Big data and manufacturing go hand in hand because so much of what goes on in a manufacturing business is measurable and able to be optimized. Data streams are increasing in size, relevance, and number as most manufacturers flock to the powerful capabilities, predictions, and insights that shop floor data can unlock for their businesses.

But the true value of data can only be accessed if manufacturers can successfully develop a culture and deploy an infrastructure that supports the automated real-time collection of manufacturing shop floor data. They’ll be able to experience rapid value creation and immediately improve productivity. They’ll also enable even more advanced use cases based on higher volumes of data, more data sources, and automation.

Why Is Collecting Data So Important For Manufacturers?

In a word: visibility. By using manufacturing data collection software to collect shop floor data, manufacturers are better able to measure, understand, and optimize production. With the right shop floor data in front of them, to make decisions that are rooted in fact. This is why it's incredibly important to have accurate, real-time production data democratized for all stakeholders.

- Operators can use interfaces at machines that display machine statuses, part counts, or other KPIs to ensure they’re meeting production goals.

- Plant Managers can use visible production dashboards to see where operators need support or when machines are down.

- Engineers can use aggregated shop floor data to spot bottlenecks and tweak processes accordingly.

This is all part of a journey of advancement for manufacturers. As they become more "data-mature," they can begin to drive even more advanced use cases with their data beyond simple data collection and visibility. We call this the "manufacturing analytics journey" and explore it further in a comprehensive eBook on manufacturing analytics.

Because so many manufacturers still don’t collect data (or only use manual systems), deploying solutions that allow you to monitor and collect manufacturing shop floor data in real-time is a major competitive advantage. Not only can this help win customers over, but it also creates a leaner operation rooted in effective data-driven decision-making.

Plug-and-play Machine Connectivity

The Benefits of Manufacturing Data Collection

The benefits of shop floor data collection are multi-faceted for modern manufacturers. Although not an exhaustive list by any means, adopters of data-driven strategies can see benefits in the form of:

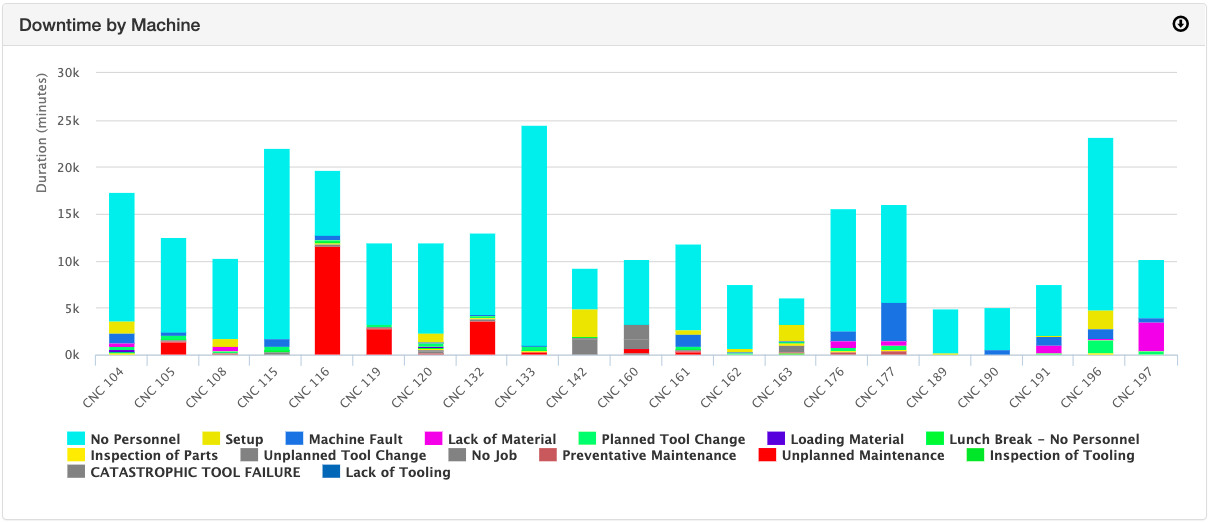

- Significant reduction in downtime by understanding and mitigating the most egregious downtime reasons with immediate feedback.

- Optimizing efficiency and productivity on the factory floor by reducing production bottlenecks.

- A stronger maintenance program based on real-time notifications and machine conditions.

- Cost reduction for supply chain with more accurate demand forecasting, supplier scoring, waste reduction, and warehouse optimization.

- Higher quality products that better align with customers’ wants and needs based on how products are used in a real-world scenario.

| Using Data to Drive Efficiency: Learn how Mayville Engineering, a contract manufacturer, leveraged production data to drive a bottom line impact, increasing their uptime by 15% and efficiency by 20%. Read the full story. |

Do You Require Shop Floor Data Collection for Production Tracking?

Without shop data collection and shop data input, there would be no production tracking. A cumulative piece count of first quality pieces or other broad stand-alone aggregate numbers doesn’t constitute production tracking. The data must have enough data points to analyze the rate of production, efficiency, overtime and shift differentials, maintenance costs, etc.

And that analysis must be able to look at the workflow of orders across the shop floor at the holistic level. Even if it is manually collected, data entry errors are common. Accurate data is essential to track production if the goal is process improvement, efficiency, or cost savings. Types of data collection for production tracking may include:

- Downtime: Downtime for jams, cleaning, minor slowdowns, stoppages, and other reasons can be recorded by operators or tracked using production tracking software. In the case of the latter, the accuracy of downtime is optimized - eliminating rounding, human errors, or forgotten downtime events. The software also allows for the categorization of types of stops.

- Changeovers: Changeovers too can be manually recorded. But changeovers monitored by tracking software are excellent analysis points that significantly reduce changeover time for new setups.

- Maintenance Breakdowns: Like categorizing downtime, the software helps track the types of maintenance breakdowns, service orders, and their potential causes. This may lower costs and allow companies to establish predictive or prescriptive maintenance based on accurate real-time data.

- First Quality Pieces: A basic element of production tracking. Without knowing what’s produced first quality, companies can’t know where they’re at with fulfilling orders for delivery within quoted timeframes. Production tracking with software ensures these counts are accurate and orders are filled correctly.

- Scrap: Waste is a large concern for manufacturers. But manual systems will miss scrap pieces or document the wrong reasons. Production tracking software can track the number and type of defects so that analysis can be done to pursue improvement. It can also capture rework, rework time, and associated tasks.

- WIP Inventory: Inventory accuracy is paramount in manufacturing, but a lot of material may be “invisible” once issued to the floor. Production tracking data collection for the movement and status of WIP is important in understanding overall efficiency.

- Performance to Schedule: Accurate data collection is required for production tracking to understand where production orders are in relation to their scheduled run times and analyze job progression. If ran out of order, customer requests may not be completed within the quoted lead time. Shop floor data collection offers a detailed production history and helps managers keep production on track to meet established delivery times.

Shop floor data collection is essential for production tracking. Manual data entry is possible, but there are severe drawbacks, including human error, data entry errors bias, and lack of reliance on real-time. A shop floor insight makes for better decision-making. Production tracking software uses real-time data collection and powerful analytics to look at the production system and eliminate these drawbacks.

Techniques for Collecting Data from the Shop Floor

With so many potential data sources, manufacturers often use a variety of data collection techniques. Some of these include:

- IoT (Internet of Things) sensor integration is used for connecting different equipment and systems to get the right information to the right people at the right time with the right shop floor insight.

- PLC (Programmable Logic Controller) integration is for measuring and controlling steps in the production process.

- Line HMI (Human Machine Interface) system integration (such as individual shop terminals like touch screens mounted on factory floor equipment) allows for the addition of human context to data.

- SCADA (Supervisory Control and Data Acquisition) systems to control operations in an overarching sense.

- CNC and other machine integration (new and legacy models) to track machine production performance and health.

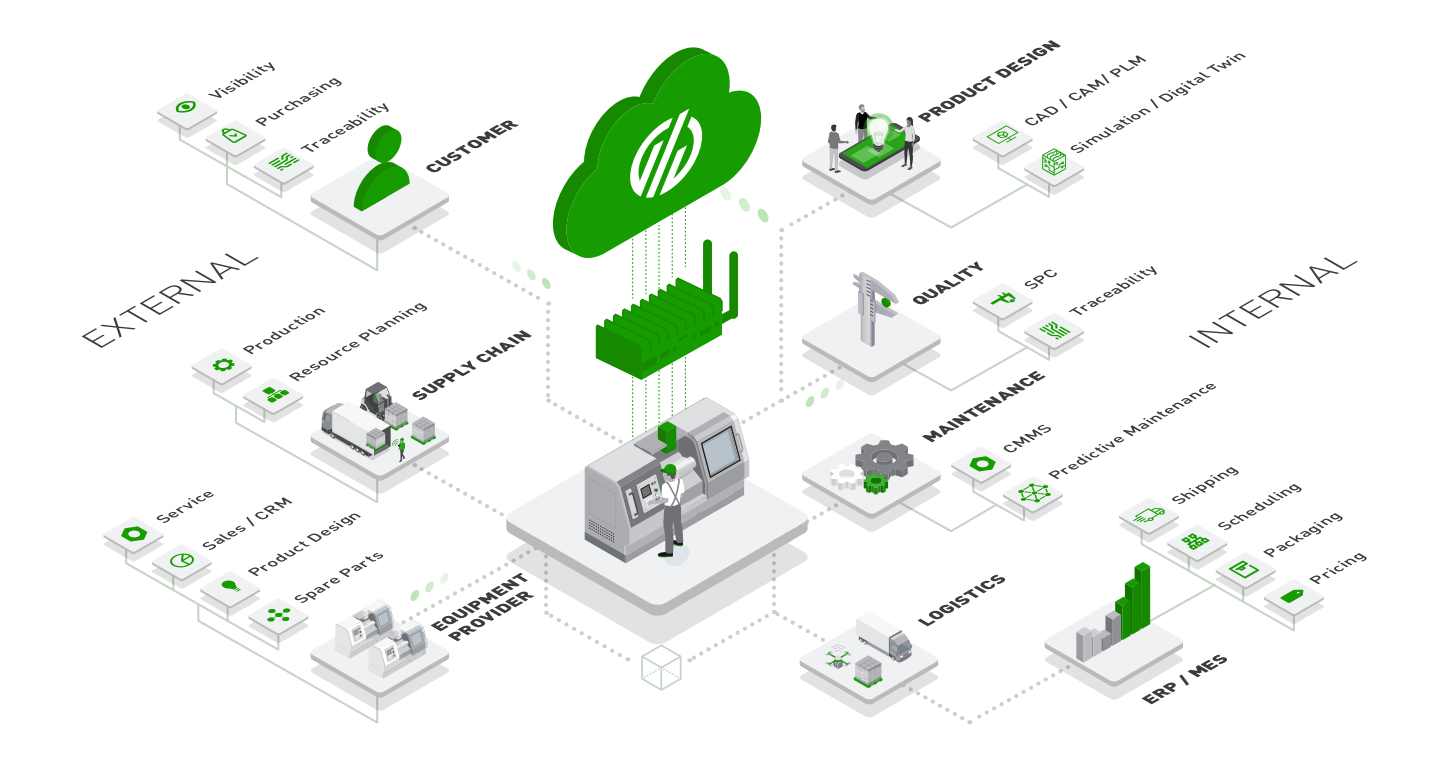

The MachineMetrics Approach

MachineMetrics utilizes many different methodologies for shop floor data collection from machines. How we go about accurate data collection is entirely dependent on the unique features and limitations of each machine on a shop floor. Age, control, make, and model all factor into a machine’s capabilities and shop floor performance.

We consider the information from the control of the machine to be the best source of production data in delivering a shop floor insight. Still, we also realize the importance of human context. Machine data alone can’t tell the full story of production performance, so we layer on data from operators logged via a tablet interface at each machine.

Want to See the Platform in Action?

This gives operators and managers a clearer picture of production performance. Not only will they know the amount of downtime experienced, but they’ll know the reason why machines were down.

Not only will there be an accurate scrap rate benchmarked, but they’ll know the common reasons for scrap parts. They’ll also eliminate extremely tedious tasks, improve the performance of valuable fixed assets, and realize a higher ROI with a cost-effective rollout.

This added layer of operational data provides a comprehensive solution. It gives manufacturing leaders the additional shop floor insight data to tweak processes, eliminate non-productive activities, and make decisions that positively impact productivity.

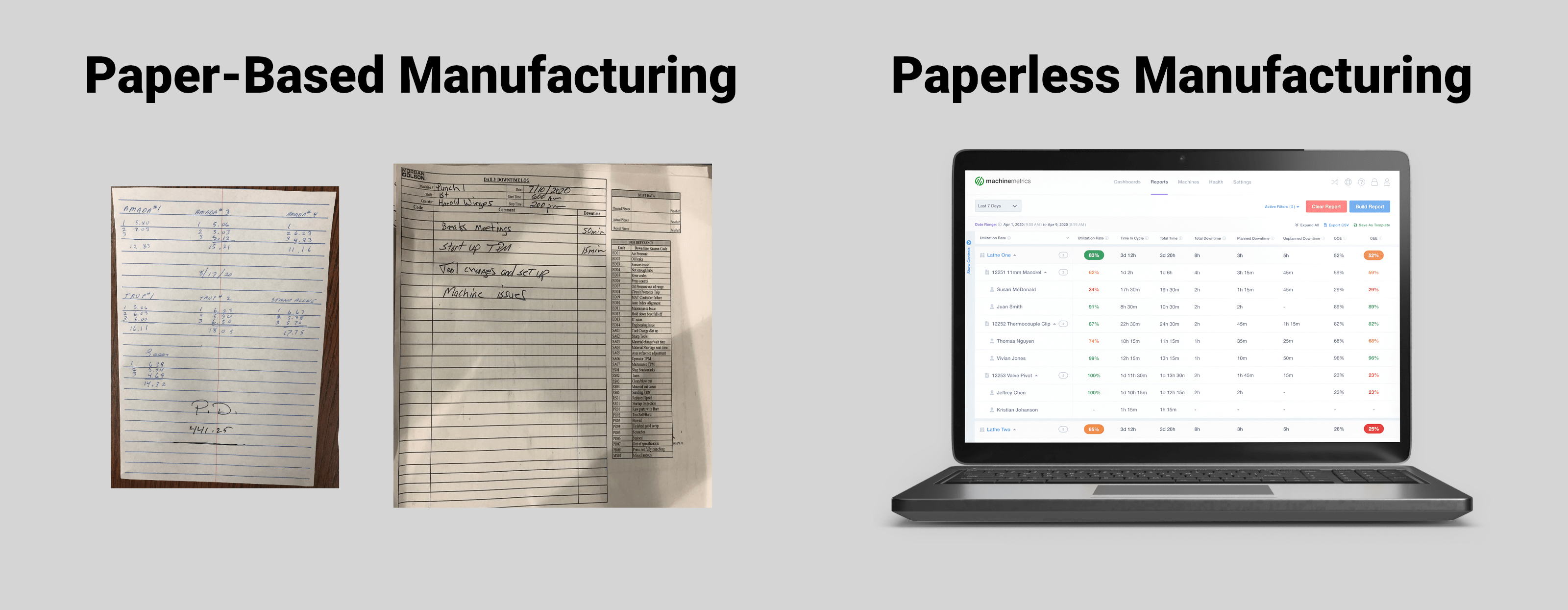

Manufacturing Data Collection Software

Manual shop floor data collection won’t get you to the level you need to compete in modern manufacturing. You can’t manually collect the shop floor data types and levels needed to realize the benefits we’ve discussed thus far. It would be impractical for your employees to spend such large amounts of time manually tracking part counts, downtime reasons, and other shop floor data points. The raw shop floor data would also be nearly unusable and severely delayed.

It would take even further effort from data-savvy employees to manually compact the shop floor data collection by calculating key metrics, developing reports, and sharing the shop floor data collection with all stakeholders.

A manufacturing data collection software system that can automatically collect, contextualize, and share manufacturing information so that your employees can focus on making decisions is a far better scenario.

Requirements you should look for in a system built for manufacturing data collection include:

- Real-time shop floor data collection via the edge. This can simplify data capture and help manage automated tasks that need to occur as close to real-time as possible—such as safety shutoffs—that don’t have time to go to the cloud and back.

- A cloud platform for shop floor data collection and processing. This allows you to utilize powerful resources at a fraction of the cost of purchasing the same equipment to store and analyze data at a deeper level. This includes tools such as exception-based supervisor approvals, links to payroll systems and configurable payroll rules, quality record management, exception reporting, real-time reporting, labor costs, and other detailed reporting for better decision-making.

- Machine integration via the PLC or I/O. This helps to accurately and quickly collect machine data in a way that isn’t prone to error or constant need for adjustment the way some sensors are.

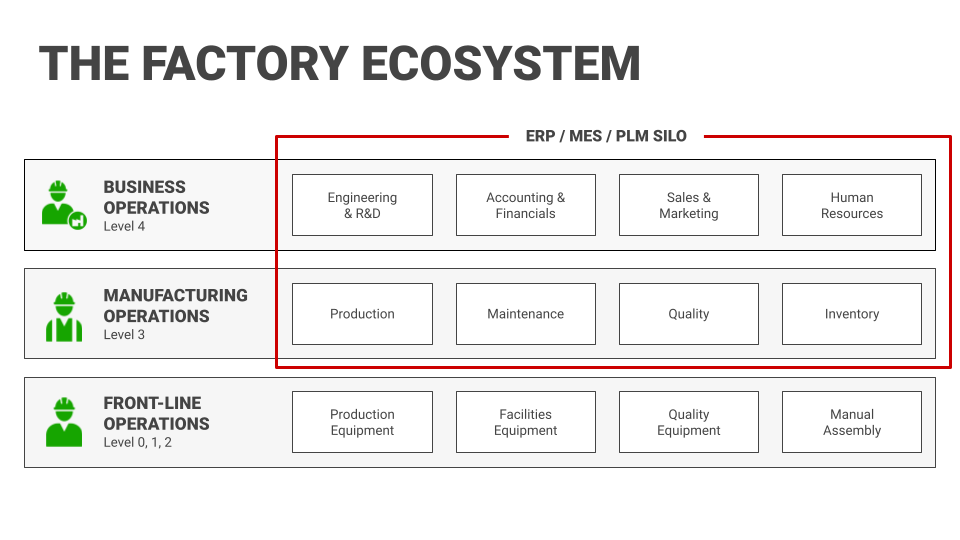

- Integration with other manufacturing software, such as the Manufacturing Execution System (MES), ERP system, CMMS, etc.

- Ability to connect with sensors to ensure data can be collected from a variety of assets, including legacy equipment.

- High-Frequency Data Collection capabilities to leverage as inputs for time series or machine learning models to drive advanced predictive use cases.

Learn how you can use MachineMetrics plug-and-play solutions to easily collect production data and get instant visibility and control of the shop floor.

Ready to connect your shop floor?

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments