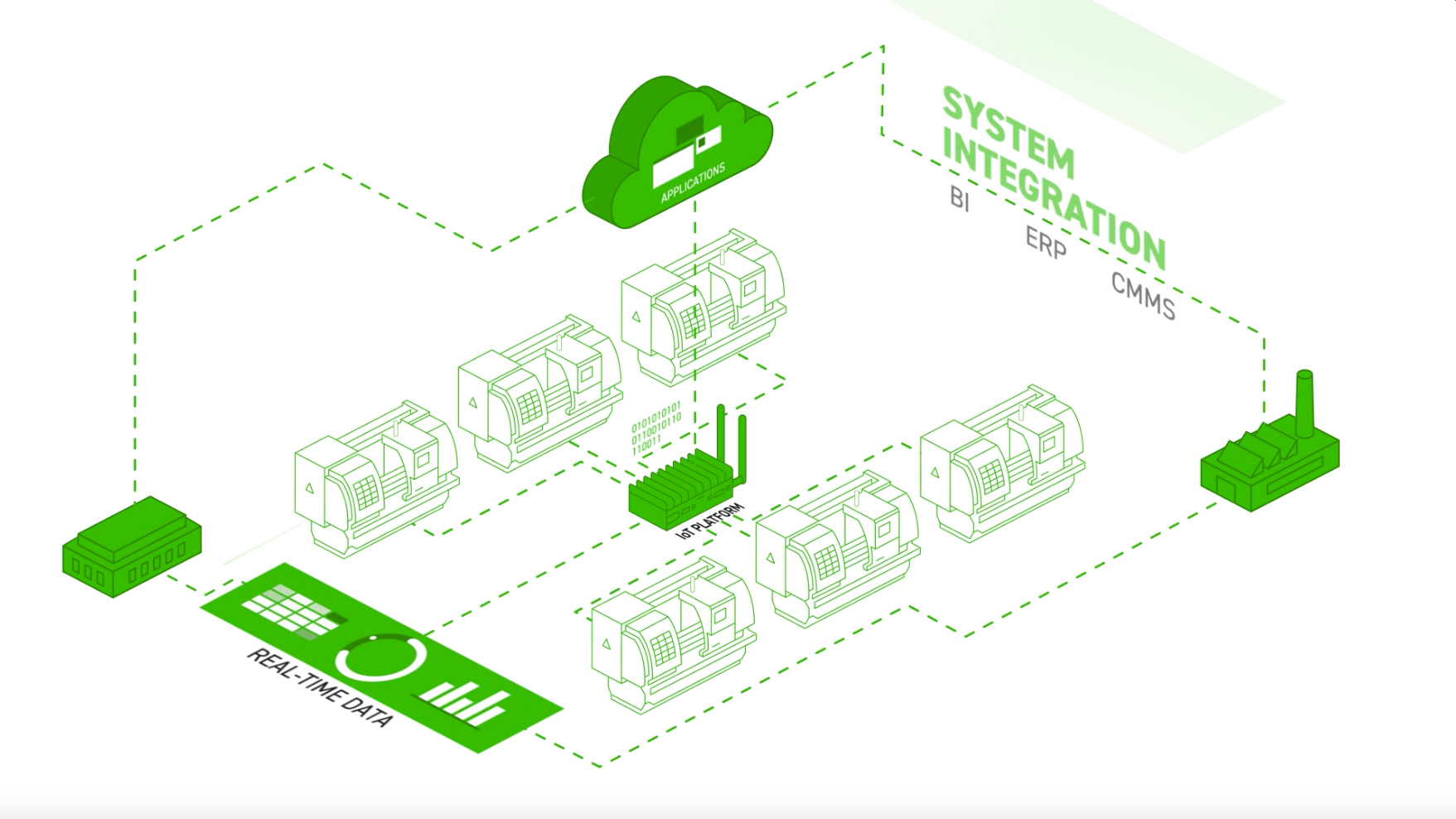

- First, it’ll offer devices in the form of sensors, temperature sensors, wear sensors, and other equipment that can be fitted to any machine regardless of age. This brings all the equipment within a factory into the ecosystem of full data collection. This ecosystem includes state-of-the-art edge devices to simplify IoT connectivity across ethernet, Wi-Fi, and cellular technologies. Connecting directly to equipment PLCs allows even older, legacy equipment to be brought in line for data capture.

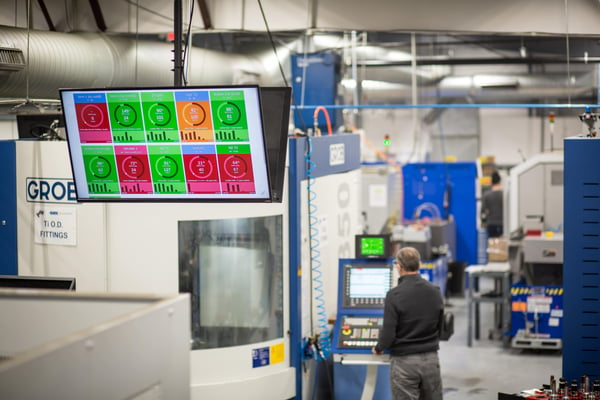

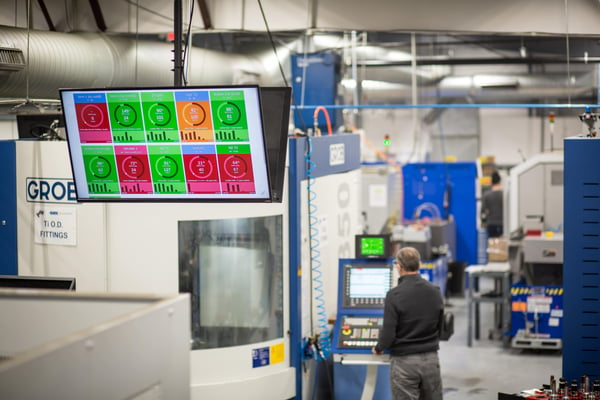

- Second, an IIoT platform will offer full visualization of the factory. Many have heard of the "Hidden Factory," where efficiency and higher productivity are waiting to be unlocked. This efficiency is realized through data visualization in real-time and at the fingertips of the operators, technicians, leads, and managers who need it. It’s estimated that visualization alone can increase efficiency by as much as 20%. This visualization is captured by intuitive, dynamic, and customizable dashboards that display production data and equipment conditions. These same dashboard views are available through tablets, phones, and other portable devices, allowing for decision-making at the point of need.

Shop floor visualization is important at multiple levels of the organization, from technicians to plant managers.

Shop floor visualization is important at multiple levels of the organization, from technicians to plant managers.

- Third, an IIoT platform should allow full monitoring of machine conditions and advise an action to be taken. This monitoring is done through data analytics collection. As machine performance data is collected, it can be used to analyze historical trends, understand real-time performance, and send notifications for action to be taken.

At MachineMetrics, the goal of the data is to provide you with real-time visualization and analysis that fully aligns with all three. And data is what makes MachineMetrics so good at what we do. MachineMetrics helps customers improve their Overall Equipment Effectiveness and manufacturing efficiency and identify bottlenecks in production by driving value through analytics. This improvement drives value through the use of analytics throughout the operation.

Benefits of TPM

One key driver of Total Productive Maintenance is that it uses the Lean methodology tool of 5S. By creating an environment where the workplace is highly organized and standardized procedures, safety, quality, morale, maintenance, and other key performance factors are impacted.

- Fewer breakdowns – Not only are operators responsible for monitoring the condition of their equipment, but they’re also empowered to perform autonomous maintenance repairs that were traditionally reserved for maintenance technicians. Drawing on another pillar of Total Productive Maintenance, because the equipment is proactively assessed by maintenance staff and operators, there is more a spirit of collaboration and a deeper understanding of the day-to-day functions and potential issues the equipment will encounter. These combined efforts result in the ability to develop predictive maintenance that results in fewer breakdowns.

- A safer workplace – Other pillars of Total Productive Maintenance work together to create a safer workplace. Because safety is made a priority facility-wide, awareness of potential safety hazards is heightened. This awareness continues into the education and training, where they can be folded into any continuous improvement efforts organically, thus becoming part of the culture.

- Better overall performance – As Total Productive Maintenance begins to impact maintenance efforts and reduce breakdowns, morale increases positively, and collaboration creates a team environment. Education and training and a focus on quality maintenance contribute to this. The overall efficiency of the operation is significantly improved. Total Productive Maintenance can be measured using Overall Equipment Effectiveness (OEE) calculations to establish metrics that show the success and improvement of the efforts. Underperforming equipment and processes are quickly identified and pushed to the team for consideration using TPM principles.

How to Implement Total Productive Maintenance (TPM)

TPM uses the Lean methodology tools of 5S and may often be a part of a Lean implementation. It may also be used for the deployment of IIoT and factory monitoring. Both require a commitment to undertake Total Productive Maintenance as an improvement process whose goal is to be incorporated into the company culture. There are five basic steps for TPM implementation.

Step 1: Identify a Pilot Area

A pilot area gives the TPM team something to use as a proving ground. It builds buy-in from employees and allows them to see the benefits at work. Buy-in is reached easier if the implementation team includes staff members from many different roles and hierarchical levels.

The choice of a pilot area will, of course, include specific equipment. One successful trick is to find an obvious, immediate improvement to get a "team win." This win doesn’t fully vet the process but instead builds confidence upon success. It also makes it easier for employees to see the path for more challenging areas of improvement.

Another way to choose the equipment for improvement is to pick a bottleneck. This bottleneck may involve several pieces of equipment and may result in some up-front downtime. But by focusing on an area where production "always" jams, the benefits could be higher.

The final way to select a pilot machine is to focus on the equipment that always seems to have the greatest maintenance downtime. It may be a legacy machine or one with fewer run hours and training. But it’s the headache everyone will enjoy resolving.

Step 2: Restore Equipment to Prime Operating Condition

Highly anchored in 5S is the restoration of equipment effectiveness to its prime operating condition. Before a TPM program, operators, technicians, and maintenance staff may have created years of "workarounds" to address real and perceived problems. By deploying the 5S tool to the equipment itself, it’s returned to peak condition.

Steps to facilitate this process include before and after pictures. It also requires removing excess tools, equipment, and supplies not required for daily operation.

Organizing tools in shadow boxes or drop-down harnesses and cleaning the area around the machine are also important. And from this, formal 5S logs should be added with an audit step added to the production SOPs to ensure the effort remains in force over time.

Step 3: Measure OEE

Overall Equipment Effectiveness (OEE) is a great tool to establish a performance metric and set targets for improvements. OEE is not one metric. It can be calculated with formulas to measure quality, performance, or availability.

The established goals of the TPM team will determine which one, or which combination, of metrics to use.

OEE tracking is a great way to establish data-driven insights that can help inform managers and decision-makers of future goals for factory automation projects and IIoT deployments. It allows companies to benchmark and see the progress of TPM as the metrics play out over time. And it helps the team see what to work on next for further improvement.

Because unplanned downtime is the largest factor in low efficiency, an interval of two to four weeks is recommended to get a clear picture of the team's conditions and issues. It also helps build consensus for categories of downtime to be used in future automation in production monitoring.

Step 4: Address/Reduce Major Losses

With a reliable amount of data points over time for unplanned stops, the team can begin to work on improvements. The most obvious area to address is the largest source of unplanned downtime on the category list.

Here, other Lean and Six Sigma tools can be used, such as fishbone diagrams, Pareto charts, etc.

Root cause analysis should be a vital component of the considerations. By analyzing through observation, physical and photographic evidence, and production history and comparing those findings to possible causes, the root cause of the problem can be determined.

After changes are made, monitor and record the results. It may be required to run through the process again if the results don't work.

However, it’s also acceptable to run through the process again to try and reach higher improvement levels for changes that did work.

Step 5: Implement Planned Maintenance

Once the change has been validated as effective, it can be rolled into the proactive maintenance plan.

This maintenance may include heat and temperature monitoring for equipment where the root cause identified heat failure. Or it could involve vibrational analysis for machines that were the subject of high stress or sheering forces.

It’s also at this stage that the maintenance interval should be established. This interval should be based on run time rather than calendar dates.

And records and charts should be kept to identify realistic intervals for proactively replacing wear parts or establishing predicted failure rates. These procedures, once mature, can also be added to a production monitoring IIoT software program later to optimize the system further.

Forging Ahead

TPM is different from traditional preventive maintenance. In traditional maintenance programs, a time-oriented list is utilized based on OEM recommendations. This maintenance method doesn’t factor in production materials that put an aggressive or mild strain on equipment reliability or condition, meaning that equipment malfunctions sooner than expected or much longer than expected. One adds cost in the form of breakdowns, and the other adds cost in replacing parts that are still in optimal working order. MachineMetrics helps customers with advanced machine learning, deep analytics, and intuitive and customized dashboards that allow operators, technicians, and managers to act in real-time at a level previously impossible.

Traditional maintenance isn’t predictive. It doesn’t have the ability afforded IIoT technology to schedule the maintenance in conjunction with changeovers or other scheduled downtime to reduce overall downtime. And being matrix-based rather than analytics-based, traditional maintenance relies on pre-set time to perform maintenance. We've seen this time and time again at MachineMetrics. Our software brings the benefits of Industrial IoT to the production floor, allowing customers to develop dynamic, data-driven maintenance programs that save time and money.

Intuitively, the effectiveness of TPM is made possible by the value offerings of the Industrial IoT. By providing machine performance and health data, the IIoT allows for accurate and actionable capture of information that makes the full realization of TPM possible. In doing so, the potential of the "Hidden Factory" is unlocked, and digital lean can be realized through the use of IIoT technology by building on lean principles.

Header image source: Unsplash

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Shop floor visualization is important at multiple levels of the organization, from technicians to plant managers.

Shop floor visualization is important at multiple levels of the organization, from technicians to plant managers.

Comments