This article is part of a series addressing the most pressing concerns manufacturers have when it comes to Industry 4.0 and Industrial IoT solutions. In the rapidly changing manufacturing technology space, it can be difficult to distinguish valuable solutions and approaches from shiny objects and short-term thinking. We’re here to address concerns and provide clarity around these topics to help you move forward with confidence. Explore the complete series:

There’s a constant buzz regarding the latest and greatest technological developments such as AI, IIoT, machine learning, and 5G. But with all of these up-and-coming technologies, determining which offers value and where to start is a daunting task.

Many managers in the manufacturing industry have spent years using legacy software that was supposed to make life easier but instead resulted in siloed data, a lack of interoperability, and stifled innovation. As a result, many managers fear that the new slate of technological goodies are simply shiny objects like the ones they’ve endured already. It doesn’t help that these legacy software companies are now jumping on the IoT bandwagon by offering piecemeal or DIY IoT products.

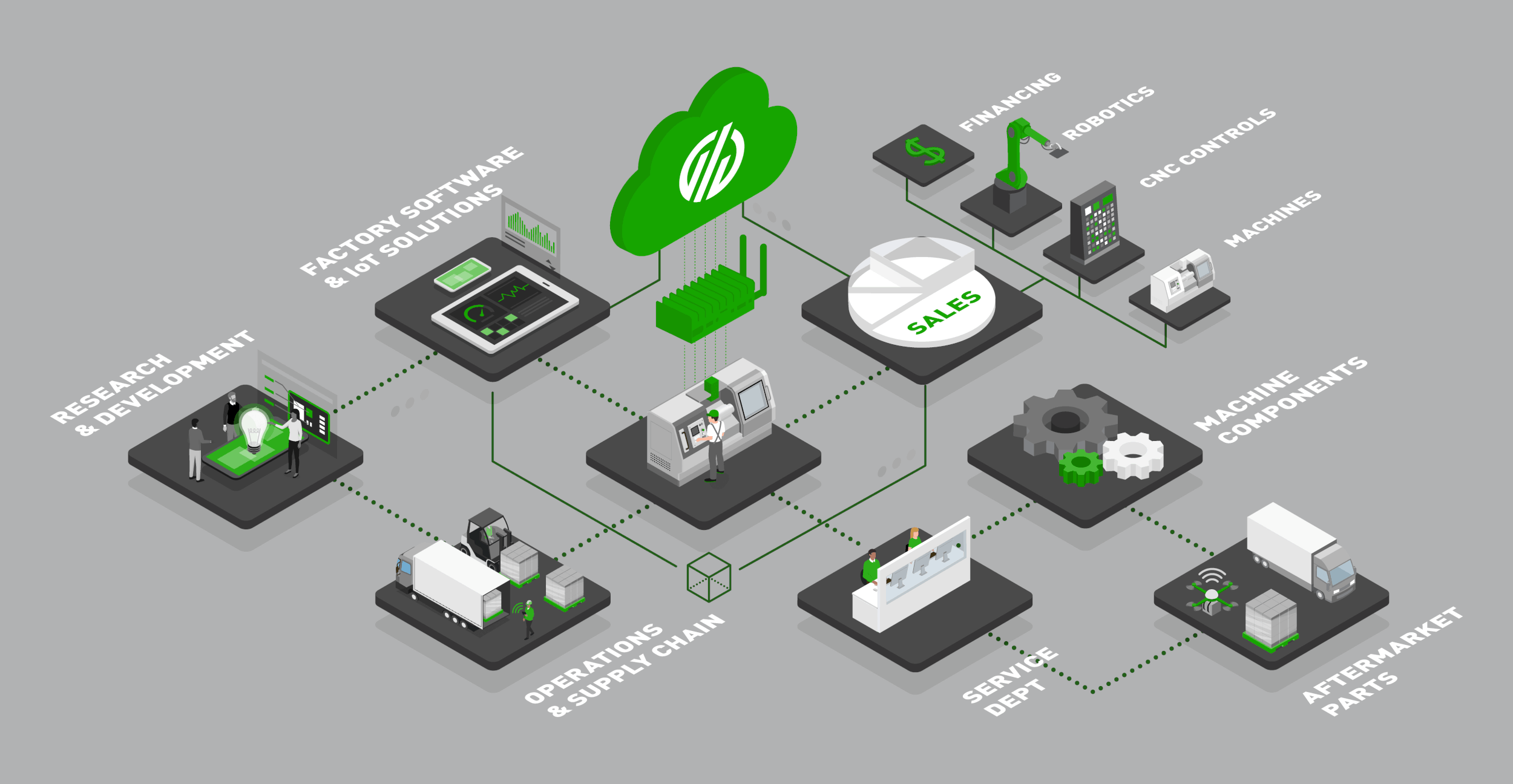

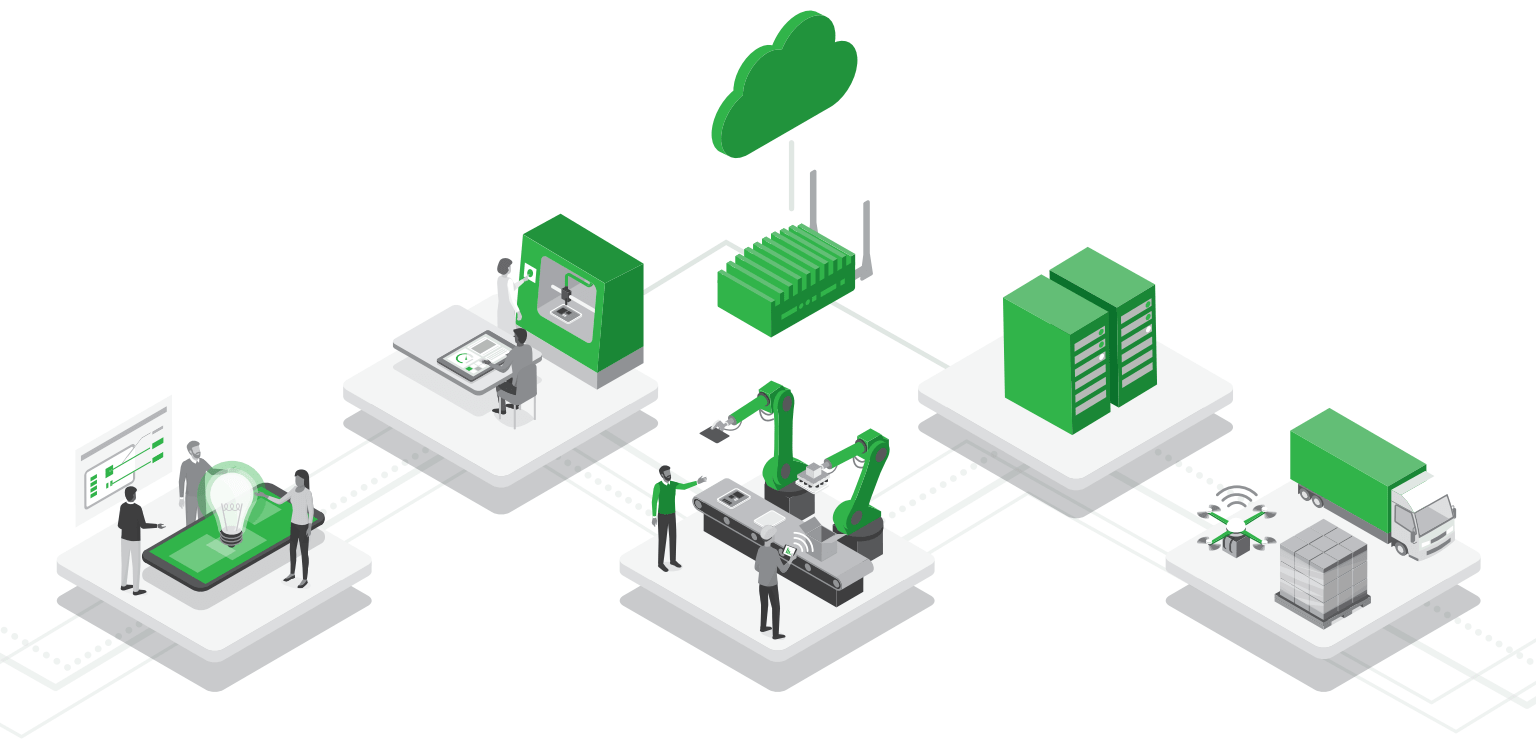

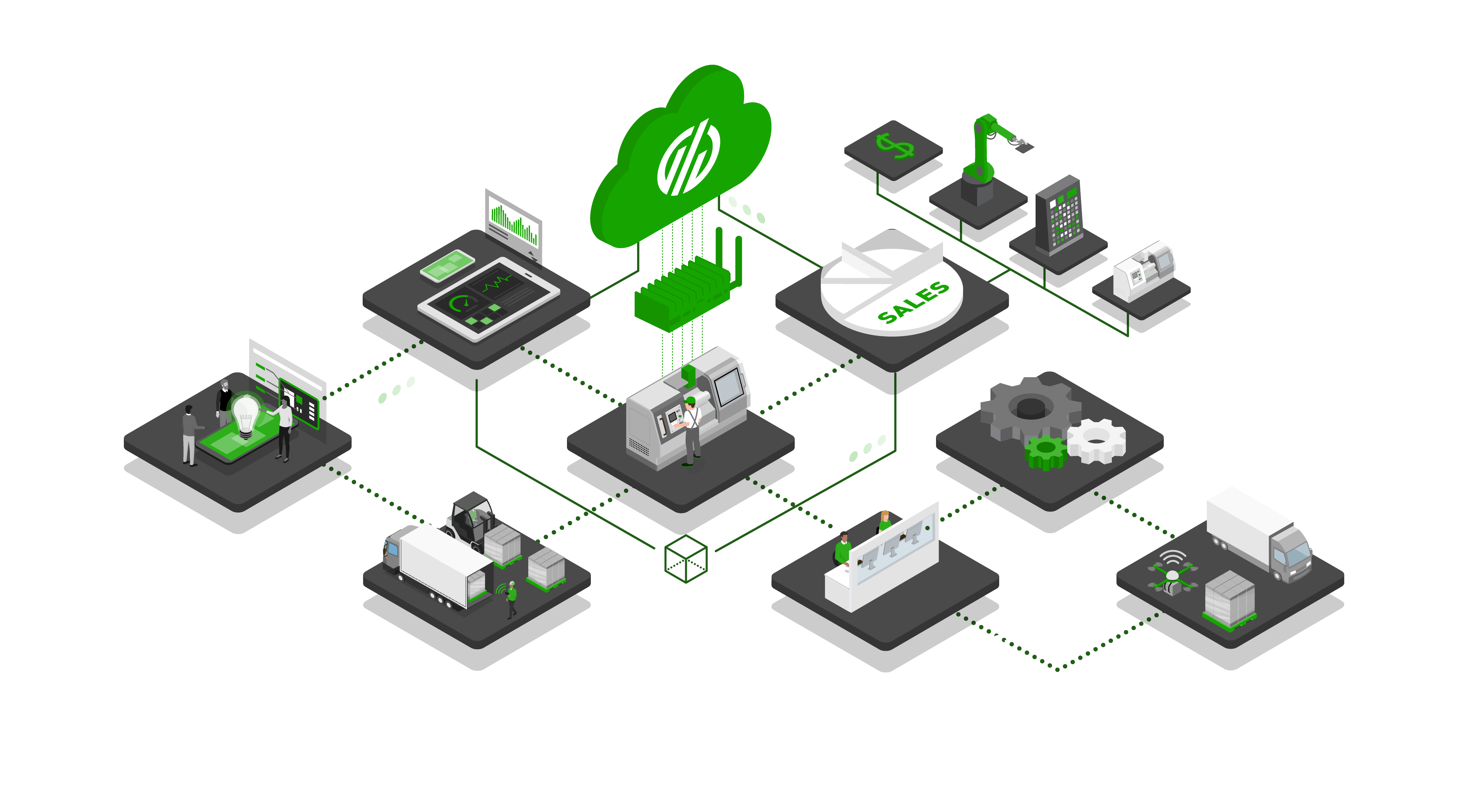

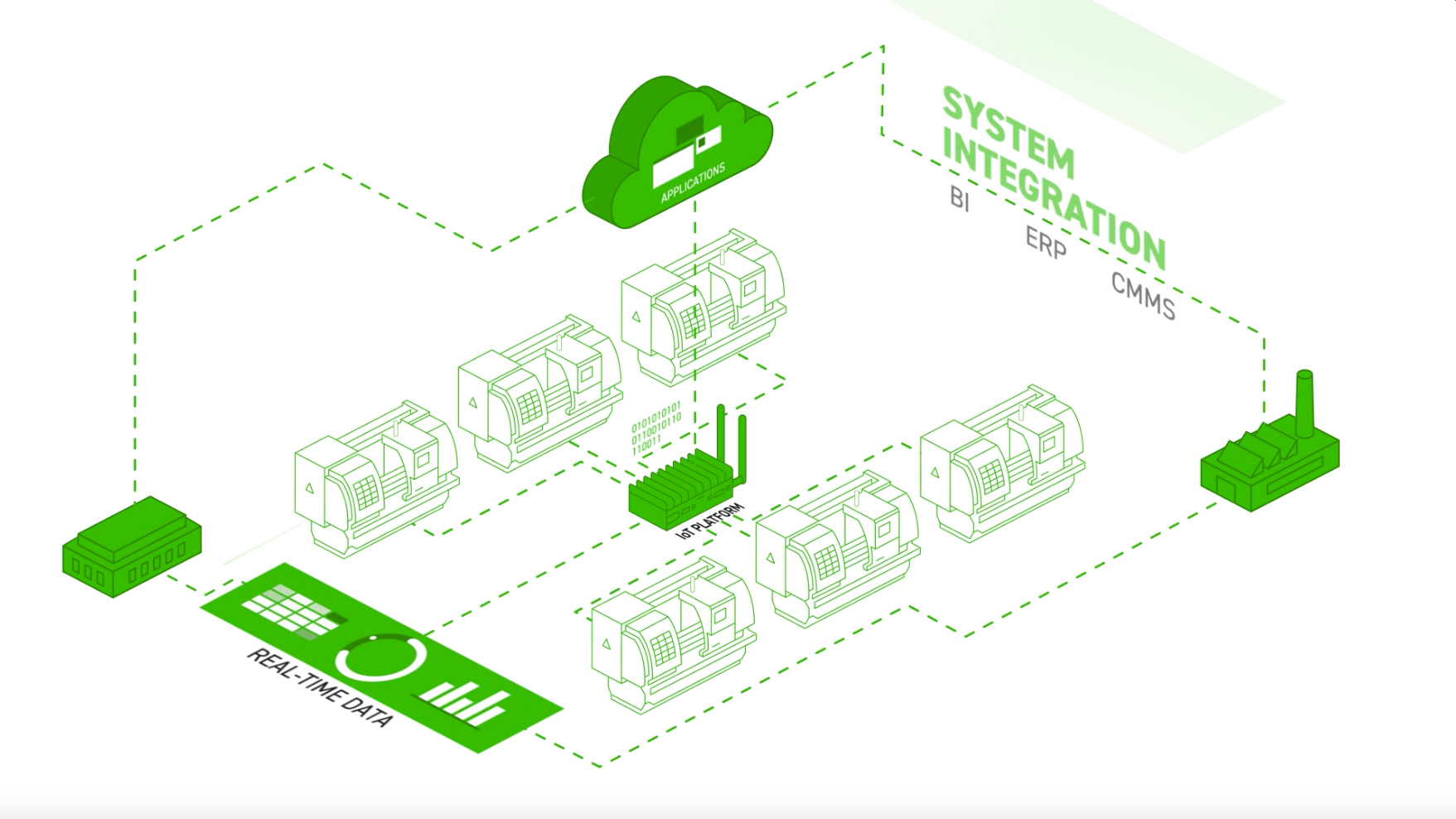

In reality, IoT platforms are much more than just an upgrade to legacy systems. Industrial IoT platforms are designed to manage massive amounts of data and provide the essential connectivity needed to manage a connected factory. These platforms also make it possible to take advantage of the latest technologies like machine learning and artificial intelligence.

You Need an IoT Platform Built for Manufacturing: Here’s Why

The problem with the abovementioned legacy software systems is that they only brought manufacturers part of the way. As factories become increasingly complex with more machines and systems working together to produce products, the need for a comprehensive IoT platform becomes clear.

That’s where IoT platforms such as MachineMetrics come into play.

Performance Isn’t as Good as It Could Be

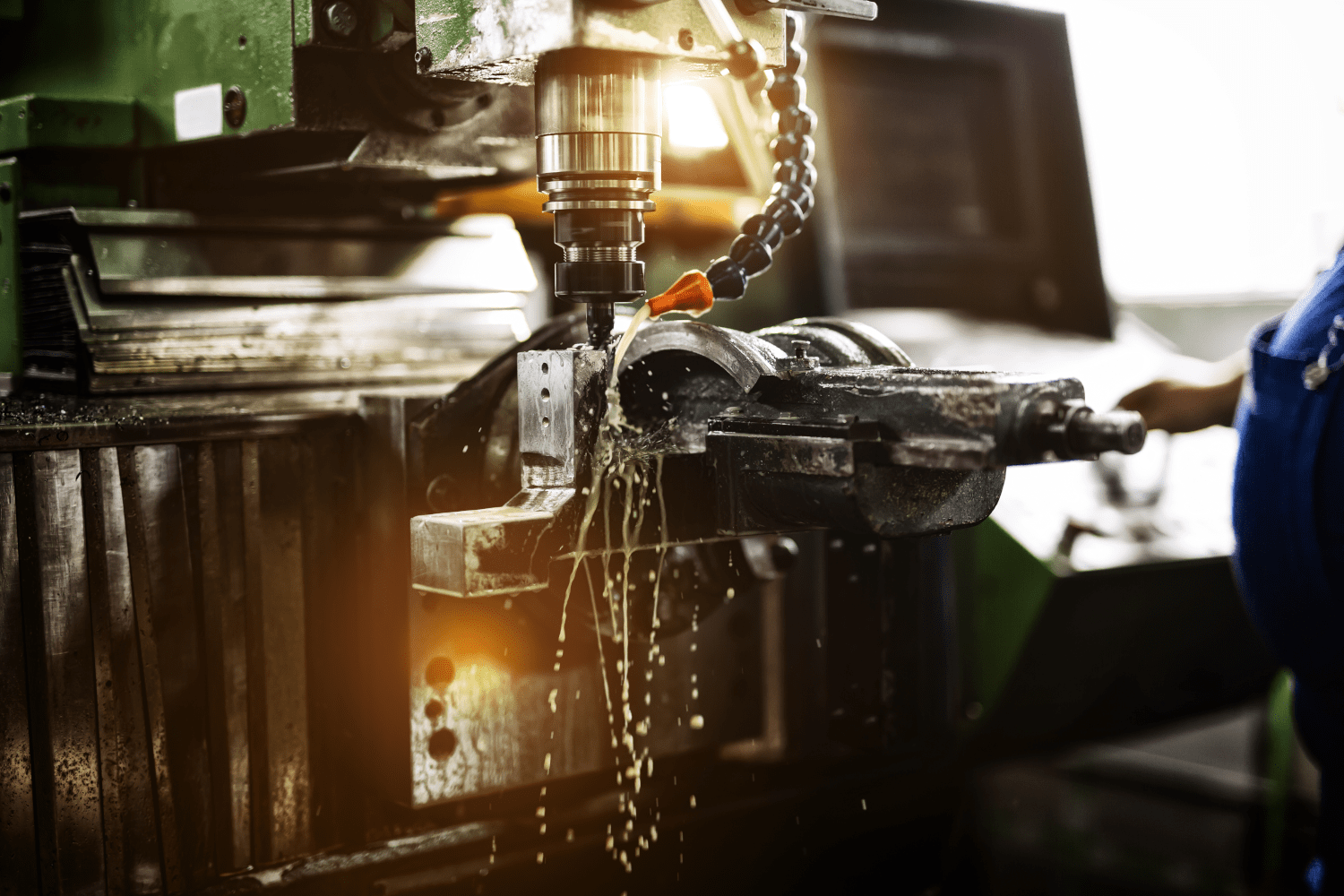

Most manufacturers believe their equipment utilization is much higher than it is. But without automated systems that capture and contextualize machine data directly from the equipment, they can’t confirm what their utilization truly is. Customer case studies by MachineMetrics have shown that most companies average only 28% equipment utilization.

Without real-time data and insights, companies are also stuck with siloed data prone to human input and interpretation errors. On top of that, their legacy software may not fully integrate with other software, meaning they’ll end up spending more time reconciling the outdated numbers they have and less time making improvements.

Manufacturers need a platform that accurately collects production data in real-time. Without it, they’ll lack the visibility and awareness that can lead them to accurate performance expectations.

Manual Data Collection is Inefficient, Inaccurate, and Unscalable

Anyone who’s been around manufacturing long enough knows that manual data collection was once the norm - and continues to be pervasive on the plant floor. But with today’s technology, manual data collection is a terrible misuse of time and resources. Not to mention, it’s also highly inaccurate. Even simple mistakes such as incorrectly entering a number into a spreadsheet can plague a system that’s already slow, siloed, and difficult to reconcile.

Many MachineMetrics customers once painstakingly input data collected by machine operators into their existing IT systems in order to gather insights from the production floor. But tedious hours of data collection, coding, and other manual processes only wasted their time and resources. They eventually realized the need for software to streamline this process and obtain more accurate data.

Plug-and-play Machine Connectivity

Machine Builder IoT and Machine Monitoring Systems Don’t Cut It

There are many machine monitoring systems out there that claim to connect your equipment with yet another layered software system. However, this could just recreate the dilemma that manufacturers already face at the enterprise level - siloed data and a lack of interoperability.

Multiple tools collecting data and presenting it in different formats and contexts only compounds an already complex problem. It results in an independent (and often contradictory) analysis that leads to many companies abandoning the OEM IoT and returning to paper tracking.

Manufacturers who want to leverage the IoT solutions offered by OEMs should be prepared to determine whether the solution can be extended across generations of the same OEM equipment or equipment built by other OEMs.

MachineMetrics offers a versatile solution that works across different OEMs and multiple generations of equipment, including analog legacy equipment, all as part of a plug-and-play solution.

Your ERP/MES Don’t Have to Drive Vendor Selection

ERP/MES solutions are often process-centric. They leave data collection to the manufacturer and cannot collect data themselves. Like an OEM who wants you to invest in only their equipment, ERP/MES systems are proprietary. They want you to buy into a suite of products that may still be limited at the equipment level.

The MachineMetrics platform offers superior extensibility, meaning that both upstream and downstream integrations enable BI, MRP, ERP, and other technology to work with the captured data. MachineMetrics also enables real-time data to be pushed directly to the ERP, supercharging it with seamless integration to let it perform at its full potential.

Building an IoT Solution in House Usually Leads to Pilot Purgatory and Failure

It’s common for companies to build their system using existing infrastructure and in-house IT support. The problem is that most of these companies don’t have in-house expertise in this field and the ones that do are stretched thin from managing and maintaining a host of other systems. This means long hours, increased costs, constant upgrades, and difficulty translating vast amounts of data into consumable information.

These companies often find themselves in a "pilot purgatory," a situation where the project is stalled due to a lack of clarity on how the system should work and who should be responsible for what. As a result, the project can drag with no end in sight.

A company building its own IoT system will likely find it difficult to remain on the cutting edge of technology while simultaneously keeping up with ever-changing business goals.

MachineMetrics succeeds where these homebrew systems fail because our core competency is consumable data right out of the box. We’ve invested our entire team in creating and improving a platform that’s agnostic of equipment age and OEM manufacturer. We can add value by helping companies identify use cases and improve performance without being bogged down by legacy infrastructure or data management issues.

The Case for MachineMetrics

Industrial IoT platforms are a necessity, not a “nice-to-have.” They make it possible for businesses to collect and use data in ways that weren’t possible before, and they help companies keep up with the growing demands of the connected world.

MachineMetrics is an Industrial IoT Platform that offers a foundation for manufacturers’ continuous improvement journey. By collecting accurate, real-time production data, managers have complete operational visibility with out-of-the-box reports and dashboards, notifications, and powerful workflows to optimize and automate processes.

At MachineMetrics, we define IoT as a “must-have” rather than a “nice-to-have.” We’re experts in identifying problems before they occur, improving morale with accurate data-driven communication, uncovering hidden trends that drive improvement, and unlocking additional capacity.

These capabilities deliver immense value to our customers and typically increase their production by over 20% in a matter of months. If you’re ready to enhance your manufacturing operation beyond its current capabilities, contact us today to get started.

Want to See the Platform in Action?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments