With each generation of manufacturing, advances have taken place in the form of process adjustments, continuous improvement initiatives, and programs such as Lean and Six Sigma.

Operators, line supervisors, and senior managers can successfully implement these methodologies to improve efficiency, reduce waste, increase quality, and lower costs. However, most companies continue to struggle with eliminating unseen forms of waste due to a lack of visibility into shop floor performance and processes.

With lean programs and a continuous improvement mindset, managers can tirelessly discover where many of their problems exist. But, to truly exploit the hidden capacity on a shop floor, managers need accurate production data that can reveal the Hidden Factory.

We cover a lot in this article, here is an index if you would like to jump to a specific section:

What is the Hidden Factory?

The Hidden Factory is a concept that refers to the unseen, or hidden, parts of a manufacturing process that result in quality issues or decrease the efficiency of the operation.

What's causing this? It depends on the operation at hand, but typically it is due to the difficulty of measuring and accounting for costs associated with certain parts of a process.

For example, it may be easy to track the number of parts created, but it may be more difficult and less accurate to track cycle times. This could result in poor estimates, reduced production goals, and ultimately unseen waste.

Some history on this concept...

First coined in the 1970s, the concept of a hidden factory initially focused on quality. Manufacturers realized that hidden costs were often found in the reworking of parts by operators or a lack of reporting quality data. Thus, the concept of the hidden factory was born.

Over the years, the term has come to encompass more than just quality control within the manufacturing environment. The term "hidden factory" consists of many areas where capacity is locked up in processes related to waste in all production phases, including bad work, broken processes, customer service, inventory, and quality.

Today, the hidden factory concept focuses on losses that cover several categories: schedule loss, availability loss, performance loss, and quality loss. Manufacturers can unlock capacity, productivity, and efficiency gains by understanding how automation, data collection, and analysis can be deployed to reveal this "hidden factory" within your operation.

Why is Exposing the Hidden Factory Important?

Recognizing the hidden factory is crucial for manufacturers because it can account for a significant amount of all losses. These losses represent capacity that isn’t being used to produce goods.

Examples of waste that results in hidden quality include:

- Lack of document control leading to multiple versions or an outdated version of a specification

- Lag time in data reporting

- Rework that ties up labor

- Miscalculated cycle time

- Lack of SOPs that result in a changing cycle time creating low production or hidden part damage

- Costs caused by poor or misunderstood preventative maintenance requirements

Ignoring the hidden factory in your organization can result in loss of profitability as these wastes draw down resources allocated to the factory floor. It also diverts capital to new equipment that may not be needed, taking working capital away from things that could be deployed to improve processes and grow the business.

Any example like the ones above will result in rising costs across the board. When line supervisors and senior management don’t know what percentage of capacity is tied up, they may operate with a false performance illusion, not realizing the hidden factory underneath.

The True Cost of the Hidden Factory

Silo Mentality

In manufacturing companies with manual data entry and management, the organization is likely to develop a silo mentality. Because data is both limited and locked within different departments and systems, communication is spotty and inefficient.

This forces teams to make decisions based on inaccurate or missing data, which is likely to result in unforeseen waste, poor quality, and inefficiencies.

Feedback Loop

This process of siloed data repeats itself to the next level through to senior management. Information and guidance are pushed back down through the silo, creating a feedback loop.

Because the data was unreliable or incomplete, instructions may not make sense and expectations may be misaligned with reality. Processes that could be identified as problematic are ignored or not noticed, and the process repeats itself in a virtuous cycle.

Unclear Costs

When manufacturing managers don’t know what capacity is locked up, they won't understand the actual costs of waste and losses. As the hidden factory can account for 20-40% of all capacity, these unknown costs can’t be turned into productivity and efficiency to service more customers and grow the business.

The Benefits of Discovering the Hidden Factory

Understanding the reality of the hidden factory has many advantages. It can unlock capacity, improve customer satisfaction, reduce labor and material costs, and many other benefits, including:

Improved Equipment ROI

Capital expenditure costs are one of the most expensive undertakings for manufacturers. If capacity is hidden, a company may be forced to spend additional money on a piece of equipment to increase production. Suppose it’s unlocked through Lean, Six Sigma, Lean Six Sigma and combined with a robust digital transformation that changes the whole process. In that case, companies may realize that the equipment they needed was right under their noses, eliminating the need for the new purchase and increasing the ROI on the old.

|

Case Study: Learn how Continuous Improvement Manager Denis Mursoi of Morgan Olson saved $600,000 in capital expenditures by identifying hidden capacity on the shop floor: Morgan Olson Reveals Their Hidden Factory

|

Happier Customers

Unlocking the hidden factory makes for happier customers. Manufacturers can produce goods faster, shortening lead time and making goods at lower costs overall. Unlocking higher capacity through the hidden factory also allows companies to introduce more products, so customers have a wider selection of products to choose from.

Enhanced Competitiveness

If one manufacturer in an industry suffers from the hidden factory in their operation, it’s a good bet that others do too. By unlocking capacity, companies can get a jump on the competition by doing more with less. This makes them the low-cost producer and increases their agility to respond to disruptions and deliver more value.

Greater Process Improvement

Lean and Six Sigma are fantastic methodologies that have delivered unprecedented value in the last few decades. They’ve helped improve processes and lower costs. But many of these initiatives were implemented with a company’s hidden factory still layered underneath.

Helpful Read: 5 Lean Techniques that Will Improve Your Manufacturing Processes

Unlocking an organization's total capacity through a digital transformation using automation and IIoT factory monitoring platforms allows Lean and Six Sigma programs to dig deeper. With real-time, accurate data, these methodologies provide structure and process gains in manufacturing when the hidden factory is revealed.

Unsiloed Data

Siloed data, reporting, and processing are eliminated with discovering the hidden factory. With new capacity at their fingertips and accurate data in hand provided by a machine data platform, managers can easily allocate resources accordingly. This can increase value through producing accurate KPIs, understanding actual costs, and creating greater collaboration between departments.

How to Reveal (and Exploit) the Hidden Factory

Surfacing the Data

The hidden factory lies just beyond the existing way in which your business is measured. The problem is that in many cases the information reviewed to understand the performance of the shop floor is highly inaccurate. From inaccurate cycle times, poorly developed work standards, to flawed performance benchmarks based on incorrect assumptions.

Without accurate production data, managers simply cannot hope to find the hidden waste on the shop floor. While strict manual data collection methods can take job shops to a certain degree, the sophisticated manufacturer is leveraging solutions that collect, aggregate, and standardize production data autonomously. With this data in hand, accurate benchmarks can be set (they may be quite surprising) and areas of hidden capacity, as well as waste-generators, can be far more easily identified.

MachineMetrics is a machine data platform that autonomously collects and standardizes data from all makes and models of equipment, enabling actionable insights and automation. With visible production data, you can easily spot waste generators and additional capacity waiting to be unlocked.

Calculate Rolled Throughput Yield

One excellent tool for identifying the hidden factory is Six Sigma’s Rolled Throughput Yield (RTY), which is a calculation that shows what your yield is for all products. Knowing this helps you zero in on the worst process performance to develop strategies for continuous improvement. The first step is to identify the Defects Per Unit. This calculation is a simple expression of DPU=D/U.

The formula then determines the yield by using a mathematical constant of e, equal to 2.718 and expressed as e=2.718-DPU.

Finally, the RTY is calculated as a percentage of multiplying all yields for all processes. For example, if you have the following yields of 0.90, 0.91, 0.99, 0.98, and 0.97, the yield would be 0.77, or 77%.

Waste Generators

Once you know your yield, you can focus on specific processes to identify the poorest performer. These can be classified within which category of the waste generation belongs to a group of like performers. Types of waste generators include:

- Waiting (Delays)

- Process Workarounds

- Non-Value-Added Work

- Plant Layout

- Inventory Errors

- Training

- Defective Products

- Over-Processing

- Quality Fallout

By mapping out RTY and classifying which waste generator it belongs to, teams can group them to address a specific waste category process rather than tackling each poor yield one at a time. Machine monitoring can be an effective solution for identifying the types of waste your operation is experiencing.

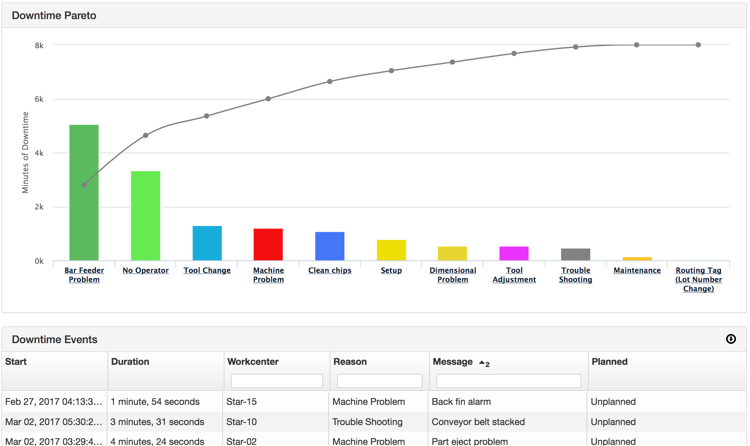

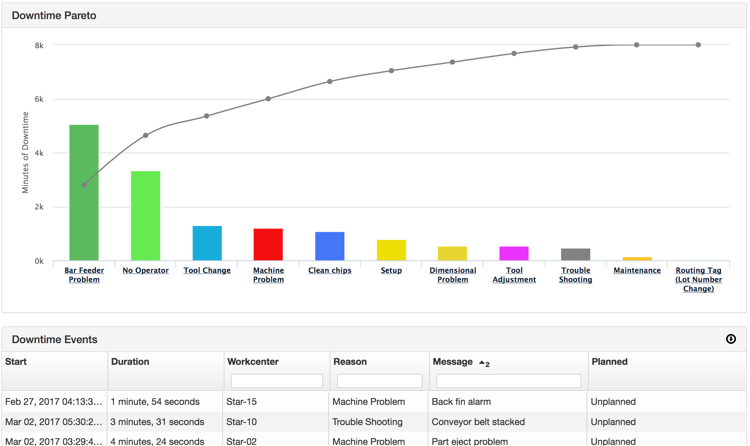

Easily collect data and report on downtime, quality, and waste with intuitive dashboards from MachineMetrics.

Easily collect data and report on downtime, quality, and waste with intuitive dashboards from MachineMetrics.

Running a Capacity Analysis

Once accurate machine and production data is collected, hidden capacity can be found using a capacity analysis. For brevity, here is a quick summation. For greater depth, read our article: How to Perform a Manufacturing Capacity Analysis.

Benchmark Data: Benchmarking includes determining existing capacity. Machine speed, quality losses, downtime by categories – such as breakdowns, changeovers, and performance losses – must all be measured to determine the current capacity.

Analyze Downtime: Once a manufacturing operation has benchmarked its data and understands its true utilization, a downtime analysis must be conducted. By answering how much downtime is occurring and what category the downtime falls under, steps for improvement become more apparent.

Rollout Process Changes: Managers are now equipped with accurate and verifiable data that drives real change at this point in the capacity analysis. These changes can be used to tackle the most significant capacity constraints, unlock the hidden capacity to eliminate overtime, reduce the need for capital expenditure, and hone a maintenance program that works in sync with changeovers and other operating conditions instead of contention with them.

Managing Transaction Overhead

Businesses that have never utilized Lean or Six Sigma methodology or initiated process improvement based on designing an industrial IoT system are almost guaranteed to have a high transaction overhead.

Many poor processes are transaction-driven, meaning that recording, calculating, and rationalizing steps must be taken to move the process forward. Many of these may be redundant, while others are ideal for automation. Managing transaction overhead is crucial to identifying elements to unlock the hidden factory.

The Hidden Factory and Digital Transformation

The concept of unlocking the hidden factory is an exciting and challenging journey. It's certainly one that will challenge your continuous improvement mindset as you continue to reduce waste and inefficiencies.

Unlocking the hidden factory should go side by side with digital transformation. Data gathered by connected equipment with edge devices and IoT sensors deliver incredible value by providing a source of real-time, accurate information with which to search for areas of concern.

The changes made along the way are immediately measurable in real-time when done in conjunction with digital transformation. Managers can spend more time on the front end of the project implementing process improvement because they can access the data faster and more accurately.

Find the Hidden Factory with MachineMetrics

Frequently Asked Questions

There are many questions and concerns when it comes to the hidden factory. Below, we’ll address some of the most common ones.

1. What are the Effects of the Hidden Factory?

In most organizations, the hidden factory keeps a significant amount of capacity out of production. It forces companies to buy equipment they don’t need and reduces ROI on additional equipment. It sticks to the status quo to leave quality issues and poorly performing processes in place.

2. How Does the Use of RTY Affect the Hidden Factory?

RTY accounts for the yield of all processes or sub-processes, helping to identify areas where action should be taken first.

3. How Can you Identify a Hidden Factory?

Companies with a hidden factory often have siloed data, manual processes, lack of collaboration, high-quality fallout, and lower value per unit produced.

4. How Much Does the Hidden Factory Cost?

It’s estimated that about 20-40% of a manufacturing company’s capacity is hidden. This constrained capacity is a high cost in terms of money expended and unattained profit.

5. How Does a Company Discover the Mysteries of the Hidden Factory?

The best path for uncovering the factors causing a hidden factory and putting it to work for your company is digital transformation and effective use of Lean and Six Sigma methodologies. But that’s not all. Today, uncovering your hidden factory and putting it to work can deliver even greater rewards.

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments