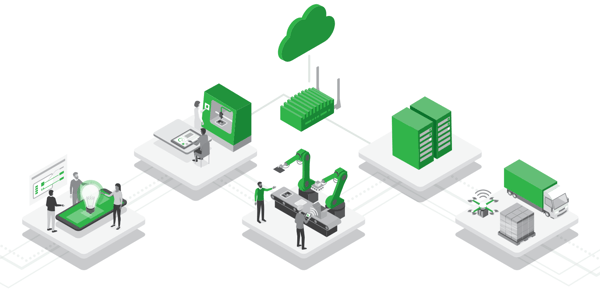

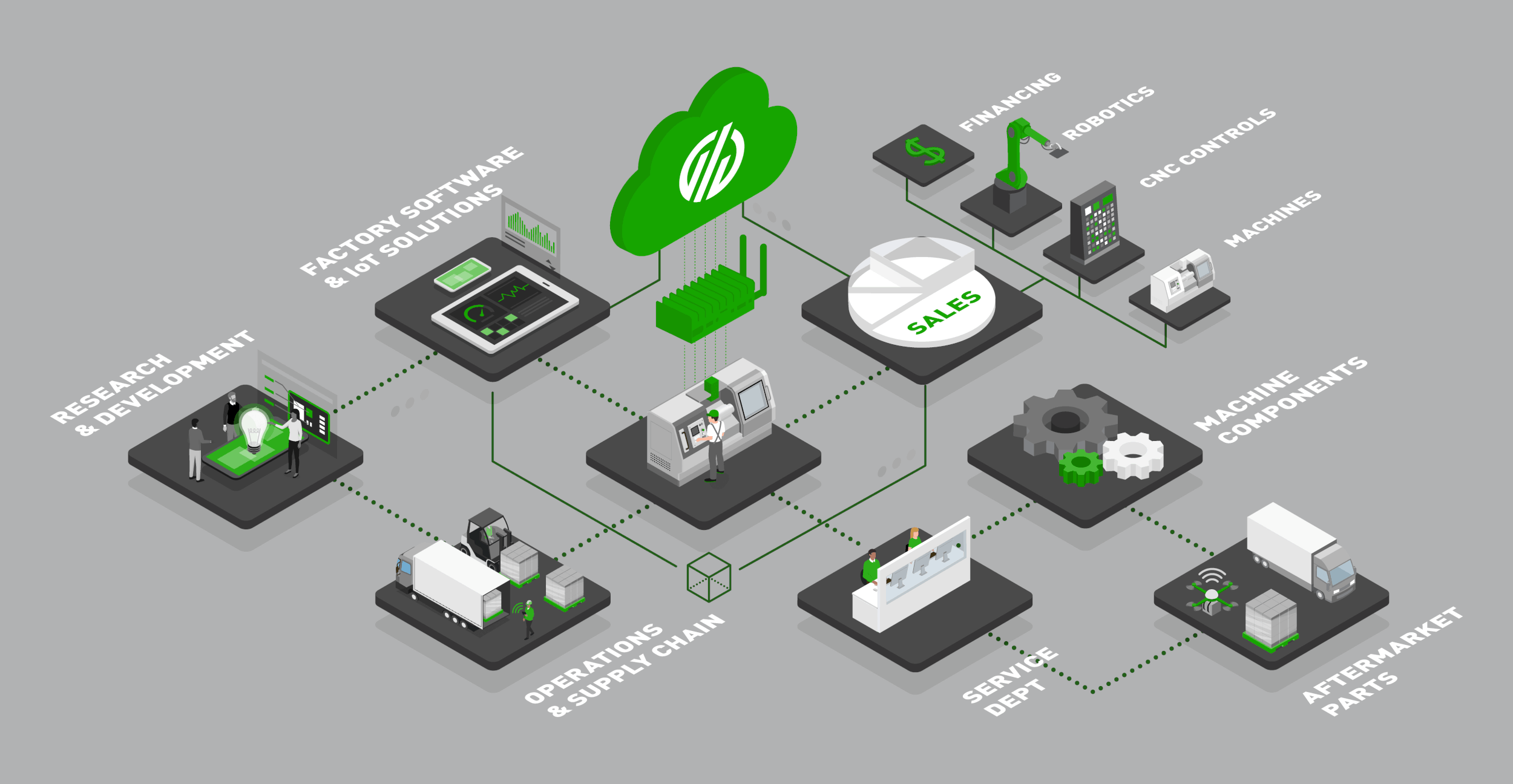

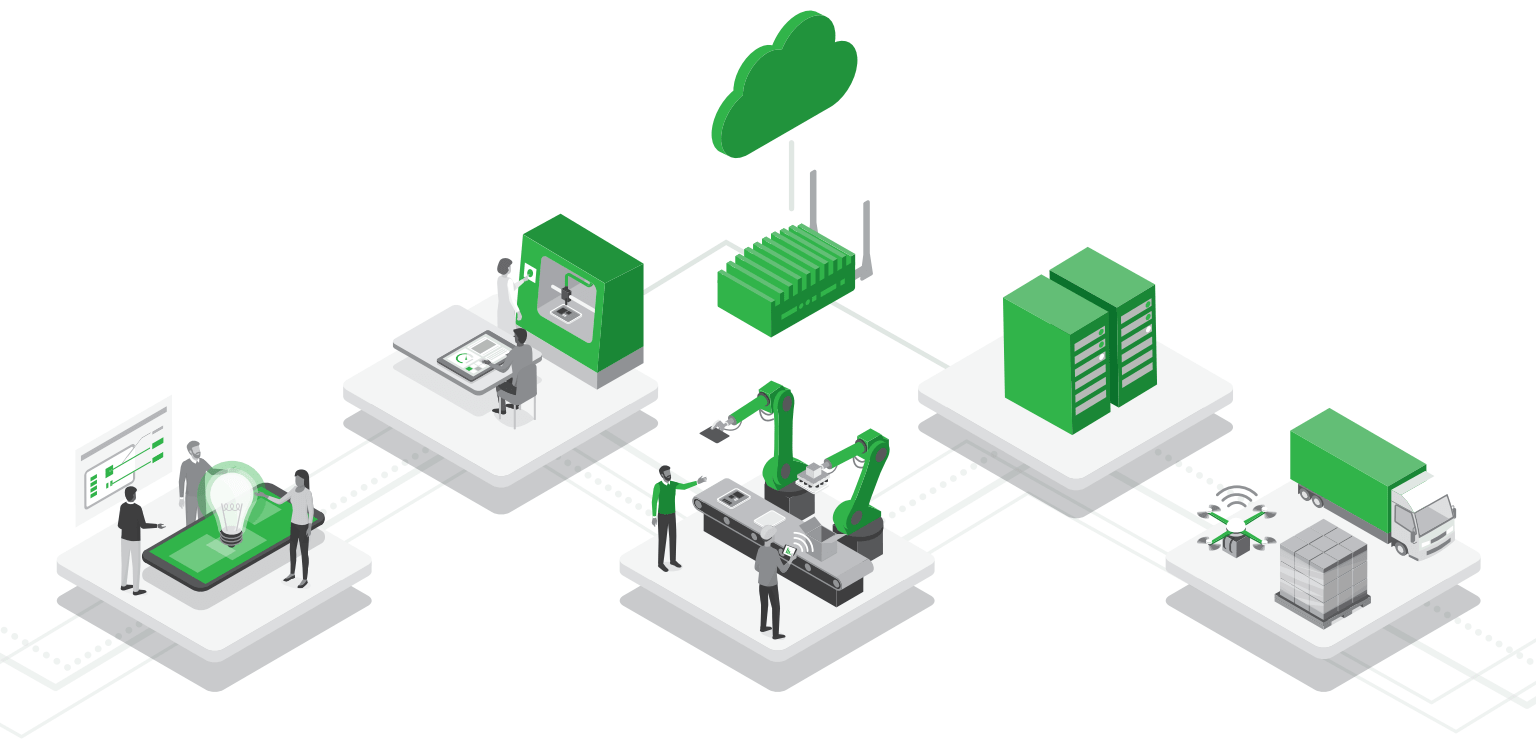

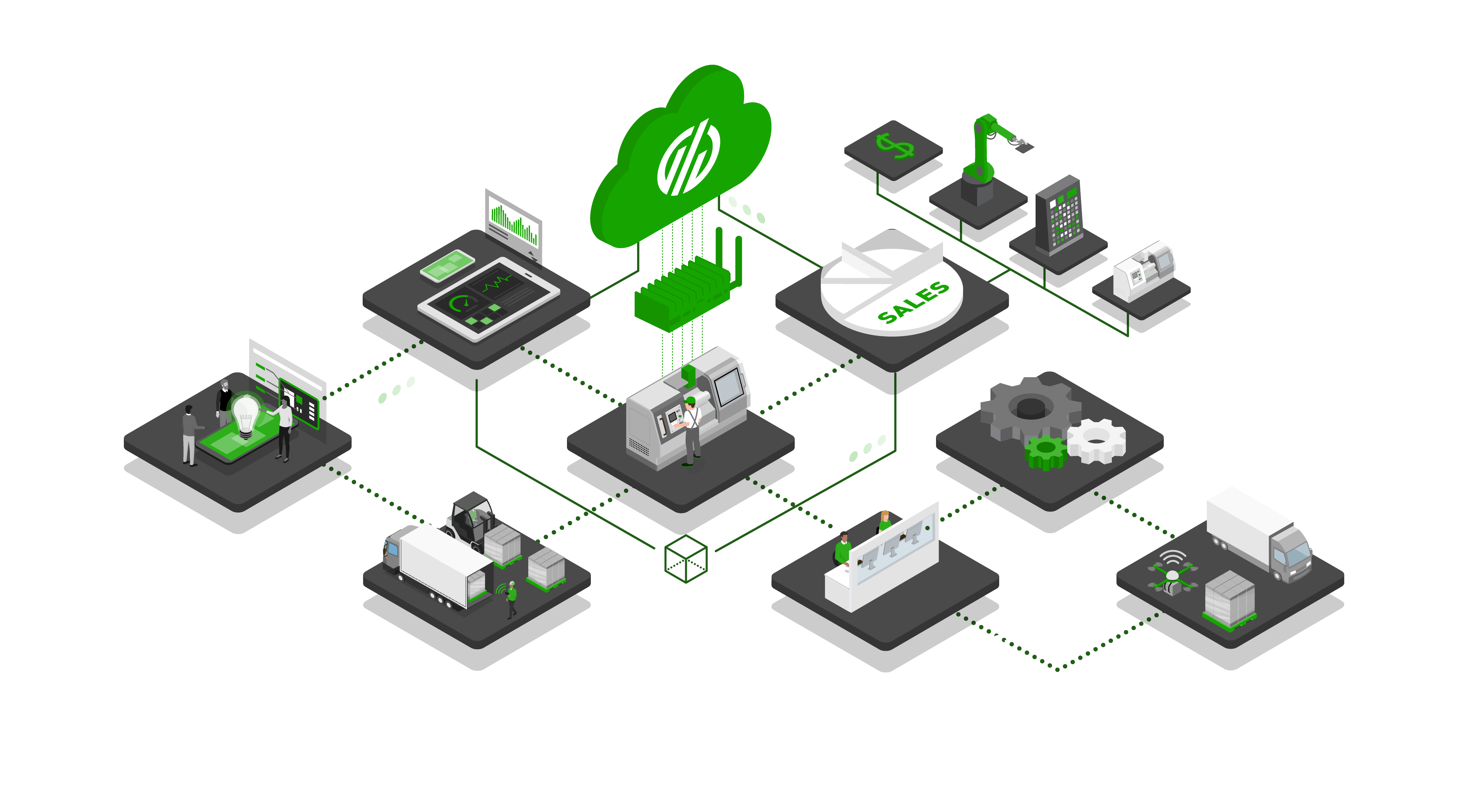

Summary: IoT benefits companies in the manufacturing vertical by reducing costs associated with unexpected downtime, creating a digital twin that can be used to track assets and perform complex simulations, improve worker safety and satisfaction while offering deep, actionable insights into process and equipment improvements. IoT can also empower manufacturing companies with agility and resilience so they can keep thriving, no matter what.

Saving Money and Making Money With IIoT

Businesses in every sector are deriving massive value from IoT technology and the growth of the industry is a reflection of this pattern. McKinsey & Co predict that IoT could reach $11.1 trillion in economic impact by 2025. Data collected from IoT devices is growing at a staggering rate as well - Cisco predicts data from IoT devices could pass 800 zettabytes by the end of 2021.

But why is this happening and what are IoT devices doing for businesses that has resulted in such explosive growth? It can be simplified into two overarching categories: saving money and making money. One example of IoT generating revenue is when it enables a business to add a subscription model to their offerings, creating repetitive revenue.

The ways in which the Industrial Internet of Things reduces costs varies by industry. In the manufacturing industry, IoT saves money by: lowering overall maintenance costs using predictive maintenance principles; increasing worker safety during training and repairs; bridging the gap between floor workers and executives; identifying and resolving bottlenecks in production, as well as offering insight into future changes and opportunities before money is spent toward action. We now drill down further into examples of specific cost-saving use cases of IoT in manufacturing.

1. No More Surprise Downtime With Predictive Maintenance, Not Scheduled Maintenance

Do you know how much unplanned downtime is costing you? If you are representative of 80% of companies, the answer is likely, “No, not really. Not exactly.” When machinery fails, entire production lines can come to a halt. In a research study from ServiceMax called “After The Fall: Cost, Causes and Consequences of Unplanned Downtime,” they found that 70% of companies aren’t sure when their production machines require maintenance or upgrades. This led to 82% of companies in the study experiencing unplanned downtime within the past 3 years, with an average outage duration of four hours and a median cost of $2 million.

Old-school maintenance usually presents in one of 2 ways:

- Equipment breaks > production halts > you wait for the maintenance person to come fix it, which sometimes requires ordering parts that aren’t on hand. You pay workers to twiddle their thumbs while the corporate bank account starts to resemble a bucket with a hole in the bottom. Alternatively, you risk increased churn as employees who expected paid hours that week in order to feed their families, begin losing faith and trust in your company. This can then generate an air of negativity and dissent causing them to seek more stable employment.

- You schedule downtime at a somewhat arbitrary interval > you wait for the maintenance person to remove what may be perfectly good parts and replace them with new ones, sacrificing money and production time along the way. Neither solution is efficient, as they both ultimately waste resources.

Here’s what modern maintenance looks like:

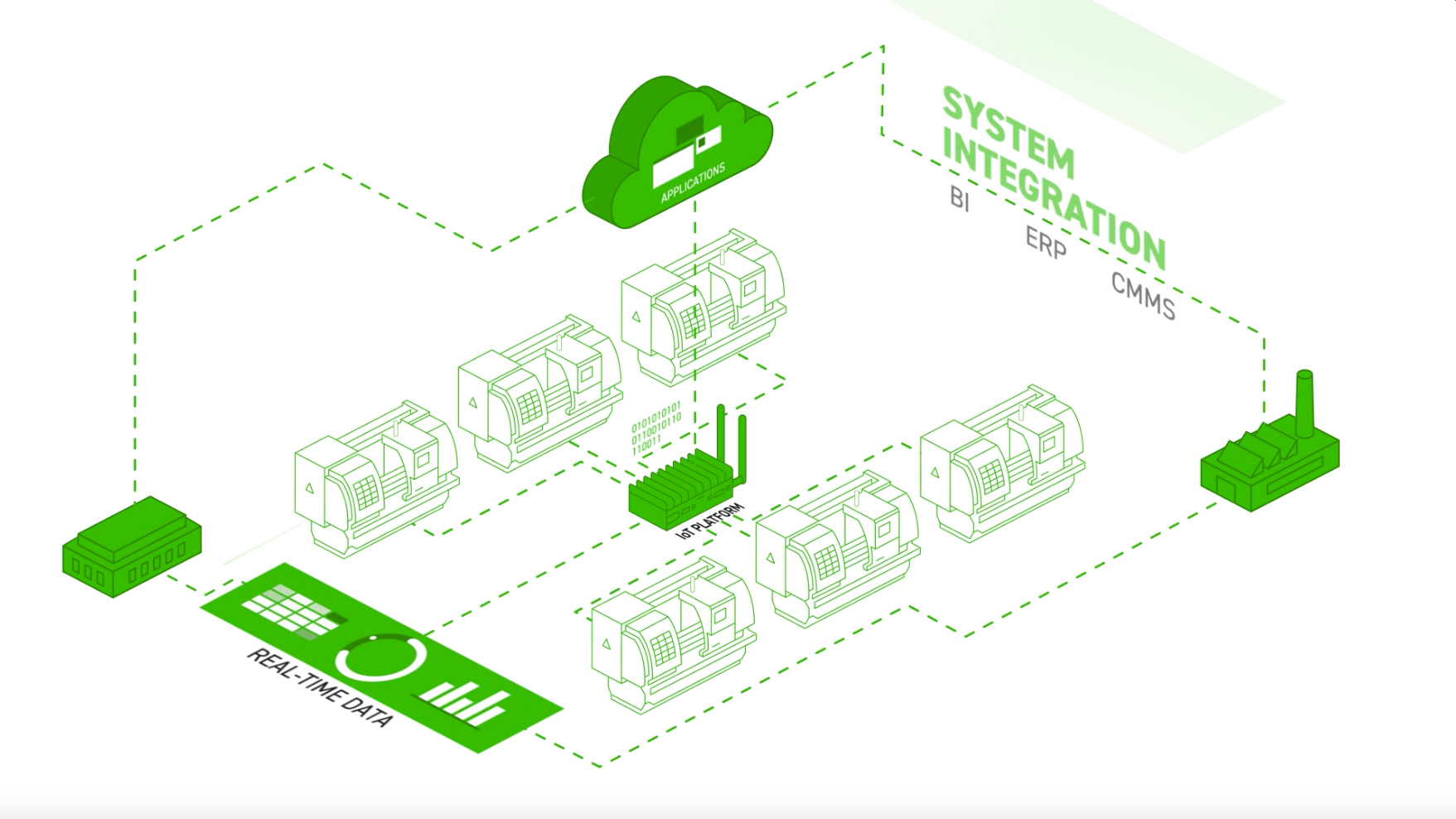

The machines on your production floor are all equipped with small Internet of Things (IoT) devices that monitor a variety of data including usage, uptime, quality, energy consumption, inventories of parts, and a log of system disruptions. If anything goes wrong—or starts to go wrong—the right people are instantly alerted with a notification. Using historical data, the IoT-enabled predictive maintenance system will also notify you when a part is nearing its end-of-life and should be replaced. It can also let you know when, if, and how the quality of output is slipping or when a machine is consuming more resources, such as power and water, than expected.

Connected equipment gives manufacturers access to valuable data, which can tell them a story about the historical performance of the equipment, as well as alert them of upcoming failures.

Because all of your machines are equipped with this same technology, your parts inventory is just like the Goldilocks’ fairytale outcome—it’s just right. You have the parts you need when you need them, but you’re not wasting precious space storing items you don’t and won’t need in the near-term future.

Predictive maintenance saves you money by:

- Reducing costly unplanned downtime

- Replacing parts only when they need to be replaced based on historical data or when they show signs of malfunction before they hit critical failure. Problem diagnosis becomes faster and more accurate than ever

- Carrying only the parts you need

- Remote monitoring with real-time alerts expedites response times

- Minimizing employee churn and customer dissatisfaction due to quality issues.

2. Eyes Where You Never Knew You Needed Them

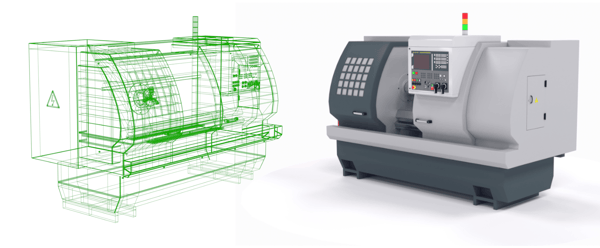

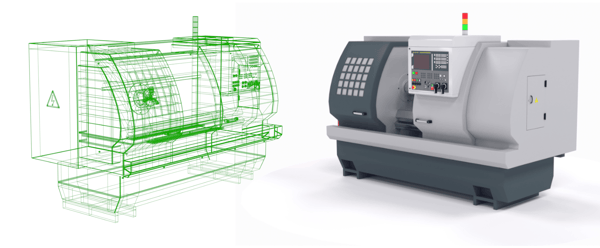

Machine learning—a subset of artificial intelligence (AI)—is the technology that underpins maintenance predictions. One way to get the most out of IoT and machine learning in manufacturing is to combine them into a “digital twin.” A digital twin is used for complex, intelligent simulations that take into account the past behavior of your machines and their current condition in order to predict their future behavior.

Predicting future behavior via this channel leads to reduced catastrophic disruption and overall maintenance costs as well as increased production efficiency. Digital twins can also assist with design, employee training, and worker safety—especially when combined with other technologies such as virtual and augmented reality. Imagine a worker who is able to visualize the broken inner workings of a machine without needing to remove any protective shielding. It’s like having eyes inside your machines, all the time.

A digital twin is a virtual representation of a physical asset, in this case a CNC machine.

How a digital twin based on IoT benefits your company’s bottom line:

- Advanced predictive capabilities through complex simulations that can involve one piece of machinery or the entire production floor. Be prepared for anything.

- Fewer disruptions caused by costly and time-consuming failures

- Reduced overall maintenance costs

- Increased uptime

- Improved worker satisfaction and safety, reducing churn rates and training costs.

3. Empower, Involve, and Protect Your Shop Floor Workers

In the manufacturing vertical, it isn’t uncommon for there to be a disconnect between workers on the production floor and executives and analysts who are assumed to operate separately in their ‘ivory towers’. This may mean your business could be missing out on valuable information as well as reducing your employees’ investment in its success.

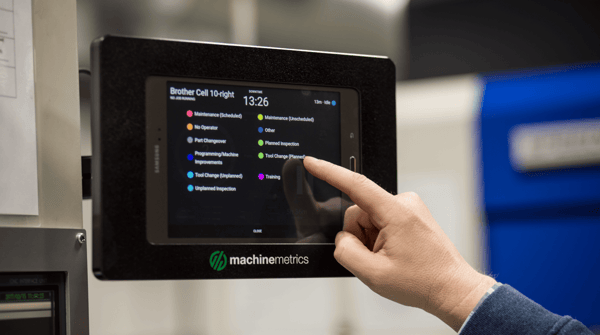

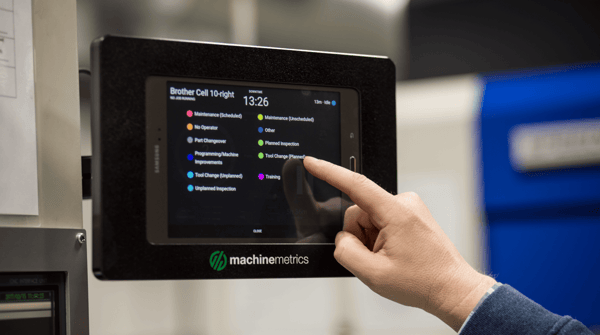

With MachineMetrics IoT solutions, workers on the floor can provide human input to be considered with the rest of the data. With touchscreens on factory-floor machinery, operators can add human context to machine data which helps to bridge the gap between job roles, offering deeper understanding to a host of previously undetected issues.

By providing an interface for operators to interact, MachineMetrics is able to use both human and machine data to understand performance.

By giving production workers a voice the business can move toward progress as a unit, with investment at all levels. In the same vein, well-maintained equipment means employees are safer at work and have fewer unexpected off days. Factors such as these can offer a boost toward positive company culture which can reduce sick days, up productivity on the clock, and reduce churn and training costs—a major concern for many manufacturing companies.

IoT benefits your employees and shop floor workers in ways which reduce costs by:

- Finding unseen problems by bridging the gap between job roles

- Increasing worker safety so fewer costly accidents

- Improving worker satisfaction by offering ways for them to provide input and become invested in the company

- Boosting positive company culture so that employees are invested in success, more productive and efficient and possibly taking fewer sick days

- Reducing churn and costs for acquisition and training.

4. Break Your Bottlenecks

Bottlenecks limit the overall production capacity of your company. However, it’s not always apparent where these obstructions sit or the degree to which they impact productivity on the shop floor. IoT can pinpoint which areas are slowing you down the most.

Is there one machine that breaks more than the rest, or that needs an upgrade because its production speed is slowing down overall output?

Are there time periods during which some machines are under-utilized? Are your processes holding you back—and if they are, do you have actionable solutions to fix them?

The benefits of IoT reign supreme when it comes to breaking your company’s bottlenecks. When combined with machine learning on an intelligent platform, you’ll soon discover how accurate, historical data from industrial IoT sensors can provide actionable insight into where improvements can be made. It can show you which steps to take now for the highest payoff as well as continuing to offer optimization insights based on real-time data.

IoT reduces costs by prioritizing and reducing the impact of productivity congestion by offering process optimization and analysis as well as conditional analysis to make sure human and machine work in perfect harmony.

5. The Power to Ask, “What If?”

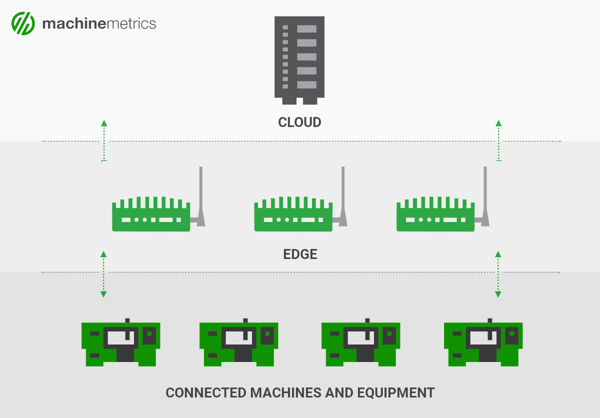

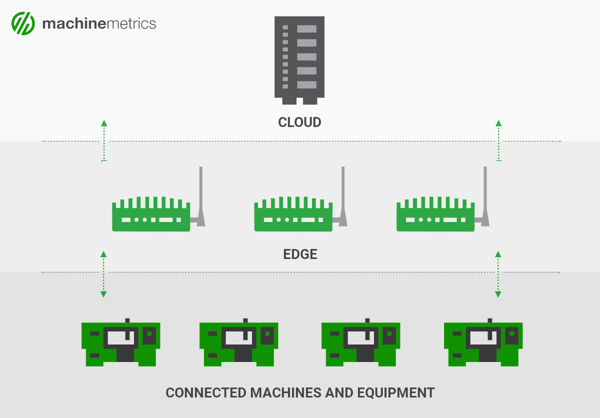

When you have sensor data that is continuously aggregated and analyzed via both the Edge computing (or computing at the sensor itself) and via the Cloud (online with vast data storage and extreme speed boosts), you gain the ability to predict the future.

Both the Cloud and Edge play important roles in the collection and processing of data. What's the difference between Edge and Cloud?

Let’s qualify that with a “Not perfectly”. No system ever is perfect. But the more accurate your data and the longer history of data you have, the more likely it is that your predictions will prove to be correct.

What does this mean for your company? IoT saves money by reducing risks to worker safety as well as machine malfunction risks such as catastrophic failure and unexpected downtime. When you know ahead of time what is dangerous or what could break, you have the capacity to fix the problem before it impacts you.

When using a digital twin, IoT also lets you look at your factory floor and the processes you use to run it and say, “Well, what if we changed this? What if we got another one of these machines or changed the production schedule or utilized this machine more frequently?” It can help you predict how your changes will impact your business efficacy before you implement them, saving you time and money. It can even tell you which things will be most effective at saving money (or increasing revenue, or reducing energy consumption, or whichever other factors you are most interested in).

Industrial IoT platforms like MachineMetrics give you the chance to look at your data in an easy-to-comprehend, human, actionable way. The insights we provide are deep but well-organized. Easy reporting and a color-coded dashboard let you see at a glance where you stand and where improvements can be made.

More than the day-to-day what-ifs, IoT can help you answer the big questions too. What if we need to pivot in a short period, how could our machinery handle that? If we were approached tomorrow with a massive order, what level of output can we reasonably sustain and over what time period?

Opportunity comes to those whose eyes are open to the information at their disposal.

IoT offers your company agility in the face of adversity. It provides you with stability in times of calm. It gives you the information you need to chart your next step regardless. Flexibility and resilience come from knowing where you’re at and where you’ve come from, because, with that, you know where the future of your business can lead you.

MachineMetrics is accelerating industrial digital transformation by providing an intuitive and flexible platform to easily collect and transform data from any piece of manufacturing equipment into powerful, actionable applications that reduce machine downtime, optimize capacity, and drive increased throughput and profitability for factories. Right now, hundreds of manufacturers have connected thousands of machines to MachineMetrics across global factories. Get a demo.

Ready to connect your shop floor?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments