Key Takeaways:

- Machine utilization measures how effectively manufacturing equipment is used in production processes.

- High utilization rates indicate efficient use of resources, leading to lower costs and higher output.

- Monitoring and optimizing machine equipment utilization can improve overall productivity and profitability in manufacturing operations.

Manufacturing is a costly endeavor. Labor, raw materials, indirect overhead, and capital equipment are all large cost centers, and optimizing them is a goal of any manufacturing company. But one thing stands out among those costly line items. While all these areas have room for process improvement, utilization rates of machines can make or break all the others.

The scary part: The average manufacturer has a utilization rate of just 28%!

With poor utilization, labor and overhead costs rise. It also impacts raw material in the form of inventory that doesn’t move as fast as it should. And in many cases, it can spur companies to purchase even more expensive equipment to keep up with demand.

Wouldn’t it be better to figure out how more effective equipment utilization would make your machines run more efficiently? Let’s explore how we can make that happen.

What is Machine Utilization?

Machine utilization is a simple measure of the productivity of equipment. It is commonly used in tracking OEE metrics and other KPIs. But what is utilization rate?

The utilization rate is calculated with a machine utilization formula that divides total run hours by the total number of available hours. Available hours constitute the number of hours the machine is scheduled to run and doesn’t include planned idle hours (such as weekends or nights).

The Machine Utilization Formula

Here is a simple and effective machine utilization formula:

(Run Hours / Available Hours) x 100

Also said as:

(Productive Machine Hours / Scheduled Machine Hours) x 100

Below are a few examples of how to calculate utilization rates.

If a machine in a single-shift CNC facility is scheduled to run eight hours a day, Monday through Friday, and due to setups, cleaning, breakdowns, and other operating tasks, only runs for a total of 30 hours, the utilization rate would be 75%.

30 Run Hours/40 Available Hours x 100 = 71% Utilization

In another scenario, in a 24/7 facility, the equipment would be scheduled with no idle hours, and the total available hours would be 168. If the machine runs 85 hours, the utilization rate would be 51%.

85 Run Hours/168 Available Hours x 100 = 51% utilization

This formula shows you how to calculate machine utilization. Now, you must find the optimum rate for the best equipment utilization.

Finding the Optimum Machine Utilization Rate

Not only is every industry different, but every company within those industries is unique, too. CNC machine shops making high-volume parts for a consumer product with lower safety requirements will run with higher equipment utilization than a CNC machine company making bespoke parts for aviation or making one-part lots for complex, high-tolerance jobs.

The key to finding the optimum rate is knowing your industry and applications while having a firm grip on the standards and variables for each machine and part in-house.

But this requires companies to know these numbers and track them accurately. It also requires a data collection system that is free from errors and bias. This is the challenge faced by companies still tracking production data manually. If the data is unreliable or in error, the utilization will be, too.

That means you’ll be making decisions based on faulty assumptions.

Tracking Machine Utilization with Accurate, Real-Time Data

Knowing your industry and market is only part of the solution. Today’s manufacturing environment moves fast and is hyper-competitive. Companies are turning to machine monitoring solutions to gain control of their data with almost endless applications such as OEE software that measures utilization and other OEE metrics. These companies put real-time data to use in understanding utilization of machines, and make improvements based on the insights derived from the data.

Plug-and-play Machine Connectivity

With MachineMetrics, a production monitoring platform, connecting equipment to get the data flowing is easy. The platform easily connects to any make or model of equipment, ensuring both digital and analog legacy assets are connected.

Most importantly, MachineMetrics standardizes the data into a common model. This ensures the data is ready for actionability, driving visibility with dashboards on the shop floor, pushing automated notifications, monitoring OEE metrics and other critical KPIs, and running workflows to manage shop floor processes. For example, Wiscon Products, a precision parts manufacturer, was able to increase utilization by 30% using machine monitoring.

With accurate, real-time data in hand, a company can benchmark itself to understand the true performance of the operation. Many companies are stunned when the returned data shows them a significantly different picture than what they had assumed was their performance rate.

When using MachineMetrics to benchmark yourself, gaps in performance become immediately visible, and managers can begin to take action to improve utilization. Real-time decision-making also becomes possible. Cycle time, breakdowns, scrap outs, and other information inform managers and operators of what steps to take to reduce downtime and increase run time.

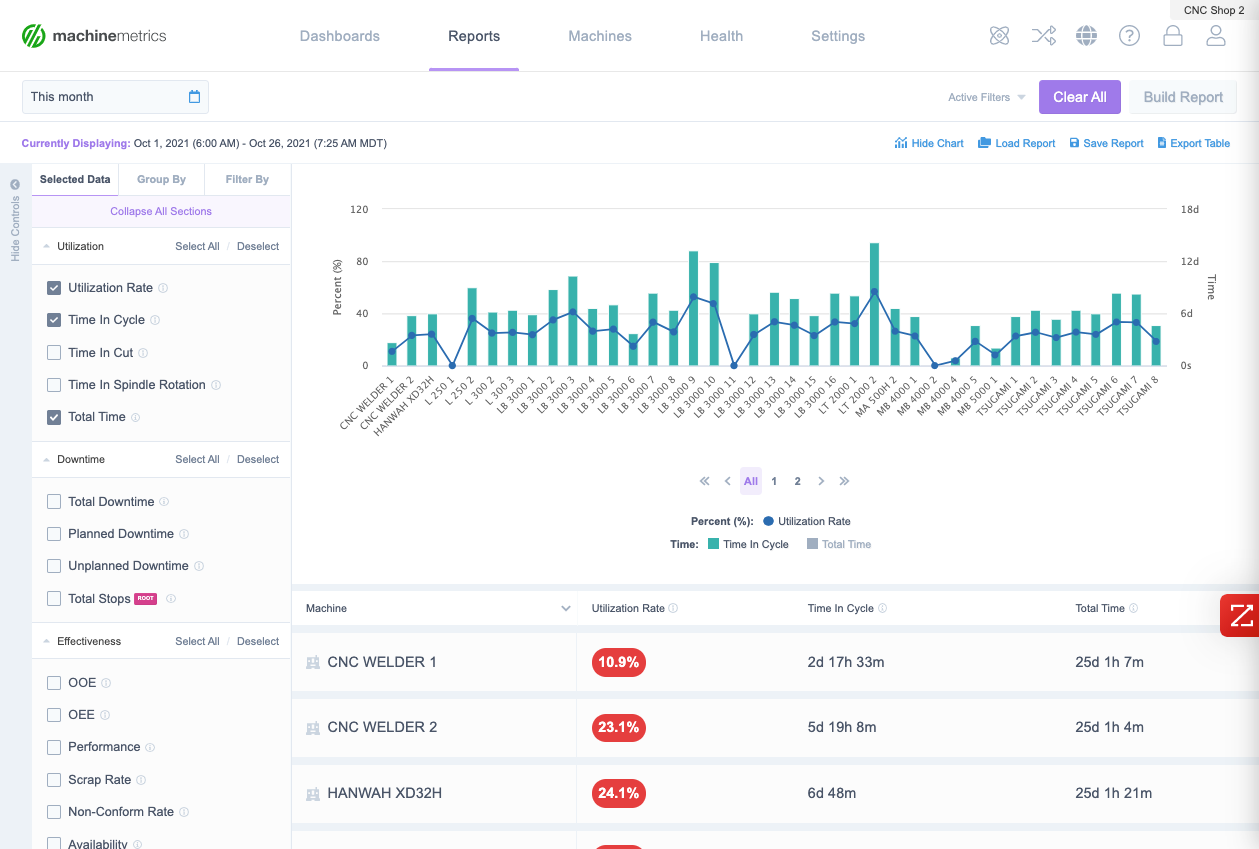

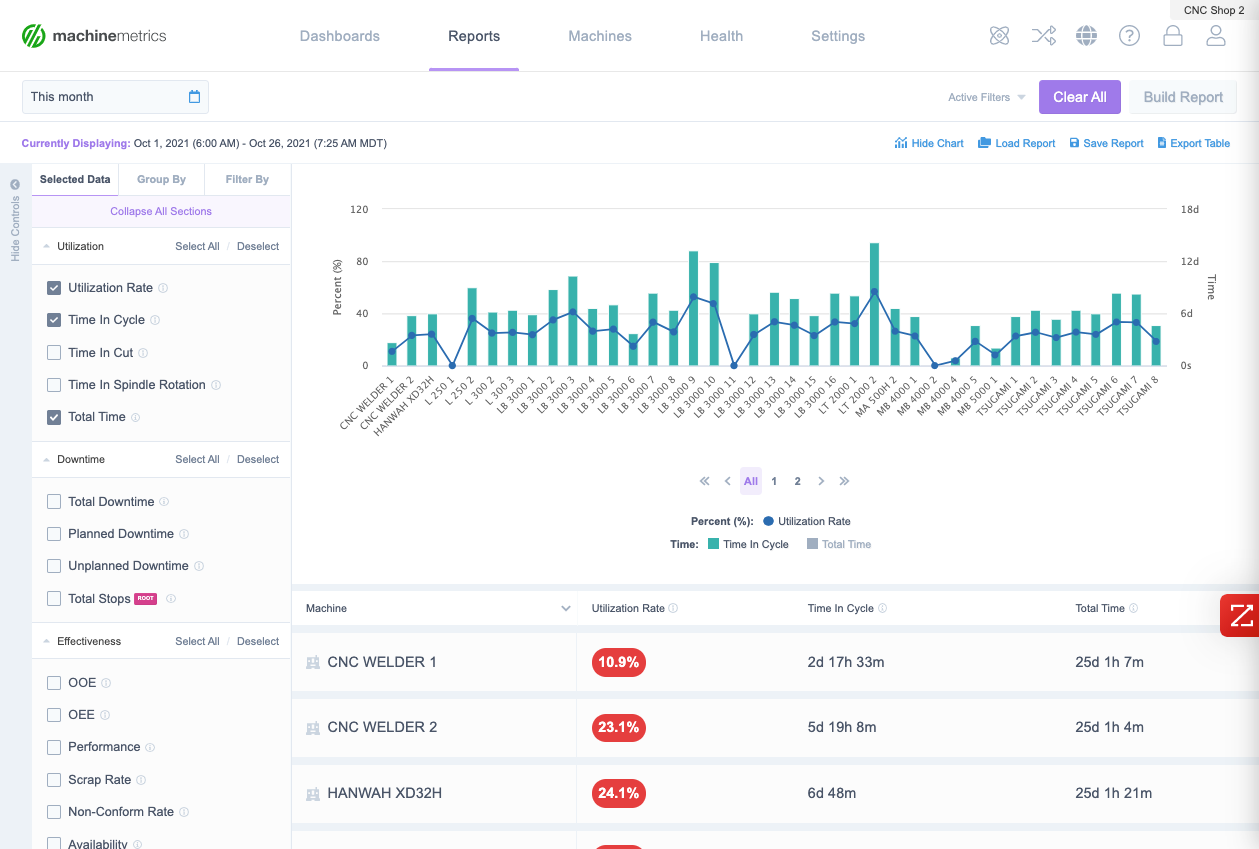

MachineMetrics’ Utilization Report breaks down data even further to capture different visualizations of what is happening at the machine level:

- In-Cycle: The percent of production time reported as “in-cycle.”

- Spindle-Rotating: The percent of time the spindle is rotating.

- In-Cut: The percentage of time the machine is cutting.

All these views and more are unlocked when machine data is used to tell the story.

MachineMetrics helps to not only identify your actual utilization but also pinpoint areas for improvement, such as process bottlenecks and downtime reasons.

MachineMetrics helps to not only identify your actual utilization but also pinpoint areas for improvement, such as process bottlenecks and downtime reasons.

Advantages of Higher Utilization

With control over data and actionable insights that reduce downtime and improve decision-making, many advantages come with higher machine utilization. These include:

- Reduced Capex Cost: By increasing the utilization of existing equipment, many companies have reduced and eliminated new capital purchases because of the amount of capacity that data unlocks.

- Better Supply Chain Management: If materials are moved throughout the manufacturing process faster, cash flow is improved. Holding costs and WIP handling are lower as raw material management is leaner.

- Higher Efficiency: Of course, more run time means higher efficiency. Managers know what is happening (and why) so they can focus on additional improvement methods to address the “why” of downtime and increase efficiency over time.

- Efficient Use of Overhead: Indirect overhead in times of low utilization means idle workers, redundant tasks, and lots of manual expediting to find out where gaps are. With higher utilization, the overhead function is more efficient and spends less time expediting and updating delivery times and order progress.

- Better Service Level Performance: Service levels are improved when the time between jobs is reduced. Lead time reduction can result in higher repeat orders and greater brand loyalty.

Using Data to Improve Utilization

MachineMetrics is fully automated and lets you visualize real-time production data on your shop floor. Be notified instantly of problems and use historical analysis and newly revealed trends to improve uptime and create great utilization rates.

Leverage utilization reports to spot issues at the operator, machine, cell, or plant level and drill in to understand what's causing the problem. With an accurate, real-time measure of shop floor performance, you can easily spot opportunities to increase OEE.

Want to see it in action? Book some time with our team today.

Start Increasing Machine Utilization

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

.gif)

Comments